General Repair Parts for Blast Pots

Showing 46–60 of 150 results

-

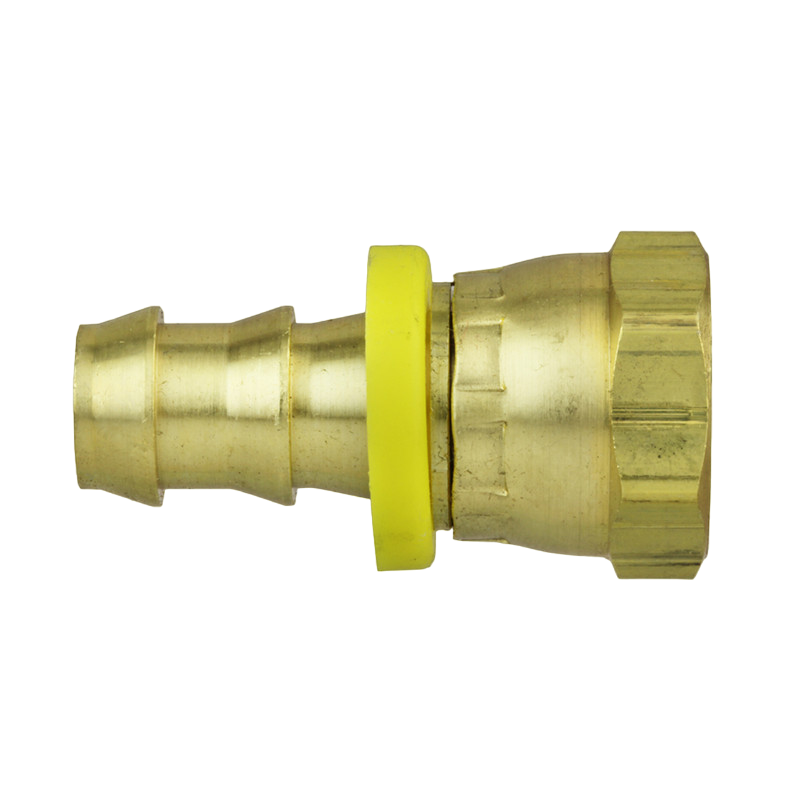

BA50785K273High-pressure brass pipe fitting for use with:

- NPT female threads: Air, Water, BSP and metric threads: air, natural gas, oil, water

BA50785K273High-pressure brass pipe fitting for use with:- NPT female threads: Air, Water, BSP and metric threads: air, natural gas, oil, water

