Abrasive Metering Valves & Parts

Showing 16–30 of 122 results

-

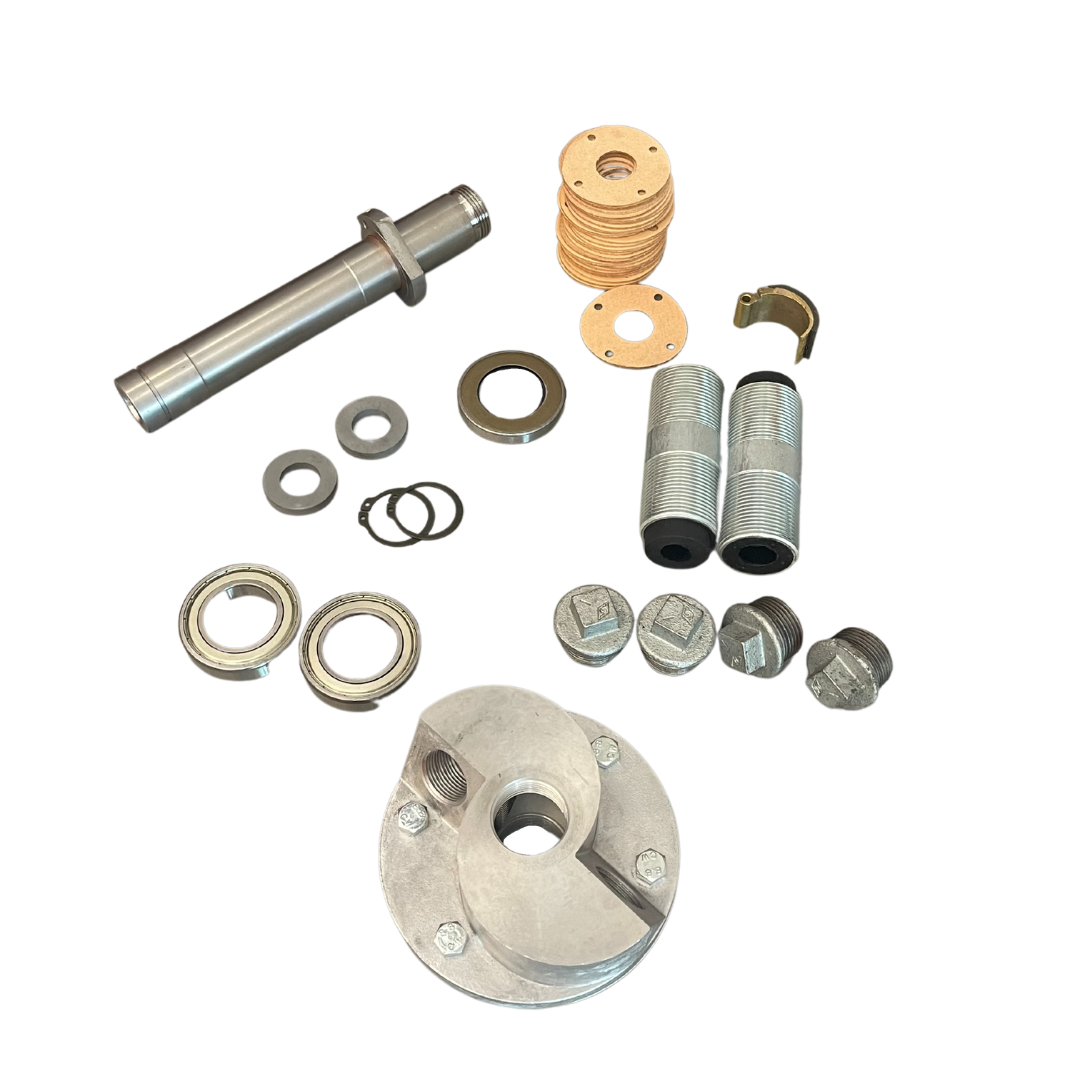

The Schmidt Thompson® Valve II Blast Pot Retrofit Kit converts your existing blast pot into a pressure-hold system, reducing downtime and improving efficiency. Designed for stop/start blasting and multi-outlet blast machines, this OEM Schmidt®/Axxiom kit includes all necessary components for fast-response remote control operation.

Included in the Retrofit Kit:

- Thompson® Valve Series II Metering Valve

- Full pusherline kit

- Automatic air valve with interconnecting hoses

- Control line strainer and control valve

- Response deadman handle and Twinline

- Note: Does not include muffler or pressure relief valve

-

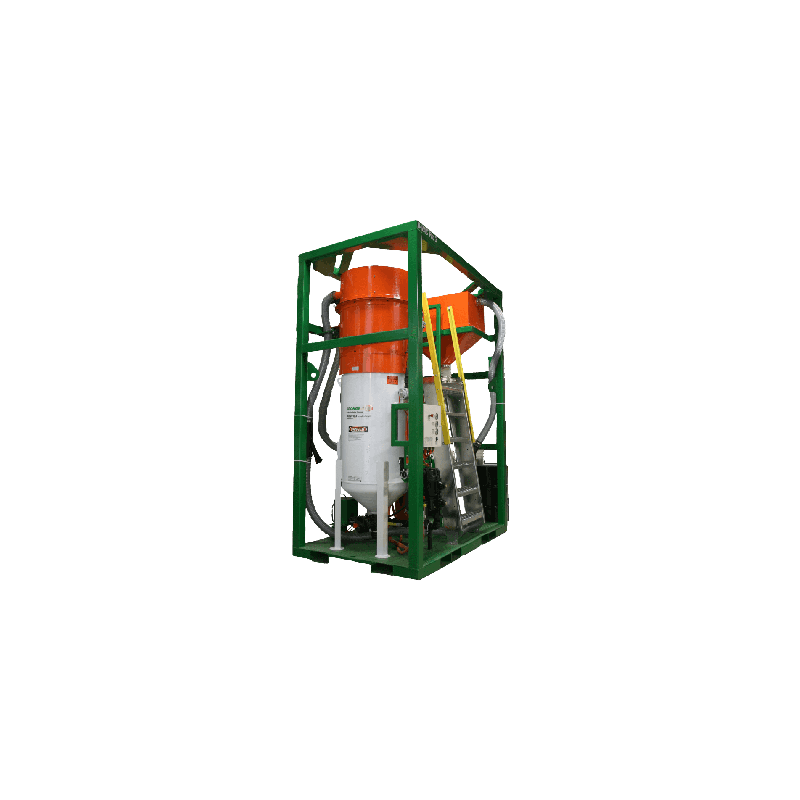

Inefficient or non-functional blast machines can be refurbished / upgraded to become state-of-the-art by installing a Retrofit kit - saving thousands versus buying a new pot! (Pot must be structurally sound.) The Schmidt Combo and Micro Valve System Retrofit Kit is designed for those who want fail-safe pressure-release operation. Available in electric or pneumatic configurations, this kit includes everything needed for a simple retrofit installation, ensuring reliable operation and easy maintenance. Included in the Kit:

- 1 1/4" Combo Valve – Provides efficient pressure-release functionality

- MicroValve 3 – Ensures precise abrasive metering with choice of pipe nipple sizes

- Full pusherline kit – Complete setup for smooth media flow, size matched to the MV3

- All interconnecting hoses and fittings – Simplifies installation

- Control line strainer and control valve – Enhances system reliability

- Response deadman handle and Deadman line – Safety-focused operation. Available in the G2 Paddle type or the BAABS with the G3 Trigger type.

-

DM2152ACSThis kit includes all parts needed to change from blasting to blow-off at the flip of a switch at the deadman. Eliminates need for a separate air-hose or trekking back to the pot to shut off the abrasive. This version is for pots with an existing Thompson 2 valve and pneumatic controls.DM2152ACSThis kit includes all parts needed to change from blasting to blow-off at the flip of a switch at the deadman. Eliminates need for a separate air-hose or trekking back to the pot to shut off the abrasive. This version is for pots with an existing Thompson 2 valve and pneumatic controls.

-

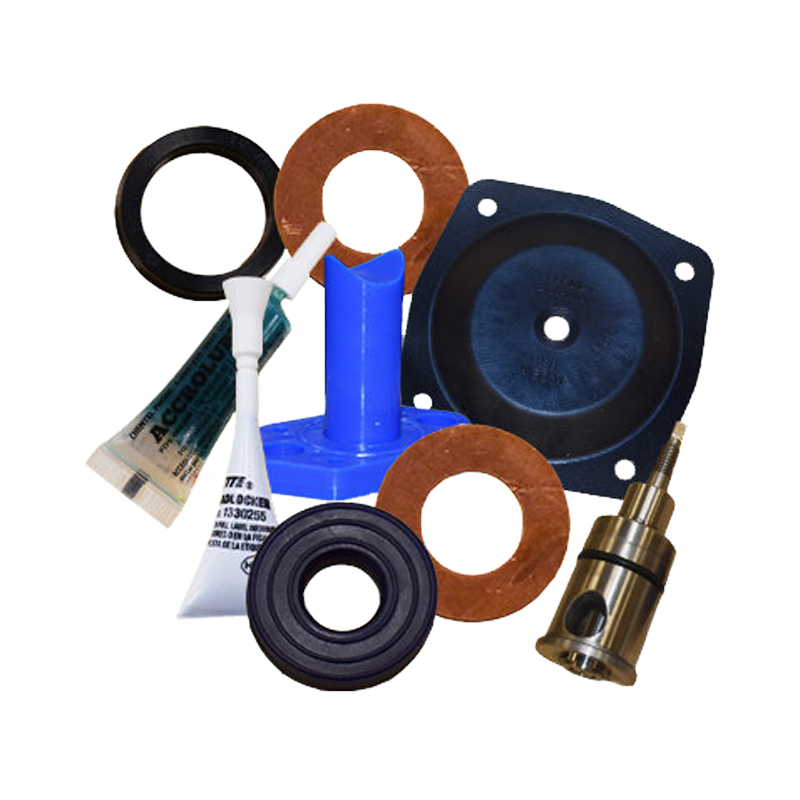

GV215300099

- OEM Complete Rebuild Kit for Thompson® Valve II XL™

- Replacement Plunger, and Sleeve (w/ Wiper), Replacement Seals and O-Rings

- Schmidt® / Axxiom part # 2153-000-99

GV215300099- OEM Complete Rebuild Kit for Thompson® Valve II XL™

- Replacement Plunger, and Sleeve (w/ Wiper), Replacement Seals and O-Rings

- Schmidt® / Axxiom part # 2153-000-99

-

Thompson II Valve Rebuild kits include the most common wear items, and are available as seals-only, or with the tungesten carbide plunger included. Geniune Axxiom parts!

-

GV214900099

- OEM Complete Rebuild Kit for the Thompson® Valve I

- Replacement Seals, Tungsten Carbide Plunger & Sleeve

- Schmidt® / Axxiom part # 2149-000-99

- Includes: GV214900004, GV214900006, GV214900007, GV214900010, GV214900013, GV214900014, and GV214900018

GV214900099- OEM Complete Rebuild Kit for the Thompson® Valve I

- Replacement Seals, Tungsten Carbide Plunger & Sleeve

- Schmidt® / Axxiom part # 2149-000-99

- Includes: GV214900004, GV214900006, GV214900007, GV214900010, GV214900013, GV214900014, and GV214900018

-

GV213000099

- OEM Rebuild Kit for TeraValve™ XL

- Includes Tungsten Carbide Sleeve & Plunger along with Seal kit

- Schmidt® / Axxiom part # 2130-000-99

- Includes: GV213000004, GV213000006, GV213000007, GV213000008, GV213000009, GV213000010

GV213000099- OEM Rebuild Kit for TeraValve™ XL

- Includes Tungsten Carbide Sleeve & Plunger along with Seal kit

- Schmidt® / Axxiom part # 2130-000-99

- Includes: GV213000004, GV213000006, GV213000007, GV213000008, GV213000009, GV213000010

-

GV213000098

- OEM Repair Kit for TeraValve XL

- Replacement Diaphragm, Seals, & O-Rings only

- Schmidt / Axxiom part # 2130-000-98

- Includes: GV213000004, GV213000008, GV213000009, GV213000010

GV213000098- OEM Repair Kit for TeraValve XL

- Replacement Diaphragm, Seals, & O-Rings only

- Schmidt / Axxiom part # 2130-000-98

- Includes: GV213000004, GV213000008, GV213000009, GV213000010

-

GV212810099Revitalize your MicroValve 3 with the Schmidt MicroValve 3 Complete Rebuild Kit (SKU: GV212810099). This comprehensive OEM replacement kit, complete with plunger, ensures optimal functionality and extended valve life.

- OEM Rebuild Kit suit MicroValve 3 - Includes Plunger

- Schmidt / Axxiom part # 2128-100-99

- Includes: GV7011005060, 2127-000-05, GV214950006, GV212810008, GV212800015

GV212810099Revitalize your MicroValve 3 with the Schmidt MicroValve 3 Complete Rebuild Kit (SKU: GV212810099). This comprehensive OEM replacement kit, complete with plunger, ensures optimal functionality and extended valve life.- OEM Rebuild Kit suit MicroValve 3 - Includes Plunger

- Schmidt / Axxiom part # 2128-100-99

- Includes: GV7011005060, 2127-000-05, GV214950006, GV212810008, GV212800015

-

GV212510099

- OEM Complete Service Kit suit MicroValve® 1

- Schmidt / Axxiom Part # 2125-100-99

- Includes 1 (ea) of GV212500004, GV212500005, GV212500009, GV212510008, and GV214800006

GV212510099- OEM Complete Service Kit suit MicroValve® 1

- Schmidt / Axxiom Part # 2125-100-99

- Includes 1 (ea) of GV212500004, GV212500005, GV212500009, GV212510008, and GV214800006

-

GV212710099

- Repair Kit for MicroValve

- Replacement Repair Kit for MicroValve III

- Schmidt abrasive blasting equipment/ Axxiom Manufacturing part number 2127-100-99

- Complete Rebuild Kit for MicroValve 2 Schmidt / Axxiom part # 2127-100-99 Includes: GV214950006, GV212700005, GV701100506, GV212700012, GV212700015, and GV212710008

GV212710099- Repair Kit for MicroValve

- Replacement Repair Kit for MicroValve III

- Schmidt abrasive blasting equipment/ Axxiom Manufacturing part number 2127-100-99

- Complete Rebuild Kit for MicroValve 2 Schmidt / Axxiom part # 2127-100-99 Includes: GV214950006, GV212700005, GV701100506, GV212700012, GV212700015, and GV212710008

-

GV215300098

- OEM Replacement Seals Kit for Thompson® Valve II XL™

- Replacement Seals / O-Rings only

- Schmidt® / Axxiom part # 2153-000-98

GV215300098- OEM Replacement Seals Kit for Thompson® Valve II XL™

- Replacement Seals / O-Rings only

- Schmidt® / Axxiom part # 2153-000-98

-

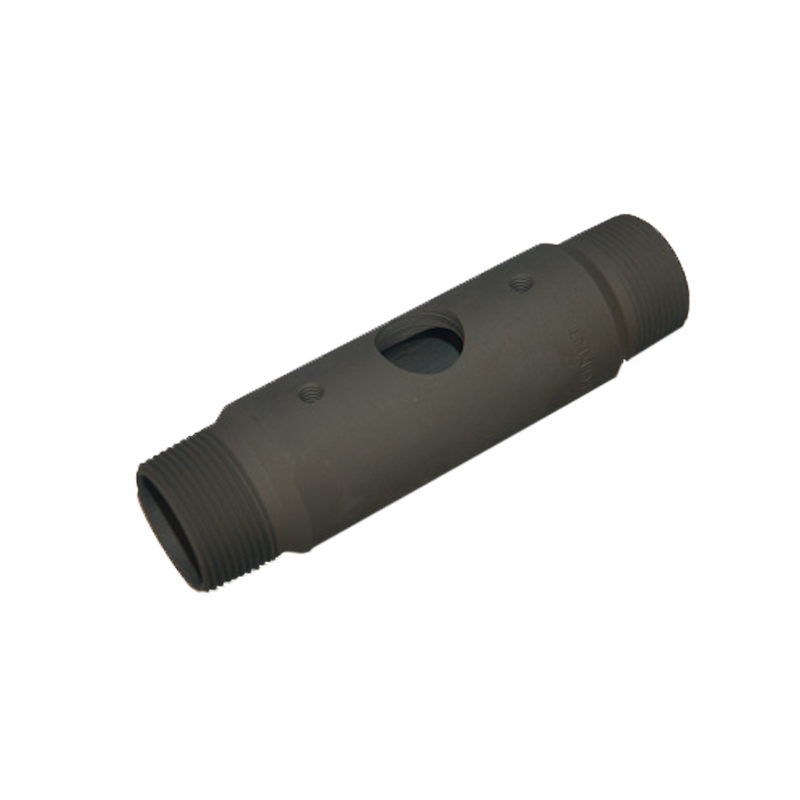

BlastOne has the repair parts you need to maintain your Schmidt® Thompson II metering valves. Replacement sleeves are available in several variants as follows:

- Urethane - recommended for steel shot/grit

- Tungsten Carbide - recommended longer life sleeve for applications other than steel shot/grit

- Tungsten Carbide Keyslot - specialized port shaped like a keyhole, prevents overconsumption of abrasive even if the valve is wide open.

- Multi-Port Sleeve - offers multiple port sizes, designed to prevent overconsumption of abrasive in various mesh sizes

-

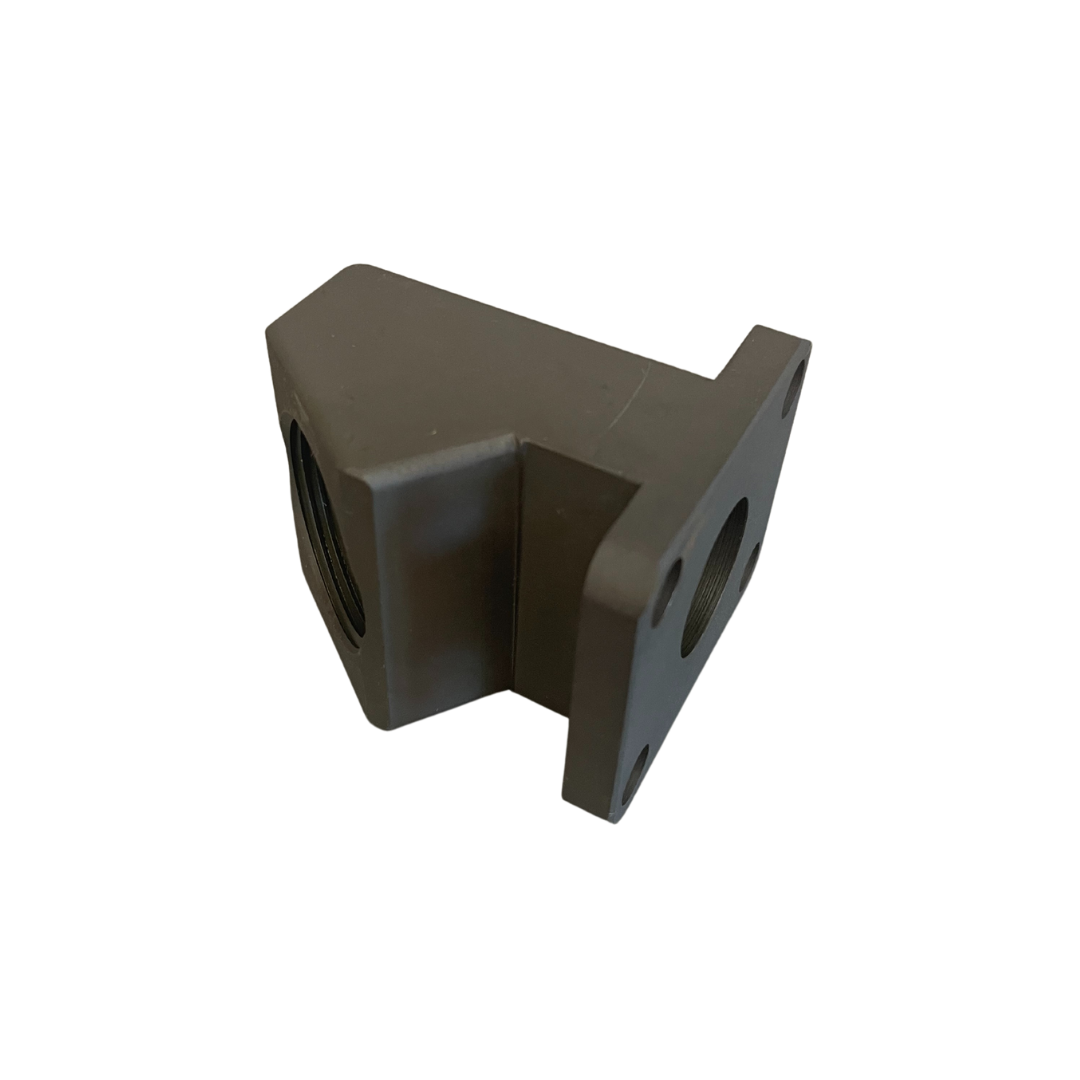

GV215230715

- Replacement direct down base for the 2152-009 Schmidt Jumbo Thompson II Abrasive Metering Valve

- MPN 2152-307-15

GV215230715- Replacement direct down base for the 2152-009 Schmidt Jumbo Thompson II Abrasive Metering Valve

- MPN 2152-307-15

My Account

My Account

Abrasive Metering Valves

Abrasive Metering Valves Abrasive Metering Valve Parts

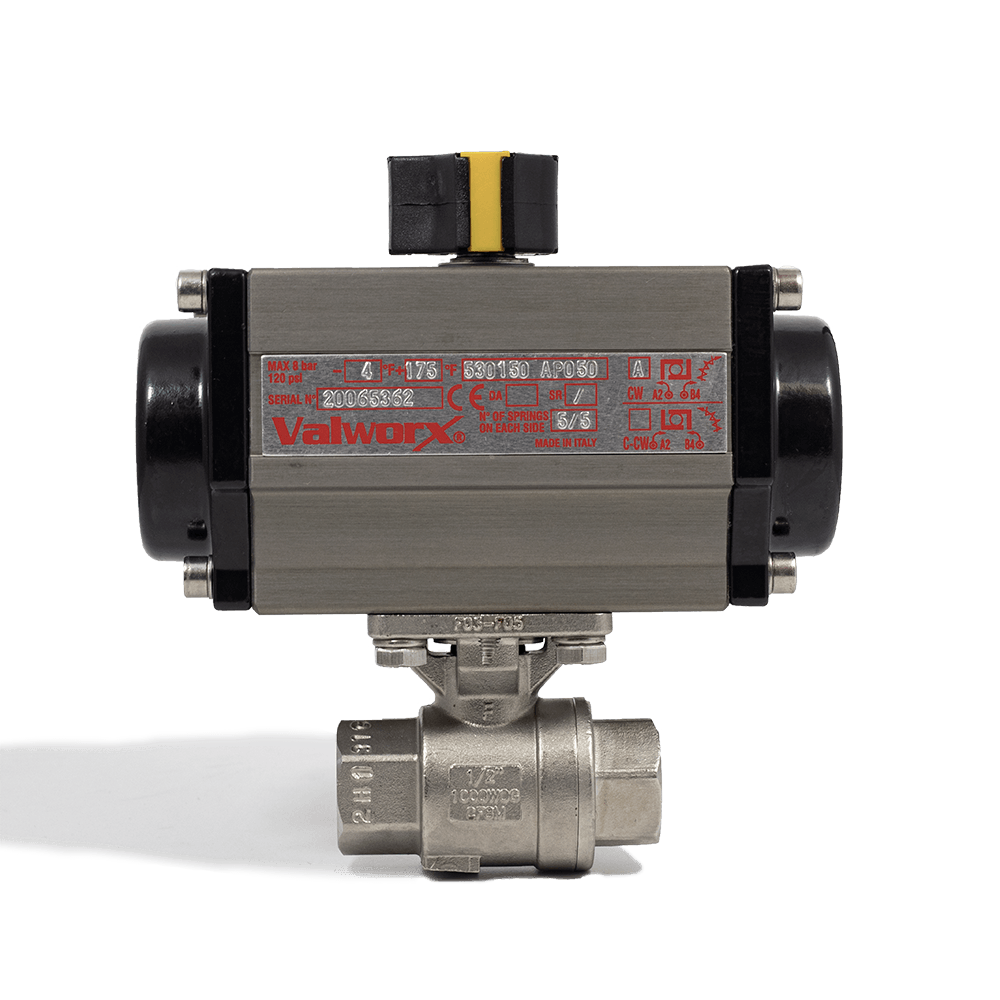

Abrasive Metering Valve Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems General Repair Parts for Blast Pots

General Repair Parts for Blast Pots Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts