Moisture Separators

Our moisture separators come equipped with features such as high-capacity handling, portable designs, and elementless operation for minimal pressure loss. Each separator is crafted to provide superior moisture removal, ensuring your equipment operates efficiently and without interruption.

Whether you need a portable unit for on-site flexibility or a stationary system for a permanent setup, we offer solutions that cater to your specific needs. If you need further assistance or can’t find the exact product you’re looking for, please contact BlastOne or use the live chat feature in the bottom right of your browser window.

Showing all 3 results

-

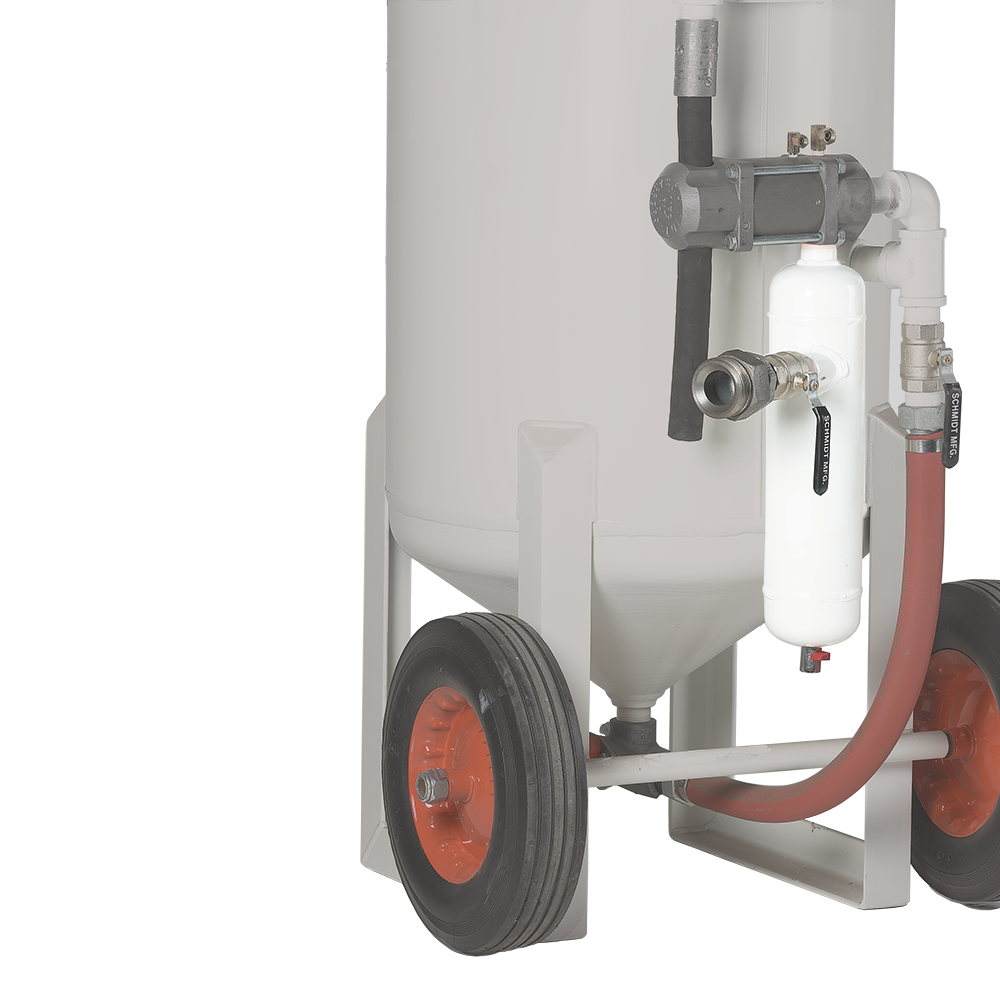

The Schmidt Inline Moisture Separator mounts directly at the blast pot inlet to provide effective secondary moisture removal in abrasive blasting systems. Designed to catch residual moisture missed by primary dryers, this compact unit helps protect metering valves and control components from condensation damage.

Selected Features:

- Installed at blast machine inlet for final stage moisture droplet removal before air enters blast machine

- Performs secondary moisture removal to enhance blasting system reliability

- Not intended for primary moisture removal—should be used in conjunction with an air dryer or aftercooler

- Original Equipment Schmidt design, painted

-

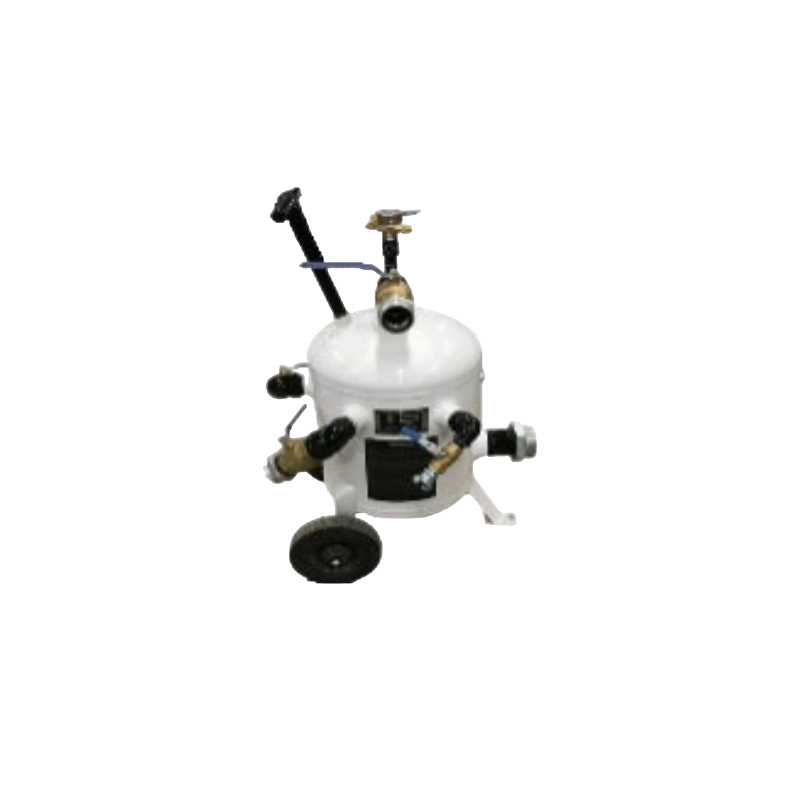

The Schmidt Moisture Separator Tank is engineered to remove moisture from compressed air systems, improving performance in abrasive blasting operations. Utilizing expansion-based separation, this unit is ideal for environments where moderate moisture control is sufficient, offering a cost-effective solution without the need for more complex drying systems.

- Efficient moisture removal through expansion-based separation

- Enhances abrasive flow and reduces contamination of controls

- Suitable for less humid environments, or alternatively, as a final moisture trap inline with the blast pot, when the air dryer is a long distance from the pot.

- Available in 800 or 1600 CFM capacities

- Can be configured as stationary (stand mounted), or as portable with handle, axle, and wheels

- SKU's are as follows:

- 800 CFM, Stand mount: AFMSH800

- 800 CFM, Portable: AFMSH800P

- 1600 CFM, Stand mount: AFMSH1600

- 1600 CFM, Portable: AFMSH1600P

-

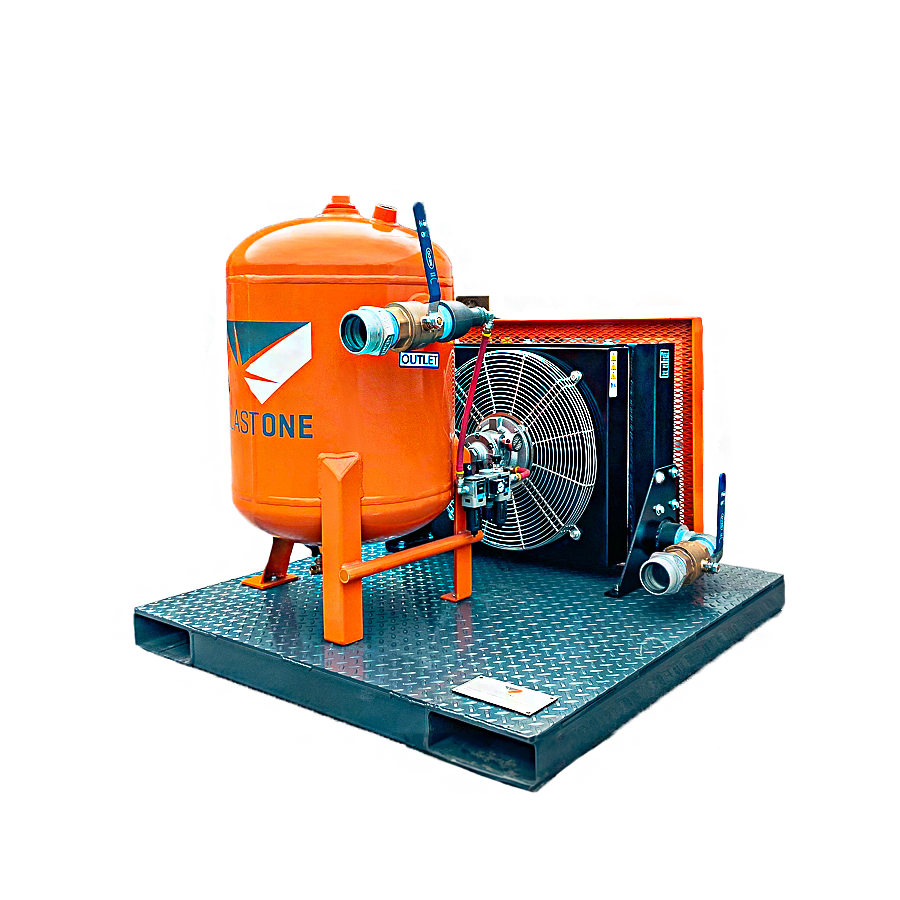

ASEPPIGWhen the primary air dryer is located at a distance from the blast pot, secondary moisture removal becomes critical. The Sponge-Jet moisture separation tank is ideal for this application. Includes the following:

- Handle for easy portability

- Spud / BOSS blast hose fitting

- Multiple sized ball valves & couplings

ASEPPIGWhen the primary air dryer is located at a distance from the blast pot, secondary moisture removal becomes critical. The Sponge-Jet moisture separation tank is ideal for this application. Includes the following:- Handle for easy portability

- Spud / BOSS blast hose fitting

- Multiple sized ball valves & couplings

Moisture separators are essential for ensuring optimal performance and longevity of abrasive blasting equipment. Our selection includes high-capacity portable separators, inlet airline separators, and Sponge-Jet moisture separator tanks. These units effectively remove moisture from compressed air systems, preventing clogs and ensuring smooth, efficient operation.

Available in various configurations and sizes, our moisture separators are designed to meet the demanding needs of industrial applications, providing reliable moisture control to keep your blasting operations running at peak efficiency.

My Account

My Account

Air Dryers

Air Dryers Aftercoolers

Aftercoolers Deliquescent Dryers

Deliquescent Dryers Parts & Consumables - Air Dryers

Parts & Consumables - Air Dryers