-

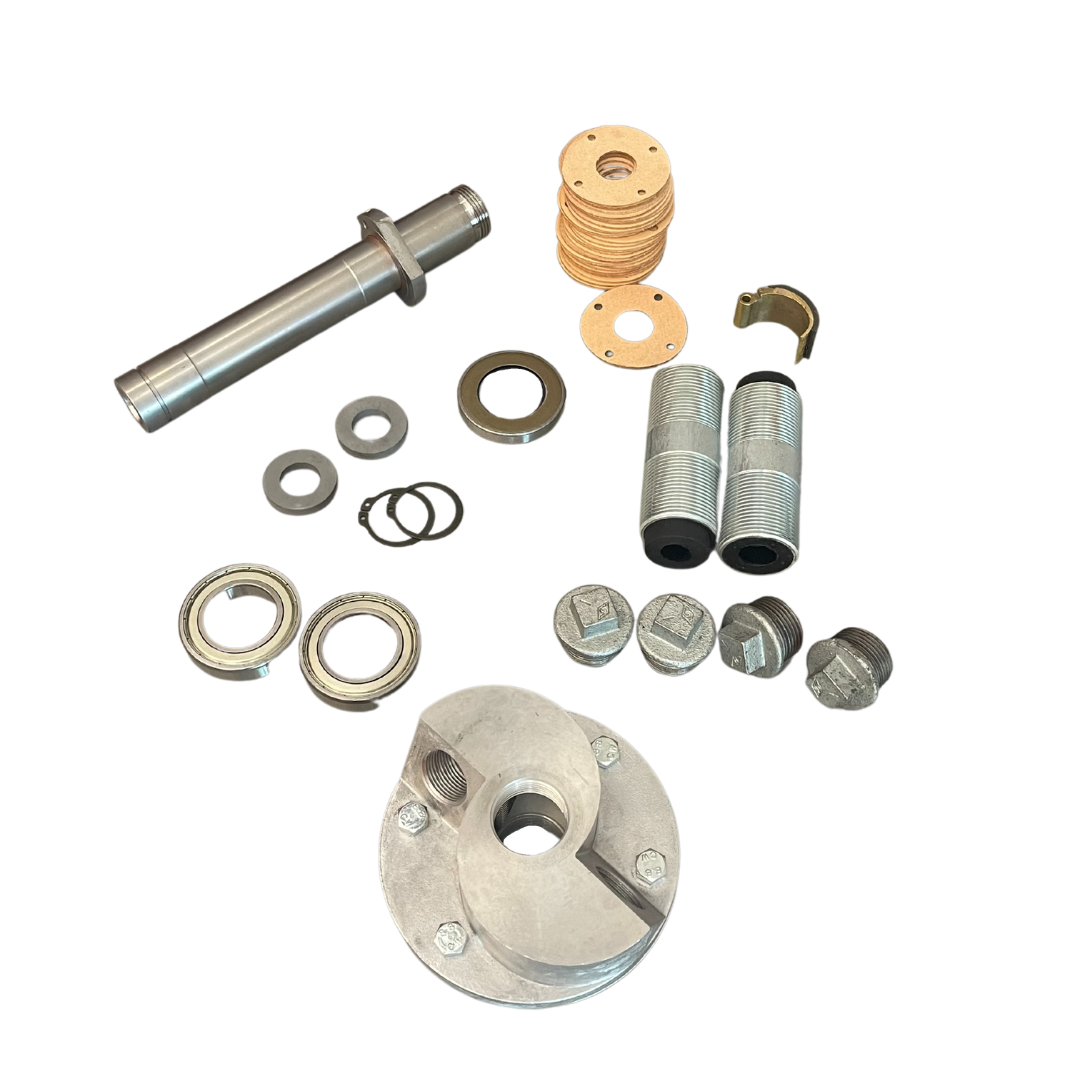

FPSP25

- FPSP25, RB-2 Replacement 1" Threaded Plug

- For IPC1000 RotorBlast

- (Replaces part number IPC1001)

- Note: 4 of these are included in Spare Parts Kit, IPC1099

FPSP25- FPSP25, RB-2 Replacement 1" Threaded Plug

- For IPC1000 RotorBlast

- (Replaces part number IPC1001)

- Note: 4 of these are included in Spare Parts Kit, IPC1099

-

DMMEM200

- Pop-top design, self cleaning

- Installs upright

- 1" (25mm) male thread connection

DMMEM200- Pop-top design, self cleaning

- Installs upright

- 1" (25mm) male thread connection

-

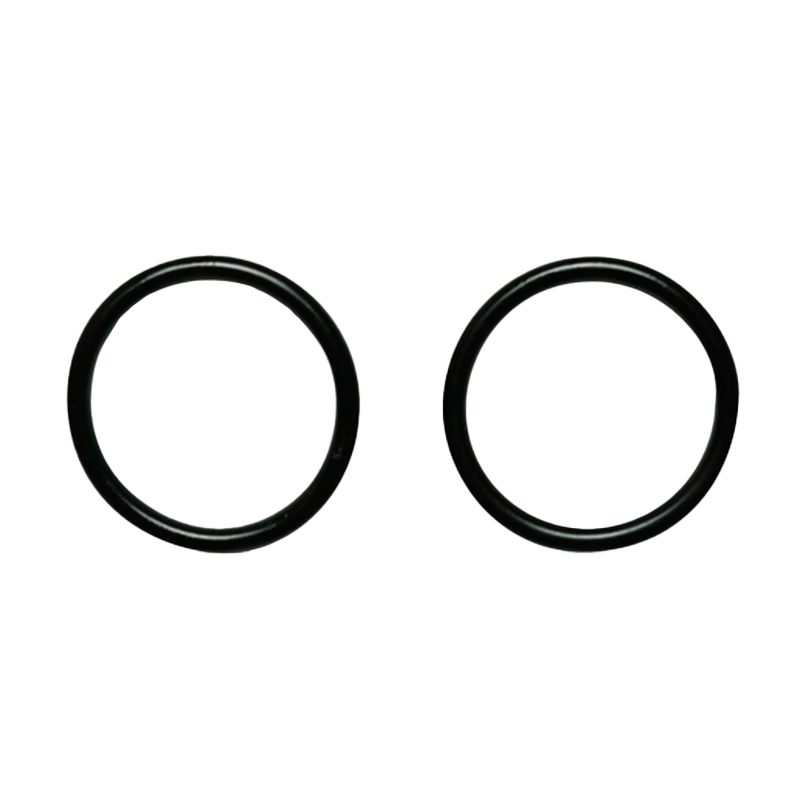

BA02013BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement O-ring set for 1" abrasive trap (factory part number 02013).BA02013BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement O-ring set for 1" abrasive trap (factory part number 02013).

-

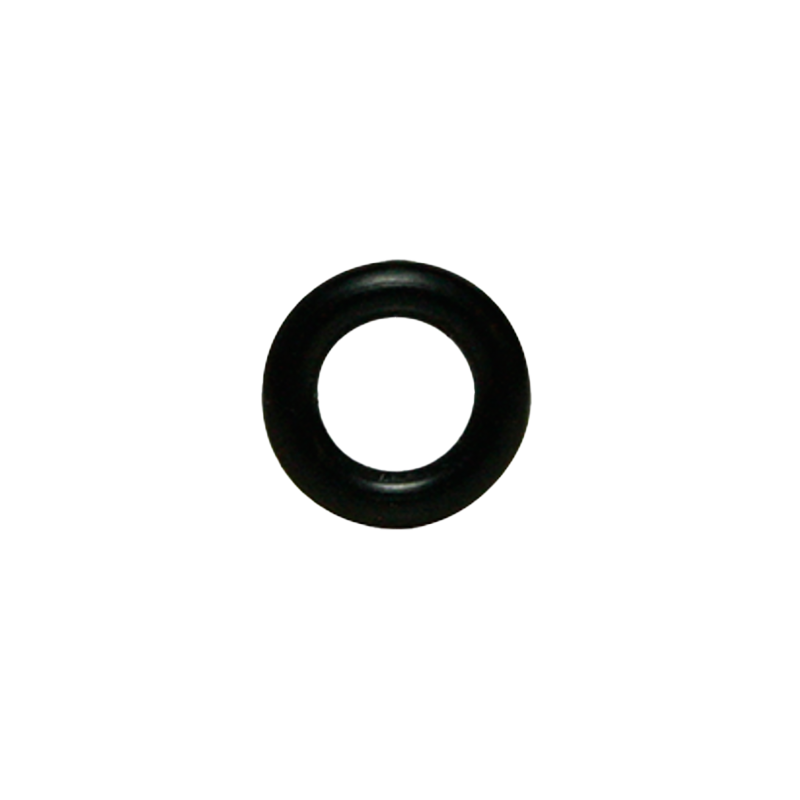

BA01992

BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement 3/16" O-Ring MPN: 01992, for the

- 1" inlet valve

- SG-300 suction gun

- and more

BA01992BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement 3/16" O-Ring MPN: 01992, for the

- 1" inlet valve

- SG-300 suction gun

- and more

-

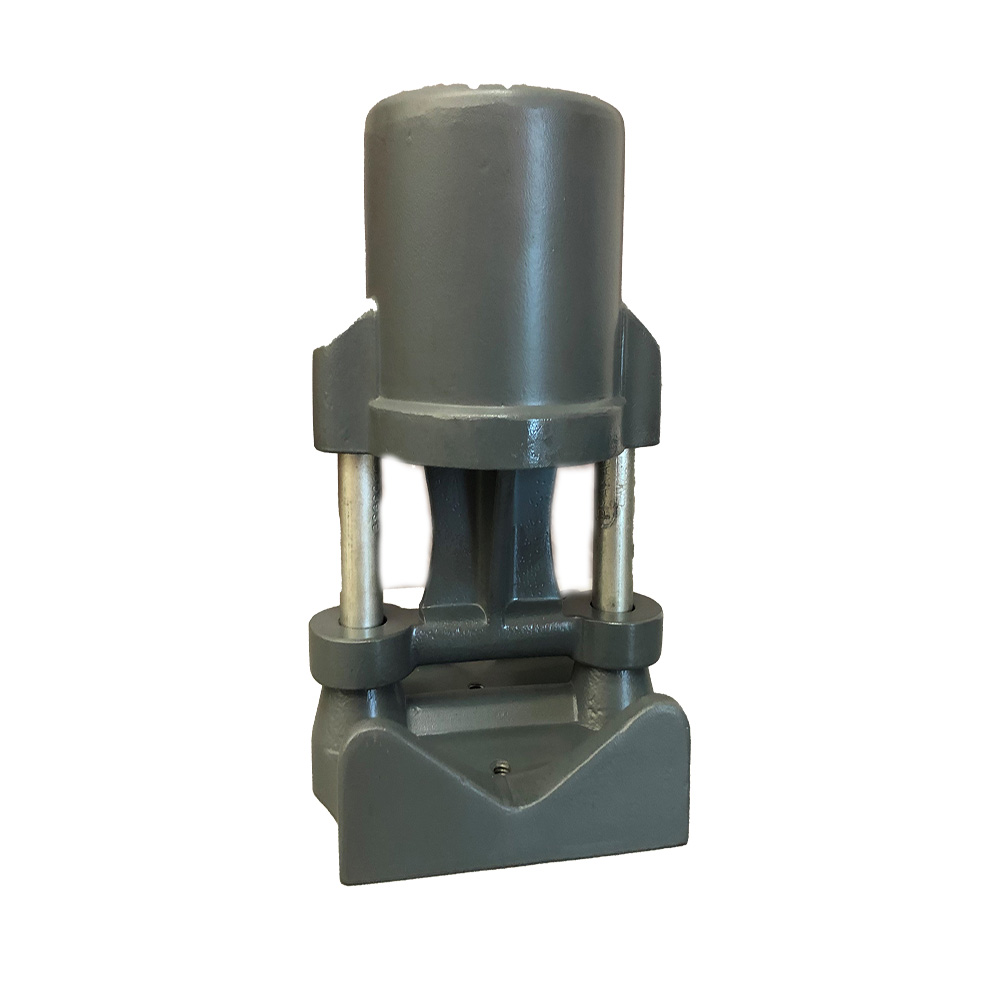

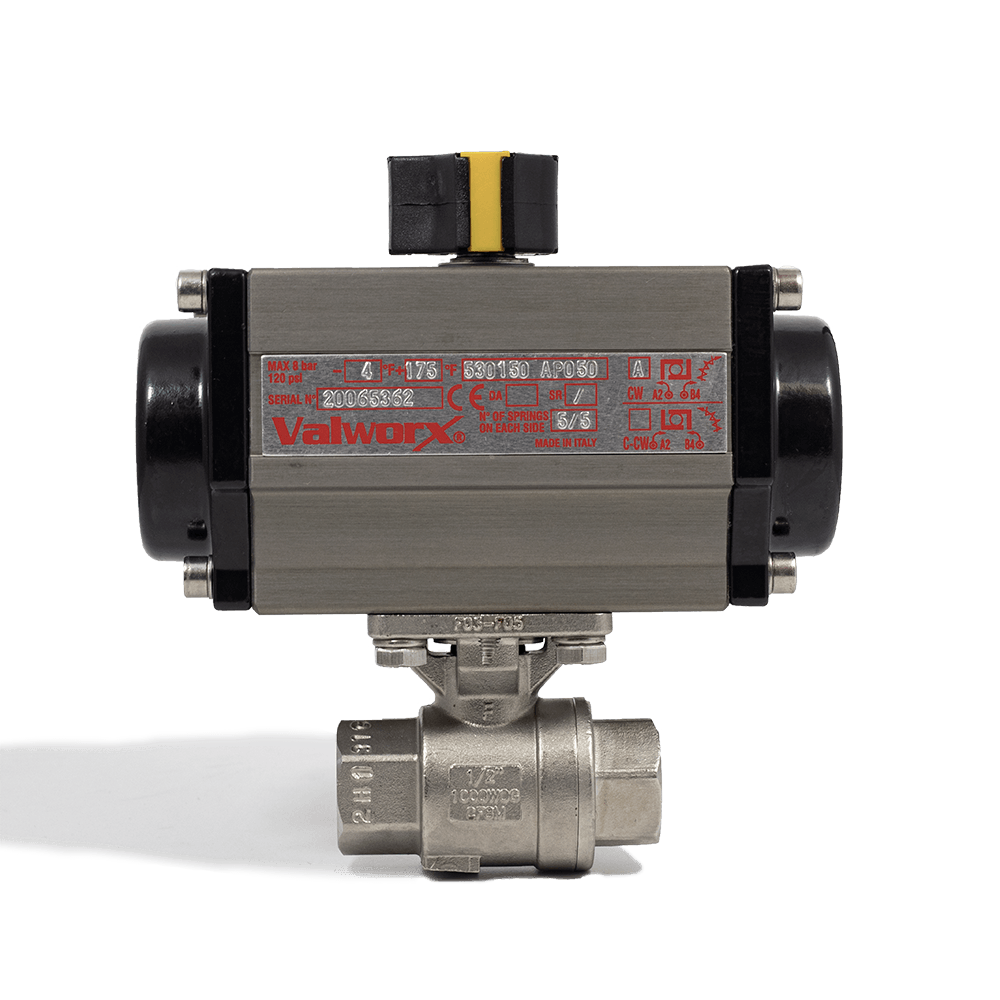

DMPYT400

- Piston-operated valve

- 1/4" female NPT supply air connection

- Effortless activation via deadman control handle

- Guide tubes ensure consistent plunger travel

- Eliminate repressurization down time profit loss

DMPYT400- Piston-operated valve

- 1/4" female NPT supply air connection

- Effortless activation via deadman control handle

- Guide tubes ensure consistent plunger travel

- Eliminate repressurization down time profit loss

-

BA7046003

- Suits Schmidt 3.5 Blast Pot and MistBlaster Secondary Wheel

- 10" Wheel & Tire

- Never Flat, rubber filled tires

- Makes for easy portability onsite

- Sold Individually

- Genuine Parts - Manufactured by Axxiom Manufacturing/Schmidt

BA7046003- Suits Schmidt 3.5 Blast Pot and MistBlaster Secondary Wheel

- 10" Wheel & Tire

- Never Flat, rubber filled tires

- Makes for easy portability onsite

- Sold Individually

- Genuine Parts - Manufactured by Axxiom Manufacturing/Schmidt

-

AFPRGUC200RE

- Suits MistBlaster Blast Machine

- Used to measure the pressure of the blasting and in-coming air

- U-Clamp Panel Mount Gauge

- 2.5" Diameter

- Will measure up to 200 PSI - do not exceed manufacturers recommendation for blast equipment

- Liquid Filled gauge gives you a more steady reading

- Rear Entry gauge

- Sold Individually

AFPRGUC200RE- Suits MistBlaster Blast Machine

- Used to measure the pressure of the blasting and in-coming air

- U-Clamp Panel Mount Gauge

- 2.5" Diameter

- Will measure up to 200 PSI - do not exceed manufacturers recommendation for blast equipment

- Liquid Filled gauge gives you a more steady reading

- Rear Entry gauge

- Sold Individually

-

BA01989BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement bottom cap seal for the inlet valve (factory part number 01989).BA01989BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement bottom cap seal for the inlet valve (factory part number 01989).

-

General purpose air connection fittings

- This is the Reducing Bushing group

- Many sizes available

- Many materials available, including Stainless Steel, Brass, Galvanized Malleable Iron, and Iron

- 150 psi rated

-

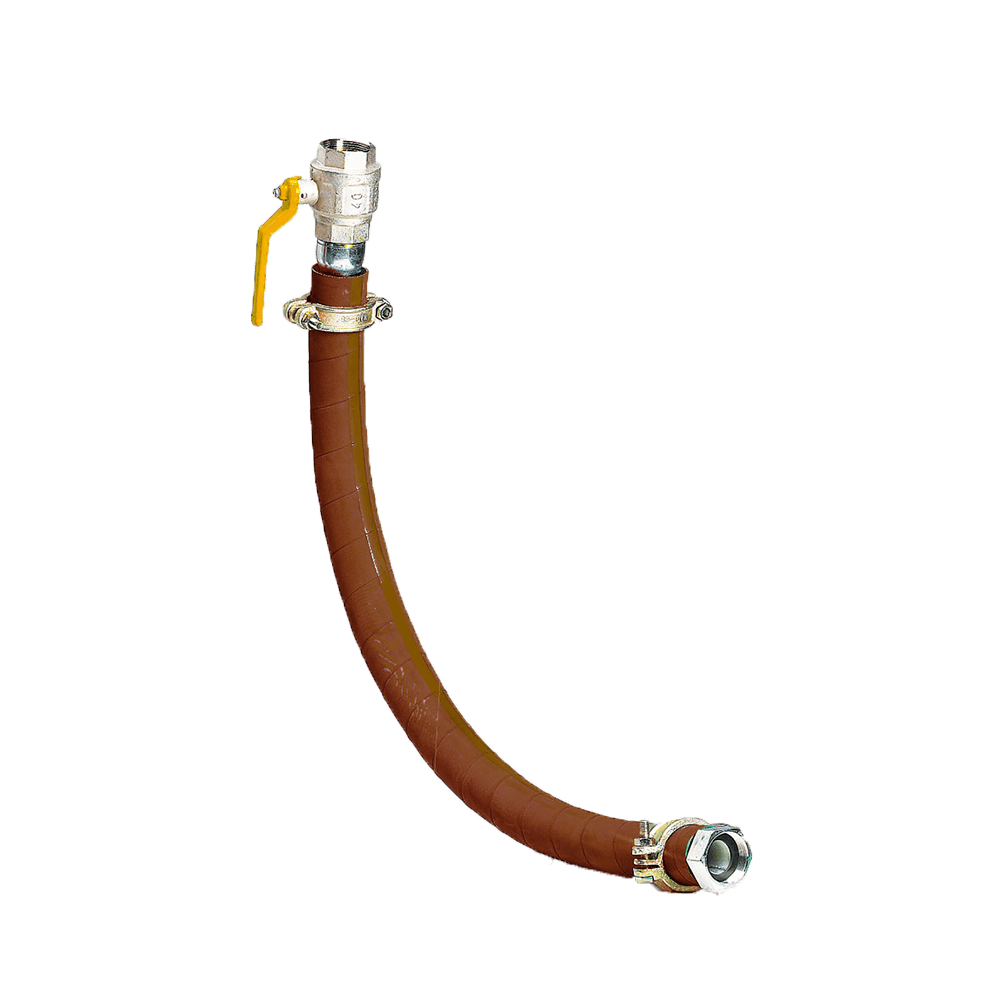

- Hi-flow Blast Pot Pusherline Kit

- Used on Blast Pots between the air control valves and the metering valve

- Sold as a complete assembly Including

- Pusherline Air Hose

- Ball valve

- Nut and tail fittings with bolt style clamps for in-field installation

- Connects to Metering Valve threaded nipple

-

GV01990

BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement 1-¾" O-ring for multiple Clemco valves.

GV01990BlastOne has the parts to maintain your Clemco® blast equipment. This is the replacement 1-¾" O-ring for multiple Clemco valves.

-

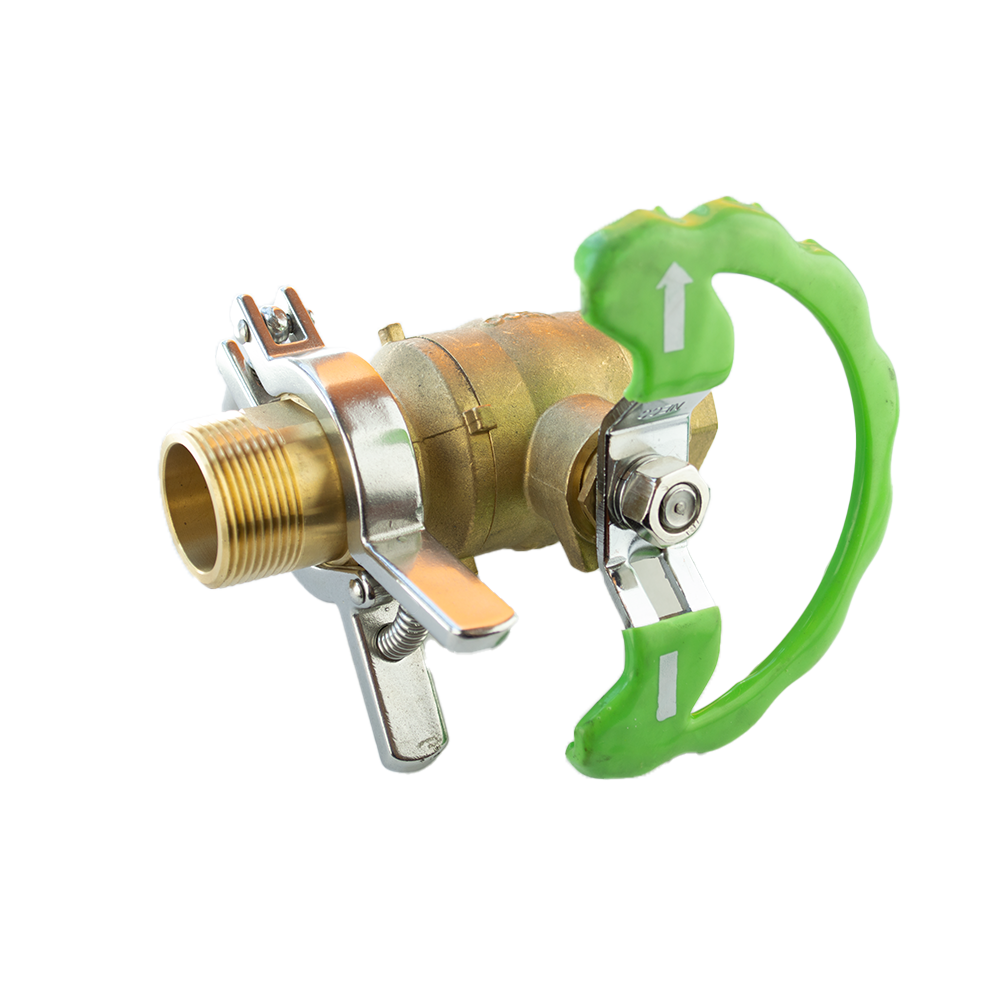

GV2410320SPBV

- Tri-Clover Connector with Built in Ball-Valve

- Locate between the metering valve and the bottom of the pot to reduce maintenance time on the metering valve.

- Combines 2 time savers:

- Tri-Clover connection allows for easy removal of metering valve.

- Ball valve allows for removal of metering valve without emptying the pot.

- 1 1/4" x 1 1/4" NPT Threads - suits most blast pots and abrasive metering valves

- Use thread sealant tape or compound to ensure an airtight connection

- NOTE - this option adds 6 inches in height. Ensure that your pot has the required clearance before ordering, or that you can add the needed height to your existing pot.

GV2410320SPBV- Tri-Clover Connector with Built in Ball-Valve

- Locate between the metering valve and the bottom of the pot to reduce maintenance time on the metering valve.

- Combines 2 time savers:

- Tri-Clover connection allows for easy removal of metering valve.

- Ball valve allows for removal of metering valve without emptying the pot.

- 1 1/4" x 1 1/4" NPT Threads - suits most blast pots and abrasive metering valves

- Use thread sealant tape or compound to ensure an airtight connection

- NOTE - this option adds 6 inches in height. Ensure that your pot has the required clearance before ordering, or that you can add the needed height to your existing pot.

Keep your blast pots in top condition with our comprehensive selection of general repair parts. From essential fittings and pop-up valves to high-pressure union adaptors and brass hose menders, we have everything you need to ensure your equipment operates smoothly and efficiently. Our parts are designed to withstand the rigorous demands of industrial applications, offering durability, reliability, and ease of installation. Browse our extensive inventory to find the exact components you need to maintain your blast pots and keep your operations running seamlessly.

My Account

My Account

Abrasive Metering Valves & Parts

Abrasive Metering Valves & Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts