Air Dryers

Air Prep Systems

Having dry and high pressure (above 100 psi) compressed air is an essential ingredient in an industrial sandblasting operation. Whether you are blasting in the open or in an enclosed industrial blasting room, an ample supply of dry compressed air will make your job easier, make your sandblasting production more efficient and dramatically reduce downtime and time wastage due to blast abrasive clumping. It has the added advantage of being able to optimize your grit valve or abrasive valve – to reduce abrasive consumption. The best and most economical method of removing moisture from the compressed air stream – is using a air prep system or sandblasting air dryer. These abrasive blasting air dryers have large ports and non-restricted air passages which results in no or minimal pressure loss/pressure drop through the air prep system.

Showing 1–15 of 20 results

-

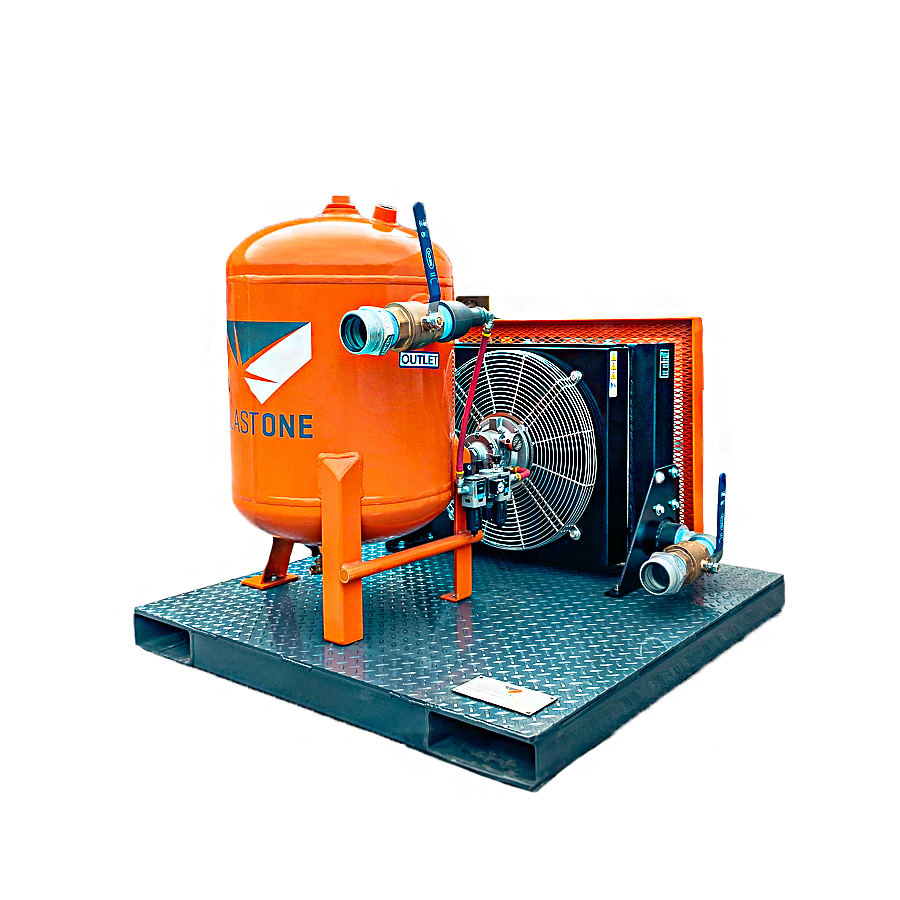

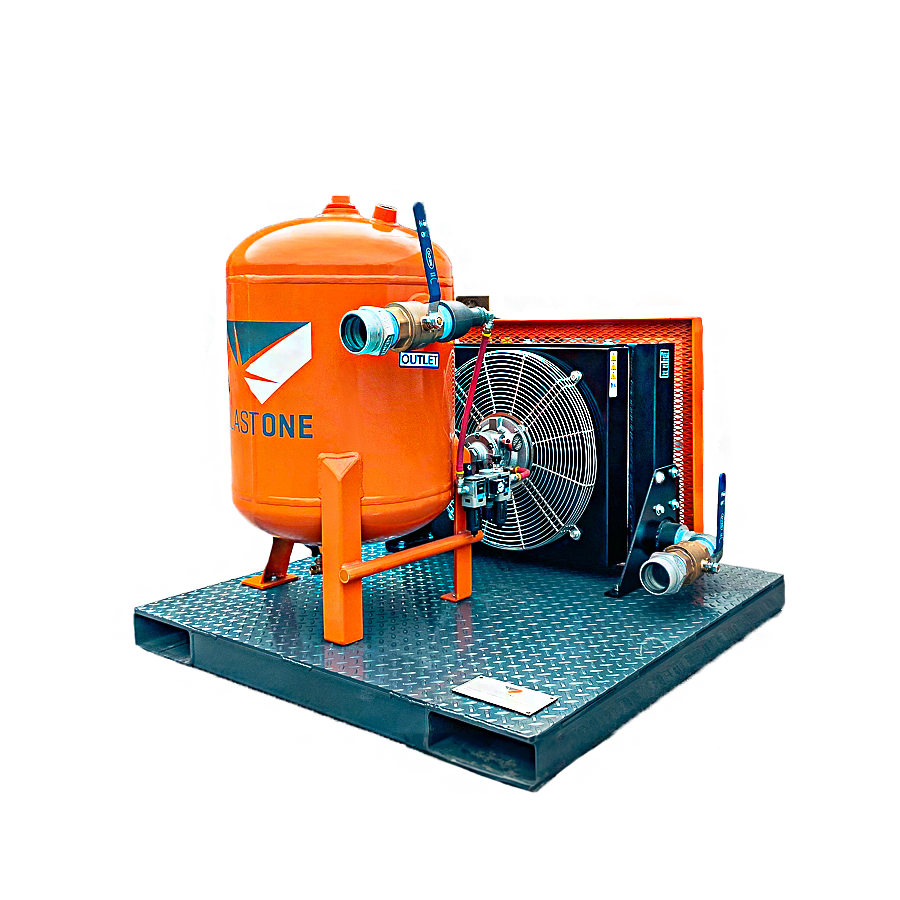

Enhance your blasting operations with the Squat Aftercooler AirDryer System, a compact, industry-standard moisture removal solution designed to increase blasting speed by up to 15%. Leveraging an Aftercooler design for optimum cooling, this system effectively removes moisture, saving on abrasive costs, and comes in sizes tailored to your compressor capacity. Rugged, portable, and equipped with a stainless steel demister pad for effective moisture removal, the Squat Aftercooler AirDryer System is built for high performance in high humidity and varied temperature environments.

- The Industry Standard AirDryer

- Squat Compact Design

- Uses Aftercooler design to cool the air for maximum moisture removal

- Pneumatic Fan motor

- Easy Maintenance

- Size based on the size of your compressor

- ACS250Squat – Rated to 250 cfm (good for 1x #6 blast nozzle)

- ACS400Squat – Rated to 400 cfm (good for 1x #7 blast nozzles

- ACS750Squat – Rated to 750 cfm (good for 2 blasters)

- ACS950Squat – Rated to 950 cfm (good for 2 blasters or occasionally 3)

- This unit will perform best when used in climates where the ambient temperature is above 50°F. Not recommended for use in climates that freeze. Recommend P-ACSD.

-

Elevate your production blasting with the Schmidt® AirPrep Deliquescent Desiccant Air Dryer, an industry-standard moisture removal system that uses Deliquescent tablets to absorb moisture for cooler, drier blasting. Experience enhanced efficiency, including 15% faster blasting, while saving on abrasive costs, all achieved through this rugged, skid-mounted system. Tailored to your needs with a range of sizes based on your compressor's CFM, this galvanized desiccant tank ensures easy maintenance and longevity, promising optimal performance even in high humidity environments and temperature fluctuations.

- The Premium Industry Standard Air Dryer

- Uses Deliquescent tablets to absorb moisture from the blasting air

- Pneumatic Fan motor with Easy Maintenance

- Galvanized Desiccant Tank lasts 5x longer then all competition

- Select size based on the CFM of your compressor

- Come fitted with 4-claw fittings

- 5 year warranty

- Genuine Products - Manufactured by Schmidt® / Axxiom Manufacturing

- ACSD250 / ADS250, ACSD400 / ADS400 / ACSD400P / ACSD750 / ADS750, ACSD950 / ADS950, ACSD1200 / ADS1200, ACSD1600 / ADS1600

-

Maximize your blasting efficiency with Schmidt® AirPrep™ Aftercooler Moisture Removal Systems, engineered for superior performance even in high humidity environments or critical applications. Utilizing an over-sized radiator for optimal flow and cooling, this rugged system features a stainless steel coalescing demister pad, ensuring non-restrictive, effective moisture removal, and requiring no replacement elements. Built to last, the Schmidt® AirPrep™ enhances production by allowing up to 15% faster blasting and reducing abrasive expenditure, thanks to its negligible pressure loss design and efficient moisture elimination.

FOR RENTAL OR PURCHASE

- The Premium Industry Standard AirDryer

- Uses Aftercooler design to cool the air for maximum moisture removal

- Removes 90% of the moisture in the blasting air

- Pneumatic Fan motor mean you don't need electricity to run this onsite

- Size based on the size of your compressor

- Suitable for warm weather or indoor use

- Genuine Schmidt® Products - Guaranteed to Perform!

-

ACS400ACReplacement radiator for ACS400SQUAT BlastOne Air Dryer.

- Efficient cooling with 400 CFM capacity

- Pneumatic Fan for rapid heat dissipation

- Durable construction for long-term reliability

- Compatible with various pneumatic tools

- 2" fitting

ACS400ACReplacement radiator for ACS400SQUAT BlastOne Air Dryer.- Efficient cooling with 400 CFM capacity

- Pneumatic Fan for rapid heat dissipation

- Durable construction for long-term reliability

- Compatible with various pneumatic tools

- 2" fitting

-

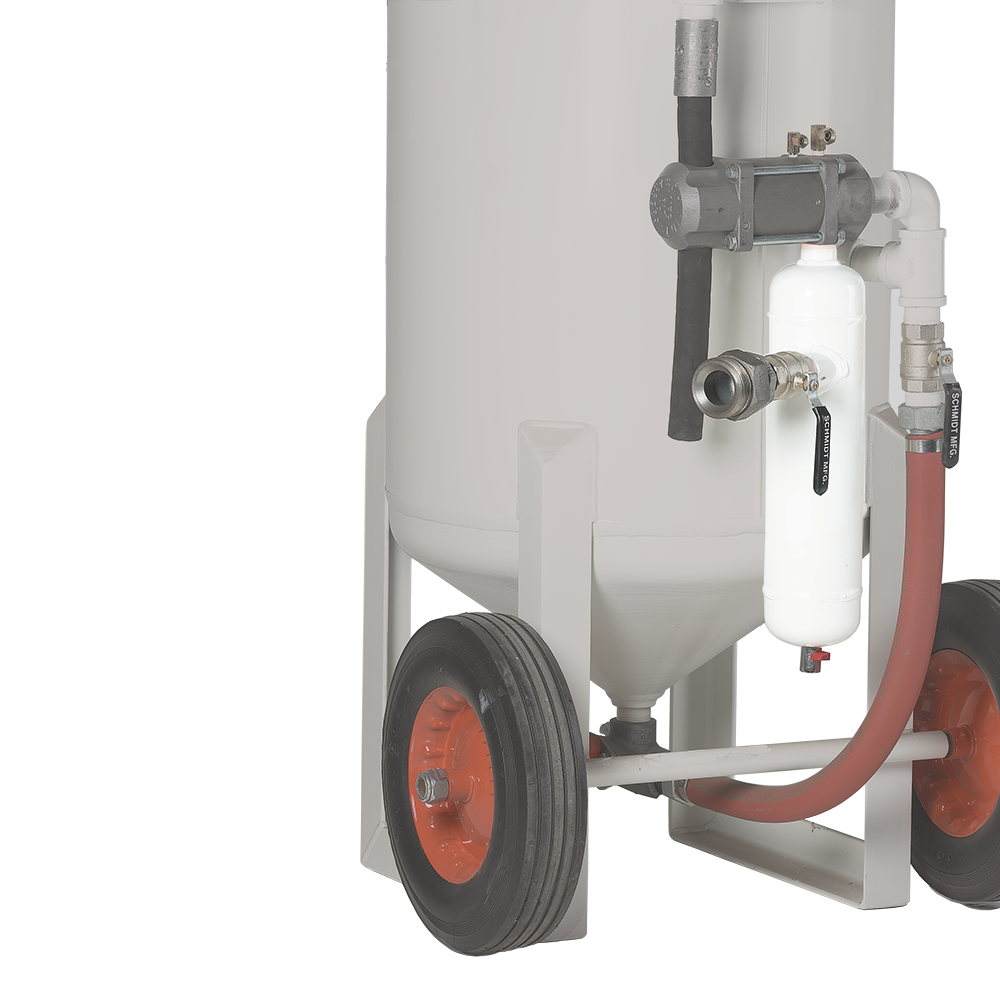

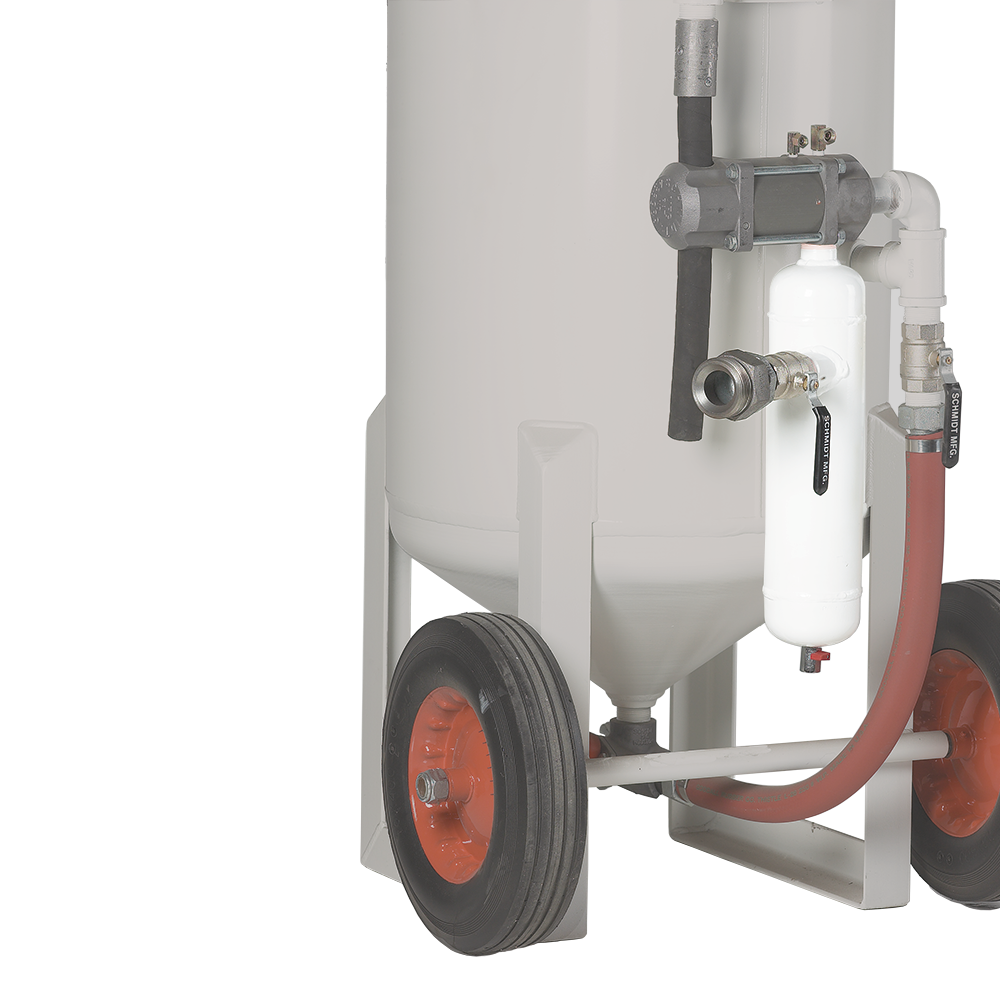

The Inlet Airline Moisture Separator, designed specifically for abrasive blasting, provides final stage moisture droplet removal before air enters the blast machine, ensuring minimal pressure loss for peak blasting productivity. Utilizing an elementless design with a tangential flow, and an internal stainless steel coalescer, it handles large air volumes without efficiency loss. This system can be sized at 250cfm or 400cfm based on your blast nozzle and compressor size, and though it requires separate order of inlet fitting or ball valve, it promises improved blasting performance with drier air.

- Installed at blast machine inlet for final stage moisture droplet removal before air enters blast machine

- Tangential flow and elementless design

- Minimal pressure loss for peak blasting productivity

- Requires 1/4' ball valve for drainage - part no. FVBL006MF or APF3004

- Optional autodrain accessory available

- Male threaded inlet and outlet ports

- Inlet fitting or ball valve not supplied - order separately

- Specify Size - 250cfm or 400cfm, based on the size of your blast nozzle and compressor

- Includes internal stainless steel coalescer

-

Built by Schmidt®, these moisture separators are available in multiple versions as follows:

- Size

- 800 or 1600 CFM capacity

- Configuration

- Stationary or Portable (with handle, axle & wheels)

- Fittings

- Built with 2" NPT ports on both Inlet and Outlet, these can be equipped with your choice of Spud or 4-claw fittings, ball valves, splitters, etc.

- Size

-

ACS400AC12VRated 284 CFM capacity and 375 CFM Max capacity, this stand-mounted radiator is an economical aftercooler option, when budget or space do not allow the more efficient Squat Aftercooler or Deliquescent Air Dryer. It comes with a 12 volt battery lead, for your convenient connection to any 12 volt vehicle battery.ACS400AC12VRated 284 CFM capacity and 375 CFM Max capacity, this stand-mounted radiator is an economical aftercooler option, when budget or space do not allow the more efficient Squat Aftercooler or Deliquescent Air Dryer. It comes with a 12 volt battery lead, for your convenient connection to any 12 volt vehicle battery.

-

ACSDR50

- Suits the AirPrep ADS Series

- Replacement deliquescent tablets to refill an air dryer.

- Also referred to as desiccant tablets

- Hard, white tablets can absorb up to 4 times their own weight in water!

- Comes in 50 lb bags, 40 bags per pallet

- Dry-O-Lite® deliquescent tablets are made by Van Air Systems. MPN: 33-0311

ACSDR50- Suits the AirPrep ADS Series

- Replacement deliquescent tablets to refill an air dryer.

- Also referred to as desiccant tablets

- Hard, white tablets can absorb up to 4 times their own weight in water!

- Comes in 50 lb bags, 40 bags per pallet

- Dry-O-Lite® deliquescent tablets are made by Van Air Systems. MPN: 33-0311

-

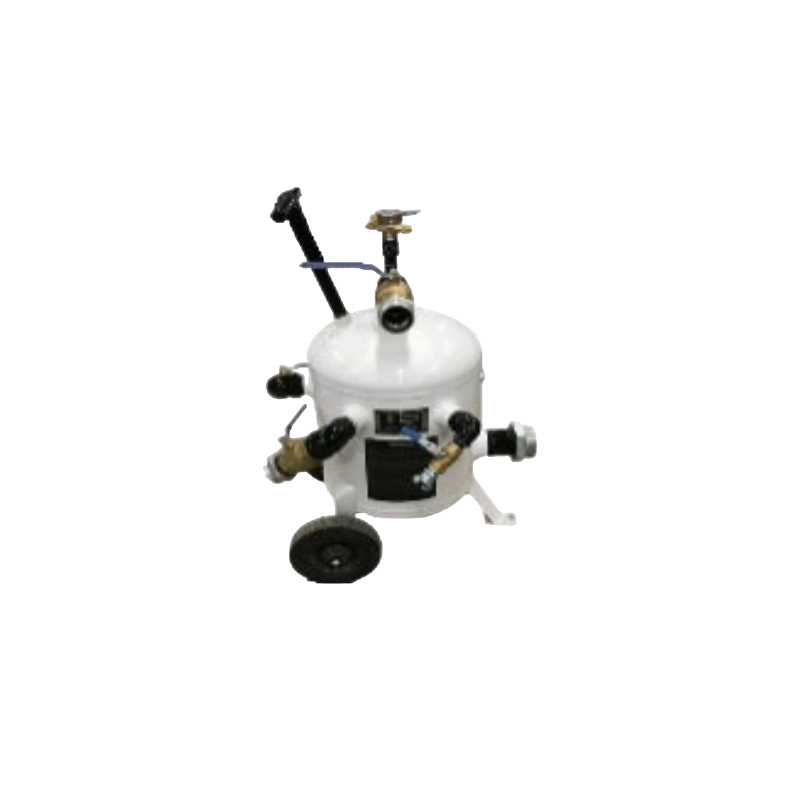

ASEPPIGWhen the primary air dryer is located at a distance from the blast pot, secondary moisture removal becomes critical. The Sponge-Jet moisture separation tank is ideal for this application. Includes the following:

- Handle for easy portability

- Spud / BOSS blast hose fitting

- Multiple sized ball valves & couplings

ASEPPIGWhen the primary air dryer is located at a distance from the blast pot, secondary moisture removal becomes critical. The Sponge-Jet moisture separation tank is ideal for this application. Includes the following:- Handle for easy portability

- Spud / BOSS blast hose fitting

- Multiple sized ball valves & couplings

-

ACFRL06

- 3-piece filter/regulator/lubricator

- Compact body design

- 2-piece modular joiner set

- Snap-lock knob prevents accidental change of set pressure

- Easy-to-read pressure gauge included

- Maximum supply pressure - 150psi

- Wall mount brackets included

- Manufactured by Wilkerson®

ACFRL06- 3-piece filter/regulator/lubricator

- Compact body design

- 2-piece modular joiner set

- Snap-lock knob prevents accidental change of set pressure

- Easy-to-read pressure gauge included

- Maximum supply pressure - 150psi

- Wall mount brackets included

- Manufactured by Wilkerson®

-

ACFRL13400MPBoost your 400cfm Schmidt® AirPrep™ Air Dryer's efficiency with the 1/2" Filter/Regulator/Lubricator (SKU: ACFRL13400MP) by Master Pneumatic®. This FRL unit combines MP165 filter/regulator and MP167 lubricator for optimal performance.

- 1/2" Filter/Regulator/Lubricator designed exclusively for Schmidt® AirPrep™ 400cfm Air Dryers.

- Features both MP165 filter/regulator and MP167 lubricator for a comprehensive air system care.

- Manufactured by the esteemed Master Pneumatic® brand.

- Master Pneumatic® specializes in a wide range of FRL combinations, catering to various applications.

- A crucial addition for maximizing the efficiency and lifespan of your air dryer systems.

ACFRL13400MPBoost your 400cfm Schmidt® AirPrep™ Air Dryer's efficiency with the 1/2" Filter/Regulator/Lubricator (SKU: ACFRL13400MP) by Master Pneumatic®. This FRL unit combines MP165 filter/regulator and MP167 lubricator for optimal performance.- 1/2" Filter/Regulator/Lubricator designed exclusively for Schmidt® AirPrep™ 400cfm Air Dryers.

- Features both MP165 filter/regulator and MP167 lubricator for a comprehensive air system care.

- Manufactured by the esteemed Master Pneumatic® brand.

- Master Pneumatic® specializes in a wide range of FRL combinations, catering to various applications.

- A crucial addition for maximizing the efficiency and lifespan of your air dryer systems.

-

ACFRL131600MPExperience enhanced air dryer performance with the 1/2" Filter/Regulator/Lubricator (SKU: ACFRL131600MP) by Master Pneumatic®. Perfectly tailored for 750cfm - 1,600cfm Schmidt® AirPrep™ systems, including both MP160 filter/regulator and MP125 lubricator.

- 1/2" Filter/Regulator/Lubricator tailored for Schmidt® AirPrep™ systems ranging from 750cfm to 1,600cfm.

- Incorporates both MP160 filter/regulator and MP125 lubricator for comprehensive care.

- Quality assurance from the renowned Master Pneumatic® brand.

- Master Pneumatic® offers an extensive range of FRL combinations to cater to diverse applications.

- An essential add-on for maximizing the longevity and efficiency of your air systems.

ACFRL131600MPExperience enhanced air dryer performance with the 1/2" Filter/Regulator/Lubricator (SKU: ACFRL131600MP) by Master Pneumatic®. Perfectly tailored for 750cfm - 1,600cfm Schmidt® AirPrep™ systems, including both MP160 filter/regulator and MP125 lubricator.- 1/2" Filter/Regulator/Lubricator tailored for Schmidt® AirPrep™ systems ranging from 750cfm to 1,600cfm.

- Incorporates both MP160 filter/regulator and MP125 lubricator for comprehensive care.

- Quality assurance from the renowned Master Pneumatic® brand.

- Master Pneumatic® offers an extensive range of FRL combinations to cater to diverse applications.

- An essential add-on for maximizing the longevity and efficiency of your air systems.

-

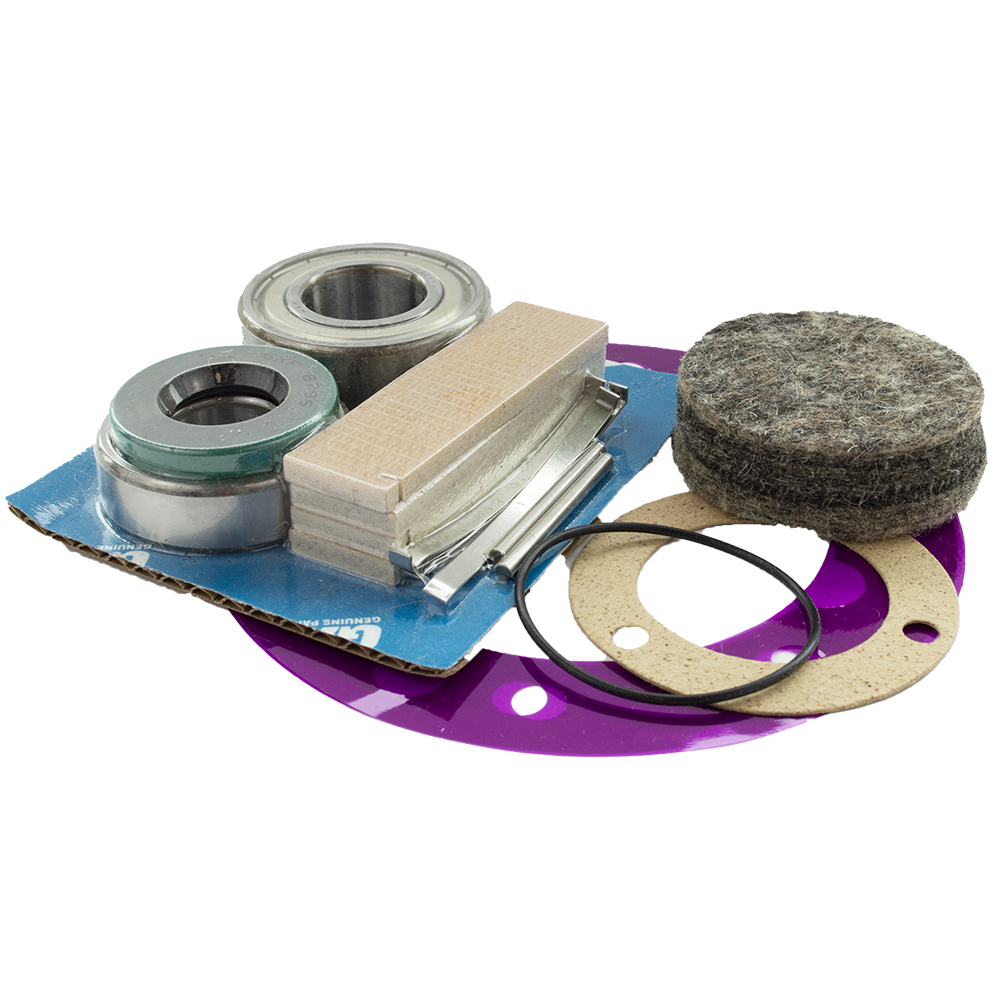

AC130009099*Enhance the life of your AirPrep Air Motor AC130009003 6AM (ACS950) with the comprehensive Repair Kit (SKU: AC130009099*). Complete with 4 vanes, seals, and bearings, it’s everything you need for a thorough motor refurbishment.

- Exclusively designed for AirPrep Air Motor AC130009003 6AM (ACS950).

- Comprehensive kit includes 4 vanes, seals, and bearings.

- High-quality components for effective refurbishment.

- Ensures prolonged motor lifespan and optimal operation.

- Sold as a complete kit for user convenience.

AC130009099*Enhance the life of your AirPrep Air Motor AC130009003 6AM (ACS950) with the comprehensive Repair Kit (SKU: AC130009099*). Complete with 4 vanes, seals, and bearings, it’s everything you need for a thorough motor refurbishment.- Exclusively designed for AirPrep Air Motor AC130009003 6AM (ACS950).

- Comprehensive kit includes 4 vanes, seals, and bearings.

- High-quality components for effective refurbishment.

- Ensures prolonged motor lifespan and optimal operation.

- Sold as a complete kit for user convenience.

-

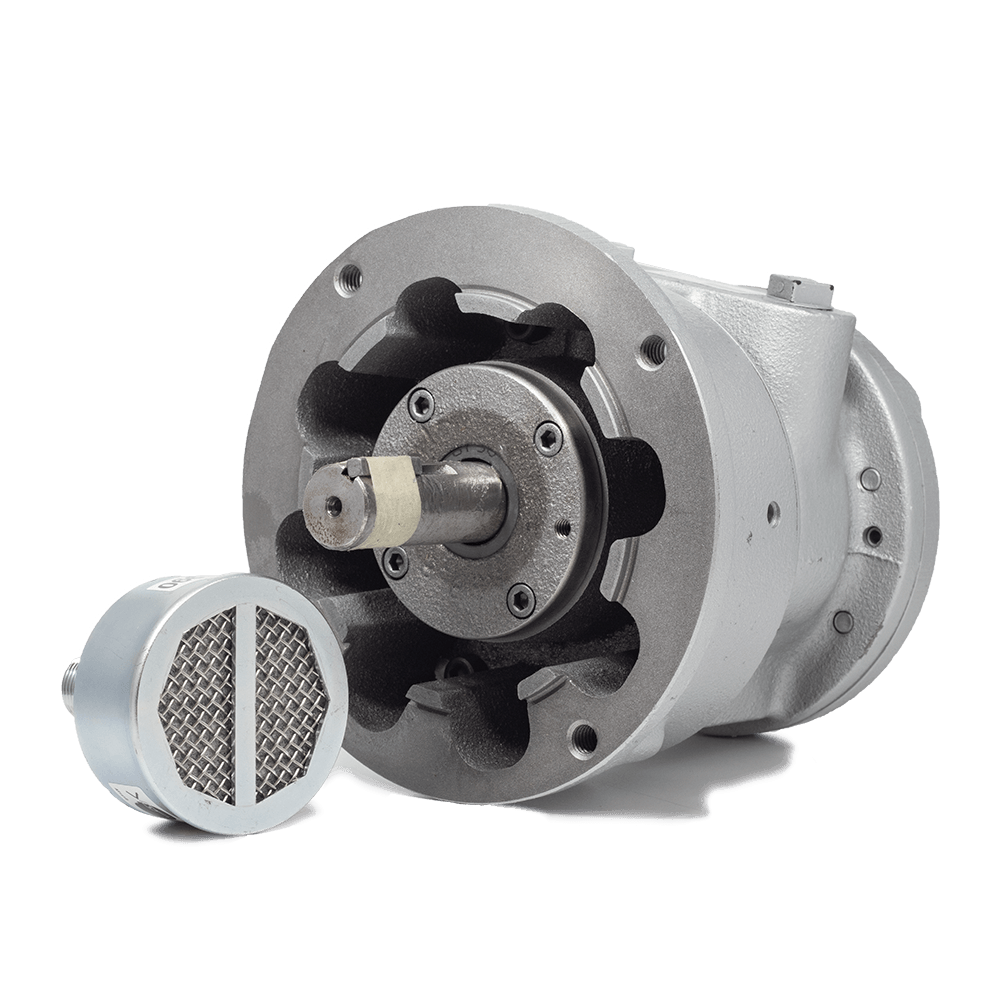

AC130016003Optimize your Schmidt® Air Dryers ACS1600 ADS1600 with the Air Motor for ACS1600 ADS1600 AirPrep™ system (SKU: AC130016003). Featuring 8 pneumatic vanes, it powers the aftercooler fan with precision. Available individually.

- Exclusively crafted for Schmidt® Air Dryers ACS1600 and ADS1600 - 1600cfm.

- Pneumatically operated motor with 8 efficient vanes.

- Reversible feature for prolonged motor lifespan.

- Sturdy design with a net weight of 28 lbs.

- Sold individually to cater to your specific needs.

AC130016003Optimize your Schmidt® Air Dryers ACS1600 ADS1600 with the Air Motor for ACS1600 ADS1600 AirPrep™ system (SKU: AC130016003). Featuring 8 pneumatic vanes, it powers the aftercooler fan with precision. Available individually.- Exclusively crafted for Schmidt® Air Dryers ACS1600 and ADS1600 - 1600cfm.

- Pneumatically operated motor with 8 efficient vanes.

- Reversible feature for prolonged motor lifespan.

- Sturdy design with a net weight of 28 lbs.

- Sold individually to cater to your specific needs.

-

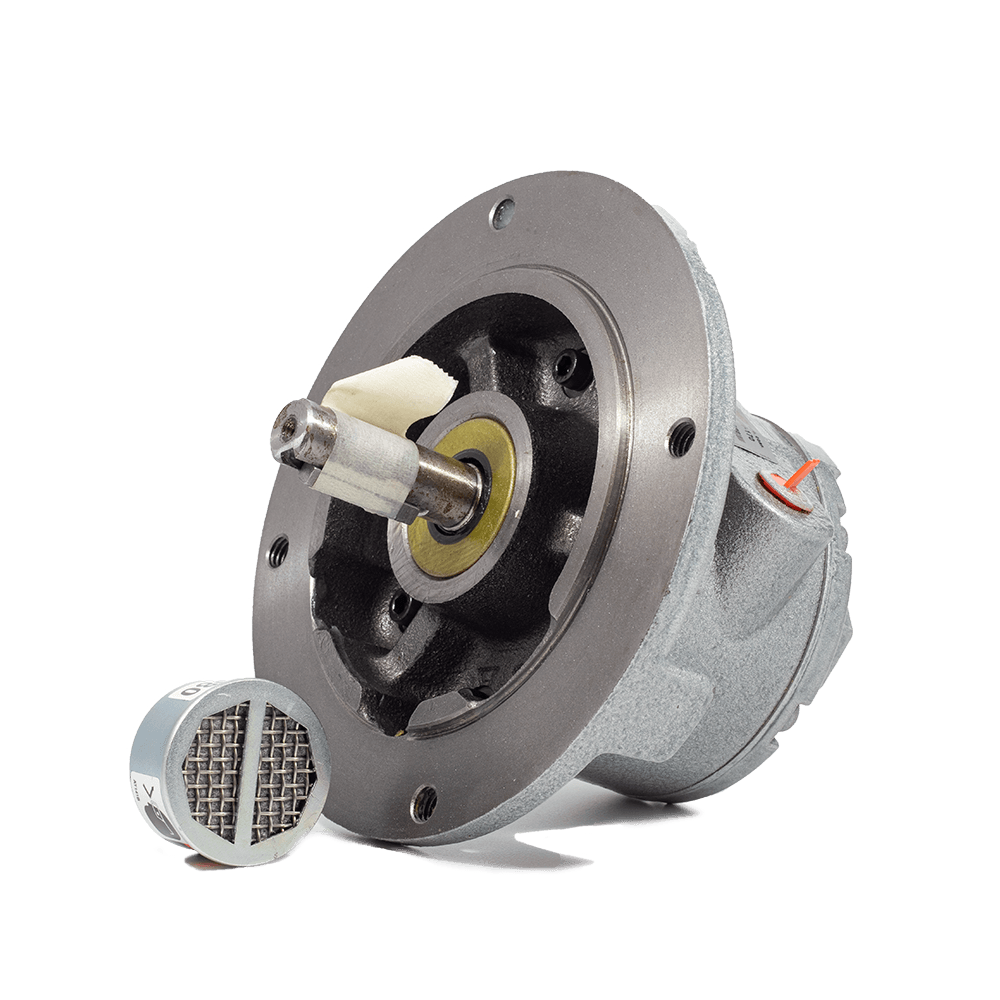

AC130004003The Schmidt AirPrep™ Air Motor (SKU: AC130004003) is designed specifically for Schmidt® Air Dryers ACS and ADS. This 4-vaned pneumatic motor powers the aftercooler fan, ensuring optimal performance. Sold individually.

- Specifically designed for Schmidt® Air Dryers ACS and ADS (250, 400, 750cfm).

- Drives the aftercooler fan with 4 pneumatic vanes.

- Reversible function for enhanced durability.

- Net weight of 12 lbs.

- Sold individually for your convenience.

AC130004003The Schmidt AirPrep™ Air Motor (SKU: AC130004003) is designed specifically for Schmidt® Air Dryers ACS and ADS. This 4-vaned pneumatic motor powers the aftercooler fan, ensuring optimal performance. Sold individually.- Specifically designed for Schmidt® Air Dryers ACS and ADS (250, 400, 750cfm).

- Drives the aftercooler fan with 4 pneumatic vanes.

- Reversible function for enhanced durability.

- Net weight of 12 lbs.

- Sold individually for your convenience.

My Account

My Account

Aftercoolers

Aftercoolers Deliquescent Dryers

Deliquescent Dryers Moisture Separators

Moisture Separators Parts & Consumables - Air Dryers

Parts & Consumables - Air Dryers