Blast Equipment

Showing 46–60 of 76 results

-

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

VCBRS35FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Abrasive holding capacity of 3.5 cu ft

- Blasting rate up to 40 ft2 per hour

- Compressed Air Requirement 750 cfm

- Includes fork pockets

- Can be wheel mounted for increased jobsite maneuverability

- Recirculating full size blast & recovery unit

- 100% compressed air driven - no electricity required

-

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Blasting rate up to 20 ft2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

VCBRSMP46FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty- Blasting rate up to 20 ft2 per hour. Due to this low production rate, this unit is intended for specialty applications, such as spot-work in dust-sensitive areas.

- Utilizes the TeraValve XL abrasive metering valve

- Compressed Air Requirement is only 185 cfm

- Has wheels and fork pockets for easy portability by hand, or by forklift.

- 100% compressed air powered - no electricity required

- Various workheads are available for flat surfaces, inside corners, outside corners, etc. - enquire for details.

- Genuine Products - Manufactured by Schmidt / Axxiom Manufacturing

-

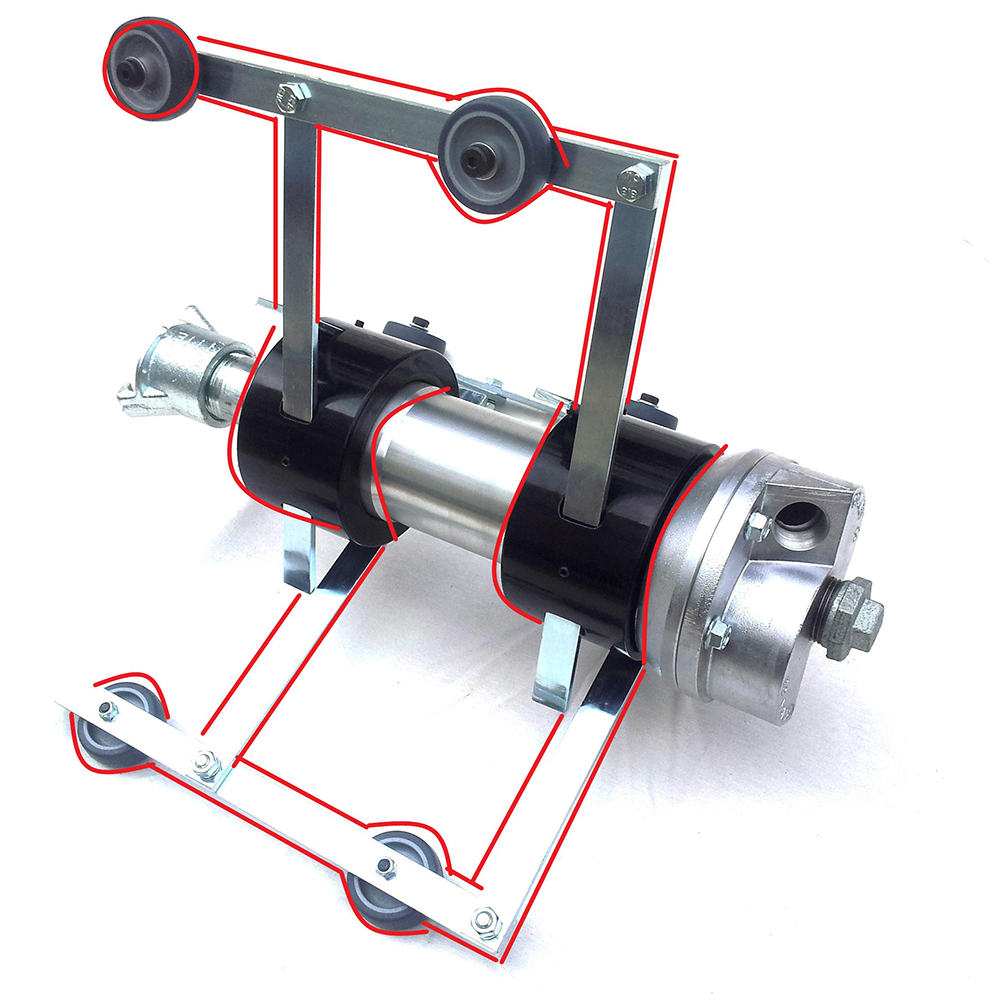

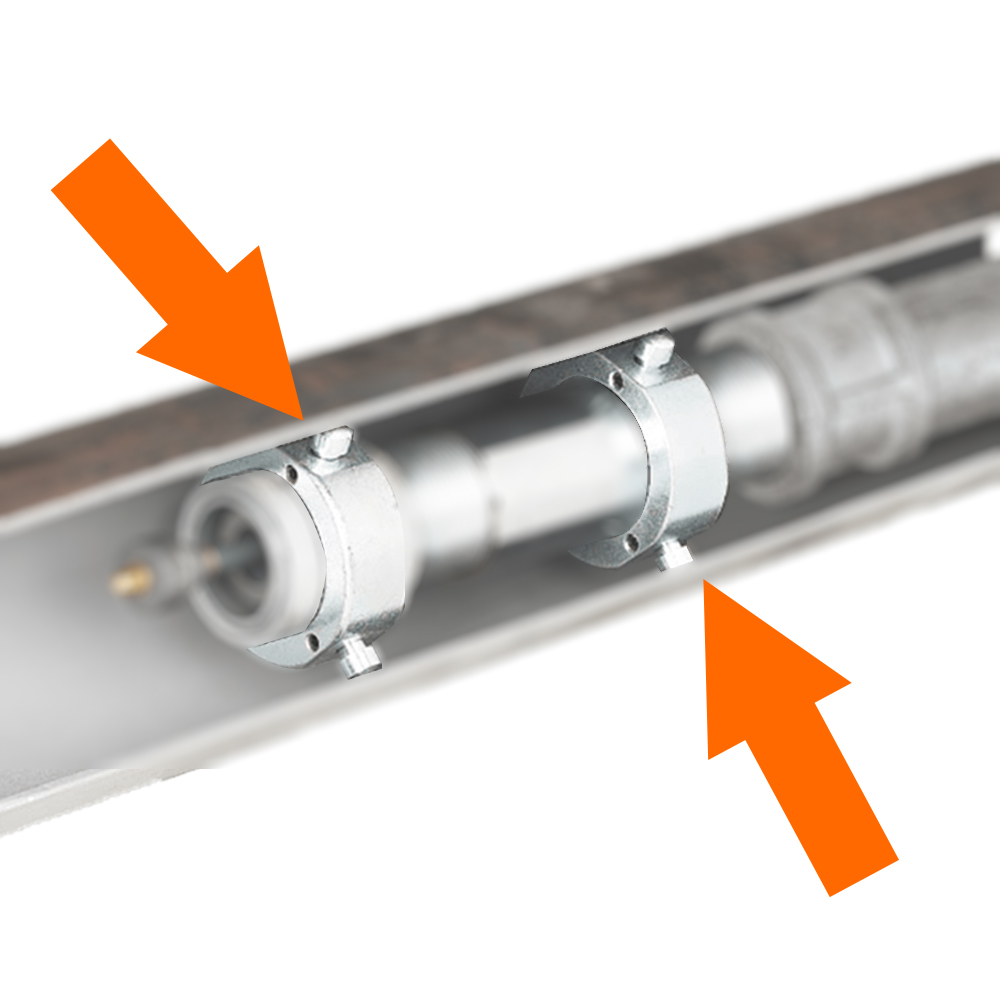

IPC1200

- Fits to IPC1000 as one assembly (outlined in red in image)

- Suitable for pipes between 8" and 36" in diameter

- Consists of 2 collars, 3 two-wheel roller bars and 4 sets of centering legs (6 legs per set)

IPC1200- Fits to IPC1000 as one assembly (outlined in red in image)

- Suitable for pipes between 8" and 36" in diameter

- Consists of 2 collars, 3 two-wheel roller bars and 4 sets of centering legs (6 legs per set)

-

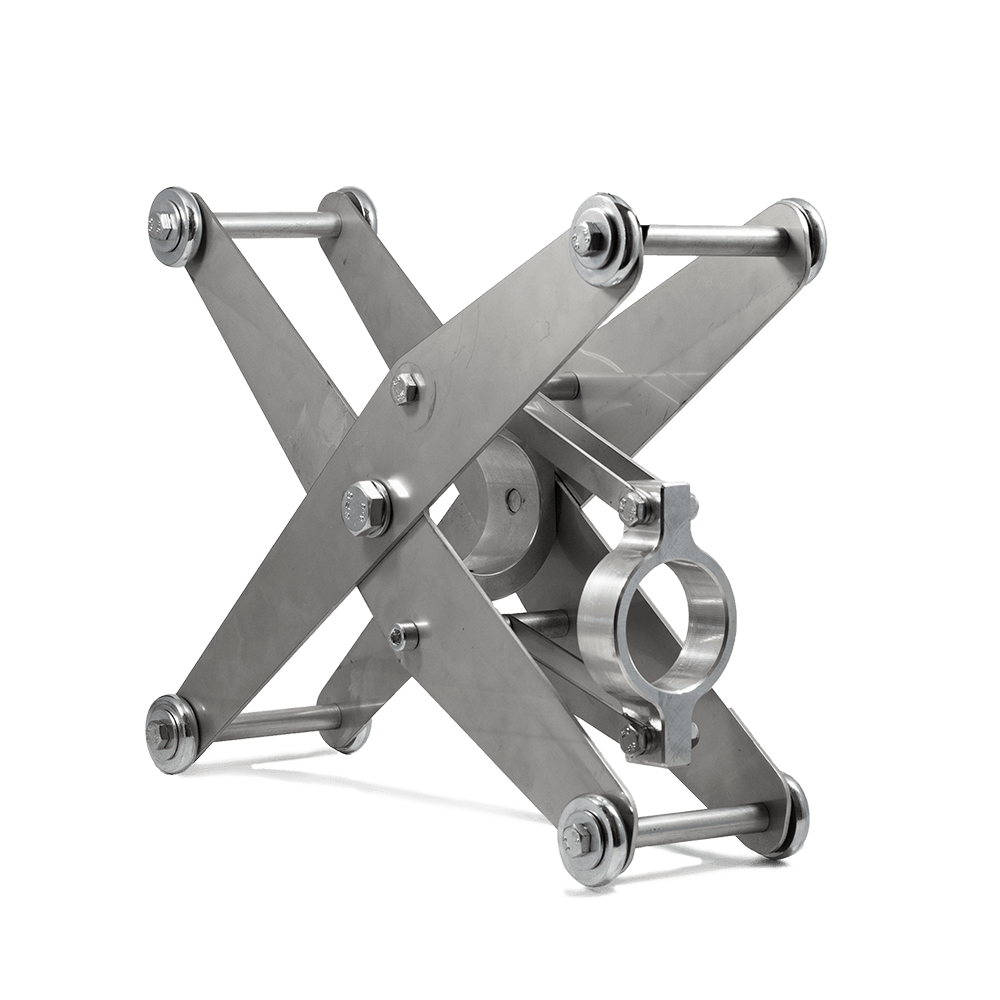

IPC4200

- Suits IPC4000 and IPC4500 ConeBlast Pipe Blasting System

- Ideal for blasting pipes between 5'' - 12'' internal diameter

- 'Scissor Type' Centering Carriage

- Sold Individually

IPC4200- Suits IPC4000 and IPC4500 ConeBlast Pipe Blasting System

- Ideal for blasting pipes between 5'' - 12'' internal diameter

- 'Scissor Type' Centering Carriage

- Sold Individually

-

HT3202404T

-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- 8" cutting width

- Easy to use, maintain and maneuver

- Precise screw type scaling head adjustment

- Angled dust port allows connection of industrial dust collector giving virtually dust free performance

- Supplied complete & ready to work with cutter head

- Updated version with improved electrics and start switch

-

HT3202404T-

-

- FREE Shipping

- 30 Day Money-Back Guarantee | Free Returns

- 8" cutting width

- Easy to use, maintain and maneuver

- Precise screw type scaling head adjustment

- Angled dust port allows connection of industrial dust collector giving virtually dust free performance

- Supplied complete & ready to work with cutter head

- Updated version with improved electrics and start switch

-

-

-

CAPSG02641Designed for abrasive blasting applications with limited air supply, the Suction Blaster is intended for small projects / touch-up work, etc. This complete setup (compressor and abrasive not included) can blast with as little as 12 cfm, using the included #5 nozzle and 1/8" air jet. The package includes the following:

- Light-duty, portable hopper with top screen

- SG-300 blast gun with #5 nozzle and 1/8" air jet

- 10' air hose, 1/2" ID

- 10' blast hose, 1/2" ID

- Package as shown MPN: 02641

CAPSG02641Designed for abrasive blasting applications with limited air supply, the Suction Blaster is intended for small projects / touch-up work, etc. This complete setup (compressor and abrasive not included) can blast with as little as 12 cfm, using the included #5 nozzle and 1/8" air jet. The package includes the following:- Light-duty, portable hopper with top screen

- SG-300 blast gun with #5 nozzle and 1/8" air jet

- 10' air hose, 1/2" ID

- 10' blast hose, 1/2" ID

- Package as shown MPN: 02641

-

BMS1001TVFREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Manufacturer Warranty

- 10 cu ft Schmidt® Blast pot

- Excellent for a blastroom application with 1-2 blasters

- Single outlet Thompson® Valve II abrasive metering valve, Dual available

- Abrasive capacity

- Garnet 1500 lbs

- Steel Grit 2450 lbs

- Comes with pneumatic deadman handle and 55ft of control hose, Electric available

BMS1001TVFREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Manufacturer Warranty- 10 cu ft Schmidt® Blast pot

- Excellent for a blastroom application with 1-2 blasters

- Single outlet Thompson® Valve II abrasive metering valve, Dual available

- Abrasive capacity

- Garnet 1500 lbs

- Steel Grit 2450 lbs

- Comes with pneumatic deadman handle and 55ft of control hose, Electric available

-

DM2152ACRK

- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

DM2152ACRK- Pneumatic Complete Retrofit kit includes:

- Triple-line coupled remote control hose

- Control hose connections for air supply

- Auto air valve and Thompson Valve II metering valve

- Pneumatic push-pull abrasive on-off switch

- Response deadman handle

-

- Compatible with a wide range of blast pots

- Digital display of actual blasting time for individual blast outlets

- Allows you to determine productivity, production rates, assisting project costings, job estimates and scheduling maintenance for common wear items

- System available to run off pneumatic and electric deadman controls

- Triggered instantly by the deadman signal, so you get actual blasting hours

- Options available for single and multiple outlets.

-

SBMGP

- Pre-engineered to minimize costs and ensure quick set up

- Typical max part size (to be blasted): 5’ x 3’ x 8’ (W x H x L)

- Blasting chamber with set of double-doors

- Dust tight, high-powered LED lights in ceiling

- Shovel-in hopper, elevator and air classifier for basic abrasive recovery/recycling

- Includes abrasive storage hopper and high-performance sandblasting machine

- Separate personnel side access door (optional)

SBMGP- Pre-engineered to minimize costs and ensure quick set up

- Typical max part size (to be blasted): 5’ x 3’ x 8’ (W x H x L)

- Blasting chamber with set of double-doors

- Dust tight, high-powered LED lights in ceiling

- Shovel-in hopper, elevator and air classifier for basic abrasive recovery/recycling

- Includes abrasive storage hopper and high-performance sandblasting machine

- Separate personnel side access door (optional)

-

SBMGI

- High quality, acoustically insulated steel sandwich panel construction

- Ideal for consistent blasting production (1 operator, 20-40 hrs/week)

- Various material handling options: product carts, forklift loading, manual handling

- Partial or Full-floor abrasive recovery system

- Airwash abrasive cleaner for grit recycling with vibrating screen for trash removal

- Reverse pulse cartridge dust collector

- Typical size ranging from:

- 10’ W x 10’ H x 10’ L (small)

- 22’ W x 22’ H x 100’ L (large)

SBMGI- High quality, acoustically insulated steel sandwich panel construction

- Ideal for consistent blasting production (1 operator, 20-40 hrs/week)

- Various material handling options: product carts, forklift loading, manual handling

- Partial or Full-floor abrasive recovery system

- Airwash abrasive cleaner for grit recycling with vibrating screen for trash removal

- Reverse pulse cartridge dust collector

- Typical size ranging from:

- 10’ W x 10’ H x 10’ L (small)

- 22’ W x 22’ H x 100’ L (large)

-

SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops. The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.SBMGSHeavy Duty Blast Room can be designed for use with any steel or heavy machinery manufacturers, refinishing facilities, for oil and gas components, or in job shops. The "General Purpose Custom Engineered Blast Rooms and Facilities" (SKU: SBMGS) are heavy-duty, long-term sandblasting solutions. Designed for diverse industrial needs, these rooms feature robust steel panels, advanced abrasive recovery systems, and extensive customizability. Ideal for consistent operations seeking a controlled blasting environment.

-

SBMGRDesigned to improve throughput and lower operating costs in Railcar Facilities, these Blast Rooms are suitable to railcar relining, refurb, or new build.SBMGRDesigned to improve throughput and lower operating costs in Railcar Facilities, these Blast Rooms are suitable to railcar relining, refurb, or new build.

-

SBMGWThese blast rooms are designed to improve flow in a Wind Tower manufacturing facility, and can be made to handle both internal and exterior blast, with nearly any level of automation.SBMGWThese blast rooms are designed to improve flow in a Wind Tower manufacturing facility, and can be made to handle both internal and exterior blast, with nearly any level of automation.

My Account

My Account

MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Small Portable Blast Pots

Small Portable Blast Pots Specialty Contractor Pots

Specialty Contractor Pots Robotic / VertiDrive UHP Equipment

Robotic / VertiDrive UHP Equipment Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Mega Bulk Blasters

Mega Bulk Blasters Track Blasters

Track Blasters