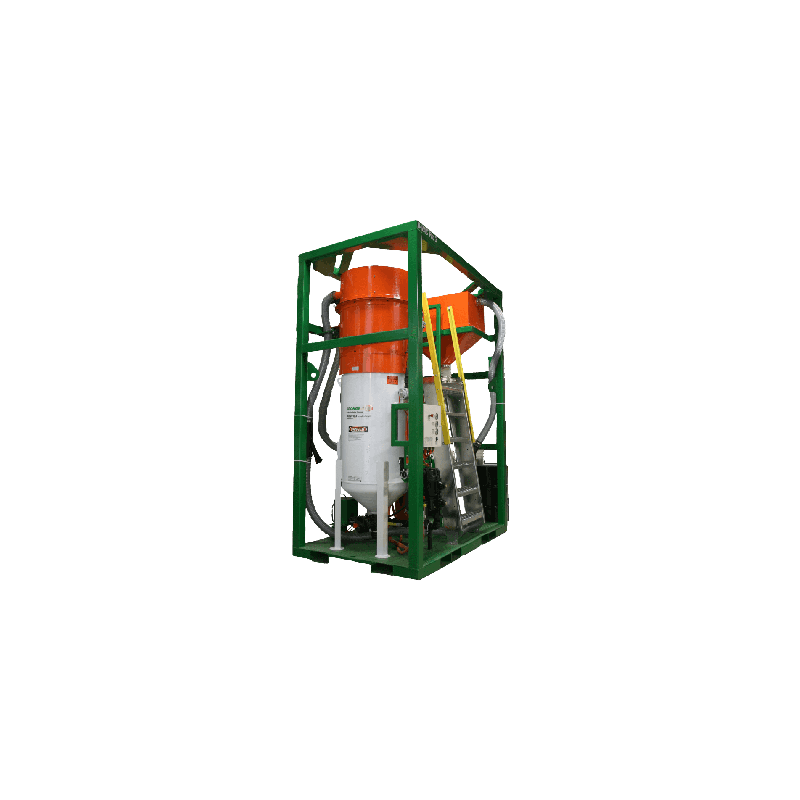

General Repair Parts for Blast Pots

Ensure the longevity and optimal performance of your blast pots with our wide range of general repair parts. Our selection includes high-quality components such as brass fittings, air pressure gauges, and specialty parts like pop-up valves and seating rings. Each part is engineered to meet the highest standards, ensuring reliable operation in demanding environments. If you can’t find what you’re looking for, please contact BlastOne for further assistance or use our live chat feature.

We’re here to support your maintenance needs and help you keep your equipment in peak condition.

Showing 1–15 of 150 results

-

DMRMC01925The Clemco 1-Inch Abrasive Trap Service Kit (MPN: 01925) contains all the necessary components to maintain and service your abrasive trap, ensuring optimal performance and longevity. This genuine Clemco replacement kit includes screens, O-rings, and a screen gasket for reliable operation in abrasive blasting systems. Key Features:

- Includes essential components for abrasive trap maintenance:

- (3) Screens

- (2) O-Rings

- (1) 1/8-inch thick screen gasket

- (1) Clean screen decal

- Genuine Clemco replacement parts for ensured compatibility and reliability.

- Designed to maintain proper function and efficiency of abrasive traps.

DMRMC01925The Clemco 1-Inch Abrasive Trap Service Kit (MPN: 01925) contains all the necessary components to maintain and service your abrasive trap, ensuring optimal performance and longevity. This genuine Clemco replacement kit includes screens, O-rings, and a screen gasket for reliable operation in abrasive blasting systems. Key Features:- Includes essential components for abrasive trap maintenance:

- (3) Screens

- (2) O-Rings

- (1) 1/8-inch thick screen gasket

- (1) Clean screen decal

- Genuine Clemco replacement parts for ensured compatibility and reliability.

- Designed to maintain proper function and efficiency of abrasive traps.

- Includes essential components for abrasive trap maintenance:

-

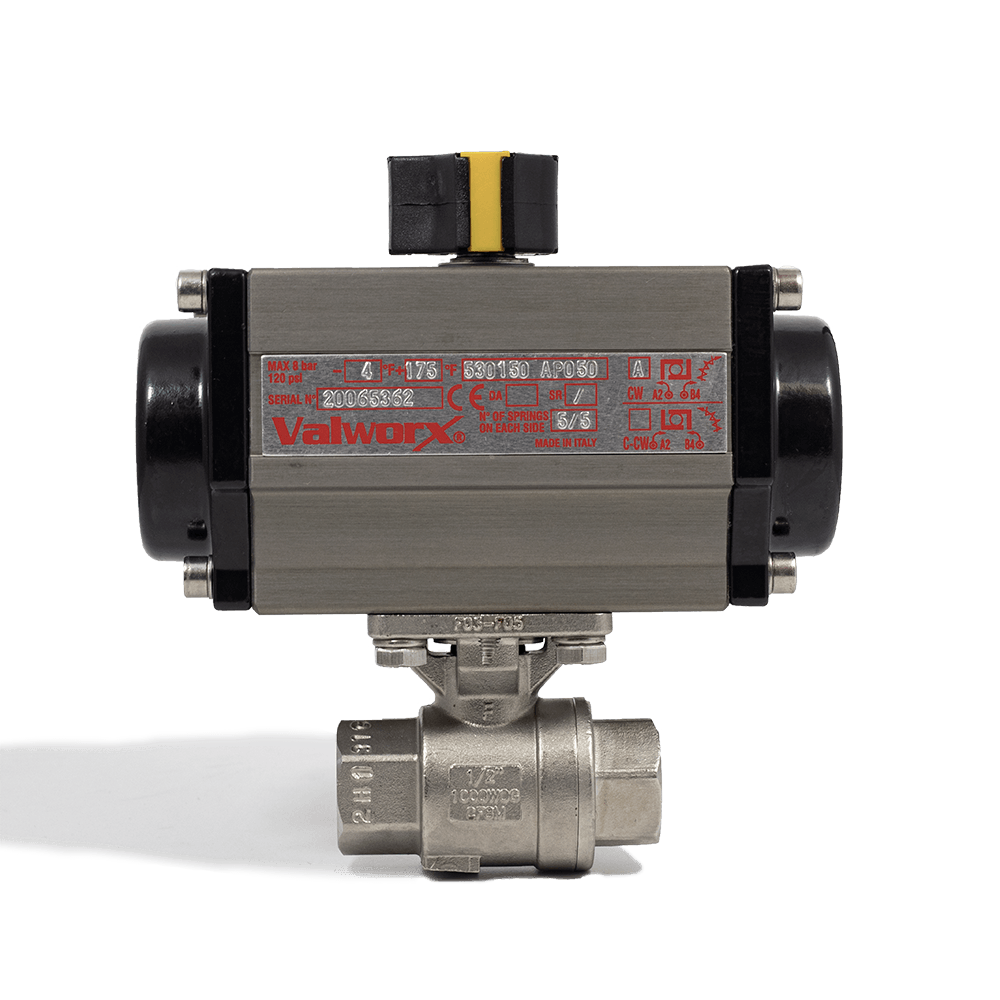

These OEM Clemco Inlet / Outlet Valve Service Kits provide the necessary components to maintain or repair Clemco RMC valves. Choose between available kits for your specific size. Each kit includes springs, O-rings, washers, and other essential parts for reliable performance. Key Features:

- Size options:

- 1/2 inch inlet (MPN: 07814)

- 1-inch inlet (MPN: 01929)

- 1-1/2-inch inlet (MPN: 01927)

- 1" piston outlet (MPN: 01928)

- Contains essential components: springs, O-rings, washers, and more.

- Genuine Clemco repair parts for ensured compatibility and durability.

- Designed to extend the life and efficiency of your inlet valve.

- Size options:

-

BA22529Replacing the Clemco 1-1/4" Male NPT x 1-1/4" JIC Pipe Adapter Fitting (MPN: 22529) is a high-quality adapter designed to connect NPT and JIC (aka flare) threaded components securely. This aftermarket part is compatible with Clemco equipment and provides reliable performance in abrasive blasting setups. Key Features:

- Precision pipe adapter fitting with 1-1/4" Male NPT to 1-1/4" JIC connection.

- Engineered for secure and leak-proof performance in abrasive blasting systems.

- Durable construction to withstand demanding industrial environments.

- Essential for maintaining system integrity and efficiency in blasting applications.

BA22529Replacing the Clemco 1-1/4" Male NPT x 1-1/4" JIC Pipe Adapter Fitting (MPN: 22529) is a high-quality adapter designed to connect NPT and JIC (aka flare) threaded components securely. This aftermarket part is compatible with Clemco equipment and provides reliable performance in abrasive blasting setups. Key Features:- Precision pipe adapter fitting with 1-1/4" Male NPT to 1-1/4" JIC connection.

- Engineered for secure and leak-proof performance in abrasive blasting systems.

- Durable construction to withstand demanding industrial environments.

- Essential for maintaining system integrity and efficiency in blasting applications.

-

Clemco Compression Couplings are OEM replacement parts designed to ensure secure, leak-proof connections in blasting equipment. Available in multiple sizes, these couplings connect the pusher line with the piping on Clemco blast machines. Key Features:

- High-quality replacement compression couplings for Clemco systems.

- Available sizes:

- 1/2"

- 1"

- 1-1/4"

- Engineered for secure, leak-proof connections.

- Genuine Clemco parts ensure optimal compatibility and durability.

- Simple installation reduces downtime and maintenance efforts.

-

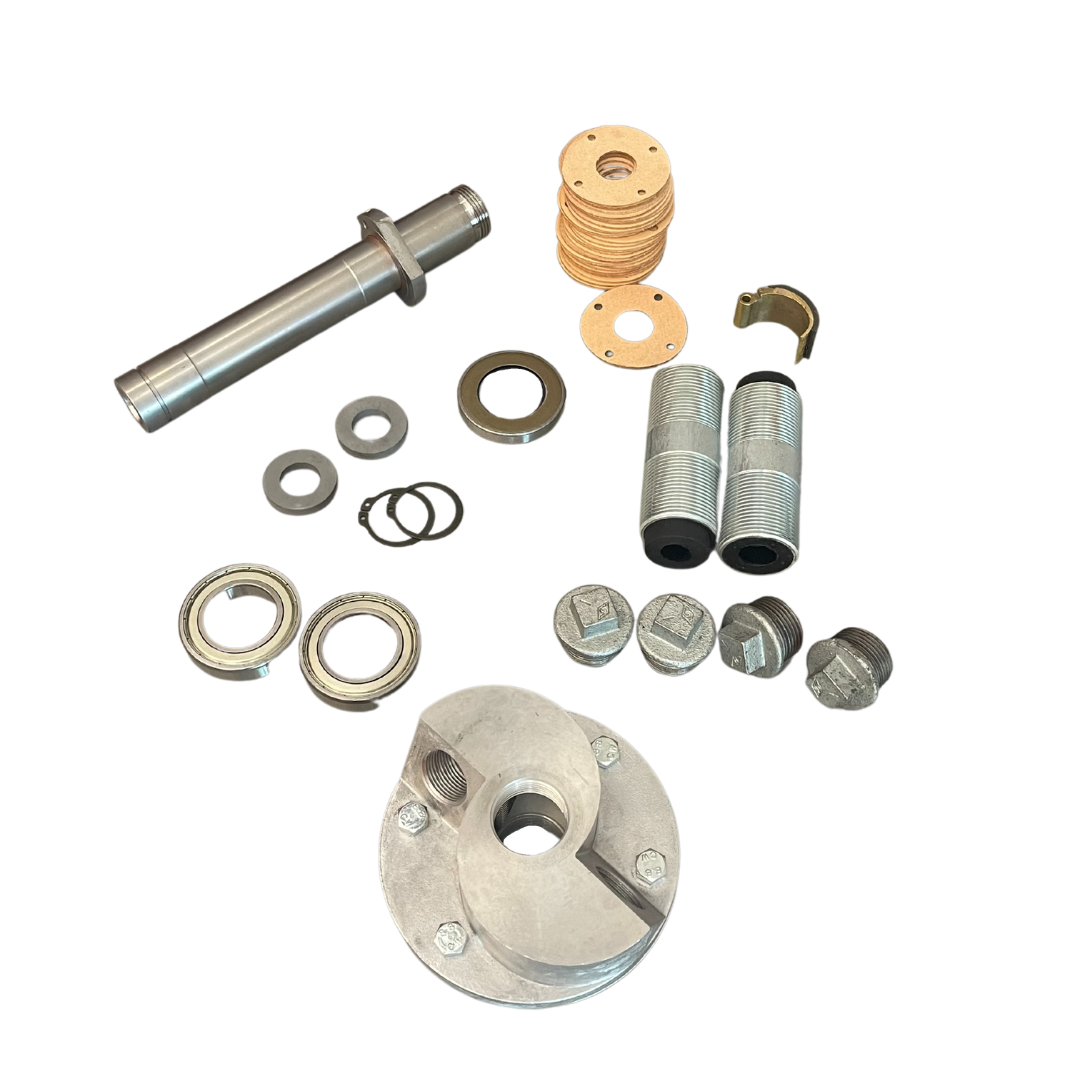

BA22856The Clemco Inlet Seal Service Kit (MPN: 22856) provides all necessary components to maintain and repair your MQV inlet seal. This genuine replacement kit ensures precise fit, reliable performance, and extended equipment longevity. Kit Includes:

- Cylinder Cap Gasket

- U-Seal, dual piston lower, 3-½" ID

- U-Seal, dual piston upper, 2-¾" ID

- 4-1/2" OD O-Ring

- 31/64" ID O-Ring

- (2) 1-3/4" O-Rings (replaces original U-Seals)

BA22856The Clemco Inlet Seal Service Kit (MPN: 22856) provides all necessary components to maintain and repair your MQV inlet seal. This genuine replacement kit ensures precise fit, reliable performance, and extended equipment longevity. Kit Includes:- Cylinder Cap Gasket

- U-Seal, dual piston lower, 3-½" ID

- U-Seal, dual piston upper, 2-¾" ID

- 4-1/2" OD O-Ring

- 31/64" ID O-Ring

- (2) 1-3/4" O-Rings (replaces original U-Seals)

-

The Clemco Manway / Handway Replacement Parts include genuine replacement gaskets and inspection door assemblies for abrasive blasting equipment. Available in all current and legacy model sizes, these parts ensure a secure seal and reliable performance for your Clemco system.

Key Features:

- Replacement **inspection door gaskets** for Clemco equipment.

- Replacement **inspection door assemblies** in standard sizes:

- 3" x 4"

- 4" x 6"

- 6" x 8"

- 14" x 18"

- Provides a tight, leak-proof seal for efficient operation.

- Crafted from durable materials to withstand abrasive blasting environments.

- Genuine Clemco parts for compatibility and reliable performance.

-

DM21731The Clemco Millennium Valve Outlet Segment, Muffler (MPN: 21731) is a genuine replacement part designed to maintain and restore the performance of your Clemco Millennium Valve. This component ensures smooth operation and efficient air exhaust for abrasive blasting systems. Key Features:

- Replacement valve outlet segment, muffler for Clemco Millennium Valve.

- Engineered for efficient air exhaust and noise reduction.

- Durable construction to withstand abrasive blasting conditions.

- Genuine Clemco part ensures precise fit and reliable performance.

- Essential for maintaining valve efficiency and prolonging system life.

DM21731The Clemco Millennium Valve Outlet Segment, Muffler (MPN: 21731) is a genuine replacement part designed to maintain and restore the performance of your Clemco Millennium Valve. This component ensures smooth operation and efficient air exhaust for abrasive blasting systems. Key Features:- Replacement valve outlet segment, muffler for Clemco Millennium Valve.

- Engineered for efficient air exhaust and noise reduction.

- Durable construction to withstand abrasive blasting conditions.

- Genuine Clemco part ensures precise fit and reliable performance.

- Essential for maintaining valve efficiency and prolonging system life.

-

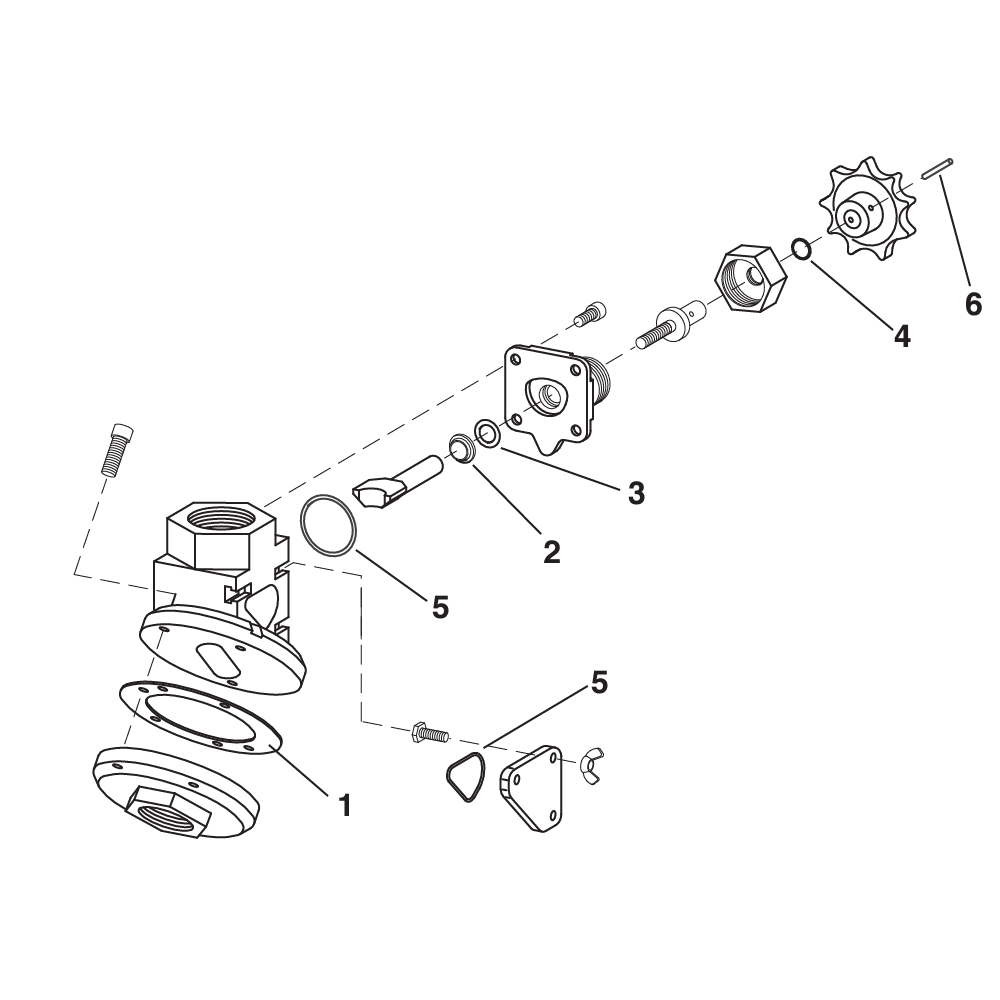

BA22898The Clemco Plunger Tip Service Kit for Millennium Valve (MPN: 22898) provides all the essential components to maintain and repair your Clemco Millennium Valve. This genuine replacement kit ensures optimal valve performance and includes only the parts labeled "++." Key Features:

- Designed specifically for Clemco Millennium Valves.

- Includes parts labeled "++" for efficient servicing.

- Genuine Clemco replacement parts ensure compatibility and reliability.

- Helps maintain peak valve performance and extend service life.

- Easy-to-use kit reduces downtime during maintenance.

BA22898The Clemco Plunger Tip Service Kit for Millennium Valve (MPN: 22898) provides all the essential components to maintain and repair your Clemco Millennium Valve. This genuine replacement kit ensures optimal valve performance and includes only the parts labeled "++." Key Features:- Designed specifically for Clemco Millennium Valves.

- Includes parts labeled "++" for efficient servicing.

- Genuine Clemco replacement parts ensure compatibility and reliability.

- Helps maintain peak valve performance and extend service life.

- Easy-to-use kit reduces downtime during maintenance.

-

The Clemco Pop-Up Guides are OEM replacement parts designed for all Clemco pop-up type blasting pots. Available in multiple sizes, these internal pop-up guides ensure optimal performance and longevity for your Clemco equipment. Key Features:

- Designed for all Clemco units with pop-up assemblies

- Available size options:

- 1-1/4" x 5" toe

- 1-1/4" x 6" toe

- 1-1/4" x 6-1/2" toe

- 1-1/4" x 9-1/2" toe

- Made from durable materials for extended service life.

- Authentic Clemco replacement parts to maintain equipment reliability.

- Easy to install for minimal downtime.

-

BA22854The Clemco Service Kit for MQV Metering Segment (MPN: 22854) provides all necessary components to maintain and repair your MQV metering segment. This genuine replacement kit ensures precise fit, reliable performance, and extended equipment longevity. Kit Includes:

- Flange Gasket

- Wiper Seal

- 3/4" O-Ring

- 5/8" O-Ring

- 1-1/2" O-Ring

- Roll Pin

BA22854The Clemco Service Kit for MQV Metering Segment (MPN: 22854) provides all necessary components to maintain and repair your MQV metering segment. This genuine replacement kit ensures precise fit, reliable performance, and extended equipment longevity. Kit Includes:- Flange Gasket

- Wiper Seal

- 3/4" O-Ring

- 5/8" O-Ring

- 1-1/2" O-Ring

- Roll Pin

-

The Clemco Blast Cabinet Window Gaskets are durable, high-performance OEM parts designed to create a secure, airtight seal for Clemco blast cabinet and blast room windows. Sold by the foot, this gasket prevents dust, media, and debris from escaping during abrasive blasting. Features:

- Application: Designed for the cabinet side, not the window itself.

- Secure Seal: Prevents air leaks and ensures a clean blasting environment.

- Durable Material: Built to withstand abrasive blasting conditions.

- Sizing Options: Available in 5/16" x 3/4", 5/32" x 3/4", and 5/8" x 2-1/2".

- Usage: Typically, 6 feet are required to seal a standard cabinet. Sold by the foot for customizable lengths.

-

- Swiveling nut for easy fit-up - nut 'locks up' rigid when tightened (NPTFSW)

- Steel

- 4:1 Safety Factor

-

Clemco Brass Fittings ensure secure, corrosion-resistant connections in harsh industrial environments. Shop here for the flared (JIC) fittings, NPT fittings and more that you need for control valves, metering valves, and hoses!

-

OEM Clemco blast machine lids and screens are useful accessories for many applications. Lids keep the pots from collecting debris - especially when used outdoors. Screens are highly recommended for preventing foreign matter out of the pot when refilling abrasive. They are standard with most new Clemco blast machine packages, but lids are optional. Both are available here in sizes to match any size blast pot from 0.5CF (10") to 20 CF (36").

Keep your blast pots in top condition with our comprehensive selection of general repair parts. From essential fittings and pop-up valves to high-pressure union adaptors and brass hose menders, we have everything you need to ensure your equipment operates smoothly and efficiently. Our parts are designed to withstand the rigorous demands of industrial applications, offering durability, reliability, and ease of installation. Browse our extensive inventory to find the exact components you need to maintain your blast pots and keep your operations running seamlessly.

My Account

My Account

Abrasive Metering Valves & Parts

Abrasive Metering Valves & Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts