Blast Machine Accessories

Showing all 2 results

-

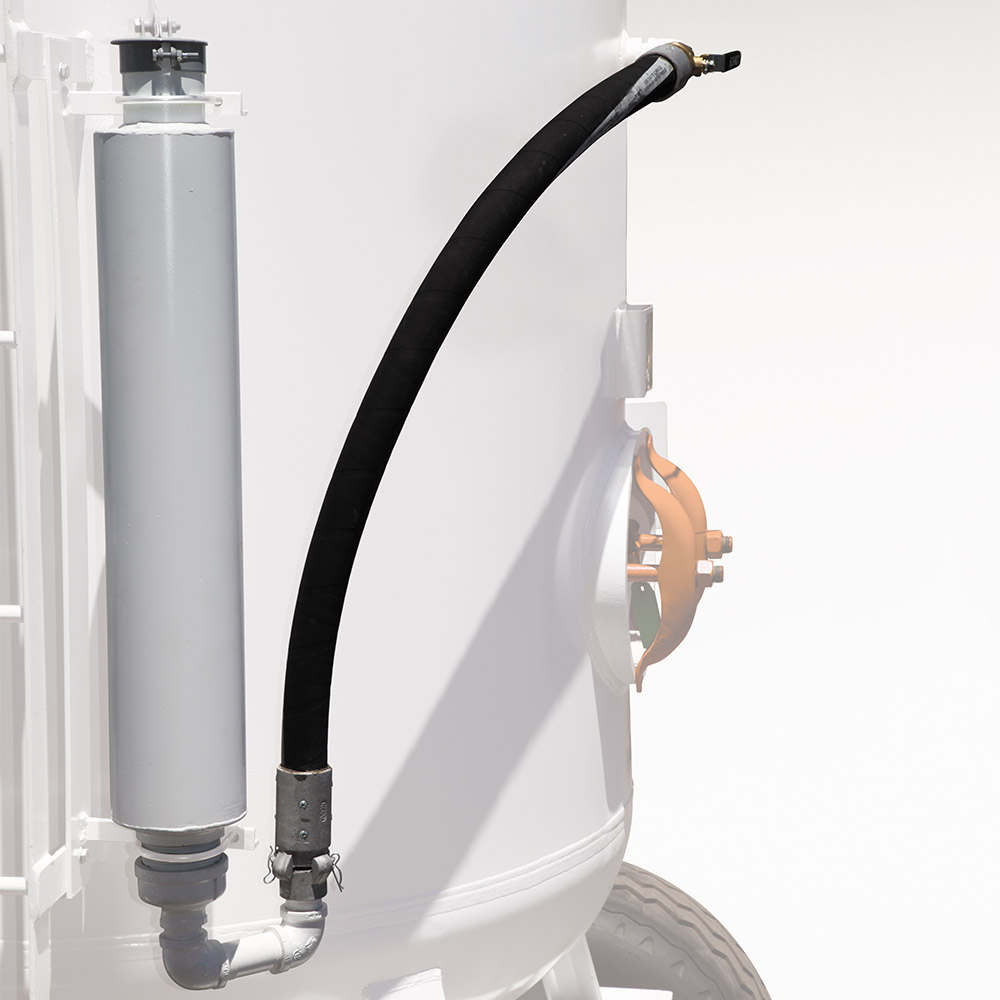

DMMEM100KITThe Controlled Expansion Nozzle (CEN) Muffler Kit by Axxiom / Schmidt for Mega Pots significantly improves safety as well as reducing blowdown noise.

- Using a CEN muffler removes the risk of freeze-up at the vent. Without this muffler, dangerous pressure can remain in the pot due to vent freeze-up. Injury or death can result to an operator who removes the abrasive loading cover under pressure.

- In addition, noise levels during blowdown without a CEN can exceed 140db. With the CEN, the noise is reduced to 92db.

- The kit includes a 3" NPT thread connection. As mounting brackets are not included in the kit (due to the restriction on welding on a pressure vessel after certification), customer will need to decide best place for mounting, possibly using the ladder. BlastOne technicians are available - contact us if any questions.

DMMEM100KITThe Controlled Expansion Nozzle (CEN) Muffler Kit by Axxiom / Schmidt for Mega Pots significantly improves safety as well as reducing blowdown noise.- Using a CEN muffler removes the risk of freeze-up at the vent. Without this muffler, dangerous pressure can remain in the pot due to vent freeze-up. Injury or death can result to an operator who removes the abrasive loading cover under pressure.

- In addition, noise levels during blowdown without a CEN can exceed 140db. With the CEN, the noise is reduced to 92db.

- The kit includes a 3" NPT thread connection. As mounting brackets are not included in the kit (due to the restriction on welding on a pressure vessel after certification), customer will need to decide best place for mounting, possibly using the ladder. BlastOne technicians are available - contact us if any questions.

-

The Air Pressure Gage is a crucial tool for monitoring air pressure in your blast equipment, ensuring optimal performance and safety. This general-purpose gage is sold individually and designed not to exceed the manufacturer's recommendation. Secure your blasting operations with this reliable Air Pressure Gage for precise and consistent air pressure tracking.

- General purpose air pressure gages for monitoring of air pressure

- Do not exceed manufacturers recommendation for blast equipment

- Sold Individually

A top priority for corrosion control contractors is knowing how to dry air for sandblasting. It is essential that you remove the moisture from your compressed air for efficient blasting. Moisture can cause your abrasive to clog, slow down your blasting speed and even cause your freshly blasted surface to rust.

Cool, dry air exits the air dryer and is connected to the hose for your blast machine. The result keeps moisture from the blasting surface which minimizes any potential rusting before the protective coating is applied.

Air dryers are used to dry the air between the compressor and the blasting or spraying equipment. Warm, moist air from the compressor enters the air prep dryer and travels into a radiator where the air is cooled. As the temperature drops from warm to cool, it then enters the expansion tank which causes the water to drop to the bottom. Cool, dry air exits the air dryer and is connected to the hose for your blast machine. The result keeps moisture from the blasting surface which minimizes any potential rusting before the protective coating is applied.

My Account

My Account