Blast Equipment

Showing 16–30 of 77 results

-

BMS200

- 20 cu ft Blast pot

- Excellent for a blastroom application with 2 blasters

- Dual outlet Thompson Valve II abrasive metering valves

- Abrasive capacity

- Garnet 2950 lbs

- Steel Grit 4900 lbs

- Comes with two pneumatic deadman handles and two lengths of control hose (Electric Available)

- Genuine Products - Manufactured by Schmidt to BlastOne specifications

BMS200- 20 cu ft Blast pot

- Excellent for a blastroom application with 2 blasters

- Dual outlet Thompson Valve II abrasive metering valves

- Abrasive capacity

- Garnet 2950 lbs

- Steel Grit 4900 lbs

- Comes with two pneumatic deadman handles and two lengths of control hose (Electric Available)

- Genuine Products - Manufactured by Schmidt to BlastOne specifications

-

FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- Versatile! No need to have separate wet and dry blast equipment. Wet blast or dry blast with a single unit

- Minimal water usage (less than 1 pint / ½ litre per minute) with proprietary Schmidt technology that allows precise control of the amount of water injected into the air stream while blasting

- Abrasive tank is “dry” so there is no need to drain water to refill with abrasive. This creates a significantly cleaner job site and is more efficient

- Schmidt TeraValve™ XL abrasive metering valve offers precise and repeatable control of a wide range of coarse or fine abrasives

- Wide range of blasting pressure capabilities from 10 to 150 psi

- Toggle between wet blast, dry blast, wash-down and blow-off using a single control panel

- This version has a 3.5 C.F. capacity. Other sizes are available upon request - enquire.

-

The Mist Blaster® Wet/Dry 6.5CF Blast Machine (SKU: P-MB65) offers industry-leading flexibility with combo skid and portable with wheels configurations to meet diverse project needs. It delivers powerful dry and wet blasting performance with ultra-low water consumption and enhanced control features. Perfect for professionals requiring precision and reliability on the jobsite.

Features:

- Dual-mode blasting: seamless transition between wet and dry blasting.

- Combo skid options: integrate breathing air packages, air dryers, and more.

- Portable configuration: with wheels for easy transport and setup.

- Ultra-low water use: just 1 pint/minute in MistBlast mode.

- Enhanced control panel: 4 operational modes (Dry Blast, Wet Blast, Wash Down, Blow Down).

- Reliable TeraValve® abrasive metering system for consistent performance.

- Compatible with most abrasives in dry mode; garnet or crushed glass recommended for wet mode.

- High-flow connections maintain optimal nozzle pressure with minimal drop (3 psi typical).

-

Clemco Industries is the world's largest manufacturer of air-powered blasting equipment. It is over 80 years old, being founded in 1941. The Classic line from Clemco is the original design and offers the largest size selection. Excellent for small blasting projects where portability is key, this section includes the 0.5CF (1028 series) and 1.0CF (1042 series). Similar to their larger sisters, these 10" diameter smaller units offer many of the same features including:

- Pneumatic controls with separate inlet & outlet valves, but with ½" piping instead of 1-¼".

- The compact ½" Manual Sand Valve (MSV) - similar to the FSV but specially designed for these smaller units. Note: This valve is designed for expendable mineral and slag abrasives, and is not suited for fine mesh or glass abrasives.

- Pots with TLR-50 controls only, OR full packages including accessories such as the Apollo 20 DLX w/constant flow respirator, 25' blast hose & #4 nozzle, breathing air system (minus the CO monitor, available separately), drop-in screen and more.

- Note: These pots are offered in pressure-release only.

-

FREE Shipping 30 Day Money-Back Guarantee | Free Returns 90 Day Manufacturer Warranty

- The most versatile, easy-to-regulate dry blast machine on the market

- 10-150psi blasting pressure range

- With a load skid combined with an inlet filter, this product uses a differential pressure gauge to allow accurate "metering" of hard-to-flow abrasives like Soda and fine Garnets

- With regulators for the blast and tank pressure for accurate control, this product can be used with most abrasive types - fine to coarse

- With the addition of a media vibrator to improve light media flow and an easy-to-use media shut-off valve this unit is perfect for graffiti removal and all other types of soda blasting

- G2 pneumatic deadman control, 55' twinline control hose, 55' water line with wet blast attachment for dust suppression included with purchase

-

VELOCITY

Technology insertion to exponentially increase shipyard blast and coat production. COMPONENTS & FEATURES The individual technologies include, but are not limited to:

- Intelliblast Blast Pot Controls:

- Smart controls that optimize blasting parameters for maximum efficiency and effectiveness.

- Snakebite Blasting Nozzles

- High-performance nozzles designed for precise and powerful material removal, reducing blasting time and lowering process noise.

- Rapidly Deployable Containments

- Innovative containment systems that can be quickly deployed, ensuring a controlled environment, and minimizing the spread of contaminants.

- Vortex Airflow Movement

- Proprietary airflow design that lowers energy consumption, enhances ventilation, and ensures the efficient removal of particles from the blasting and painting areas.

- Combination Dual Air Plenums

- Dual air plenums that provide a uniform and controlled airflow, optimizing the blasting and painting processes.

- Energy Recovery System (ERS)

- An energy recovery system that captures and recycles heat energy, reducing overall energy consumption and operational costs

BENEFITS

- Faster production cycles

- Reduced operational costs

- Enhanced environmental sustainability

- Improved worker safety

VELOCITYTechnology insertion to exponentially increase shipyard blast and coat production. COMPONENTS & FEATURES The individual technologies include, but are not limited to:

- Intelliblast Blast Pot Controls:

- Smart controls that optimize blasting parameters for maximum efficiency and effectiveness.

- Snakebite Blasting Nozzles

- High-performance nozzles designed for precise and powerful material removal, reducing blasting time and lowering process noise.

- Rapidly Deployable Containments

- Innovative containment systems that can be quickly deployed, ensuring a controlled environment, and minimizing the spread of contaminants.

- Vortex Airflow Movement

- Proprietary airflow design that lowers energy consumption, enhances ventilation, and ensures the efficient removal of particles from the blasting and painting areas.

- Combination Dual Air Plenums

- Dual air plenums that provide a uniform and controlled airflow, optimizing the blasting and painting processes.

- Energy Recovery System (ERS)

- An energy recovery system that captures and recycles heat energy, reducing overall energy consumption and operational costs

BENEFITS

- Faster production cycles

- Reduced operational costs

- Enhanced environmental sustainability

- Improved worker safety

- Intelliblast Blast Pot Controls:

-

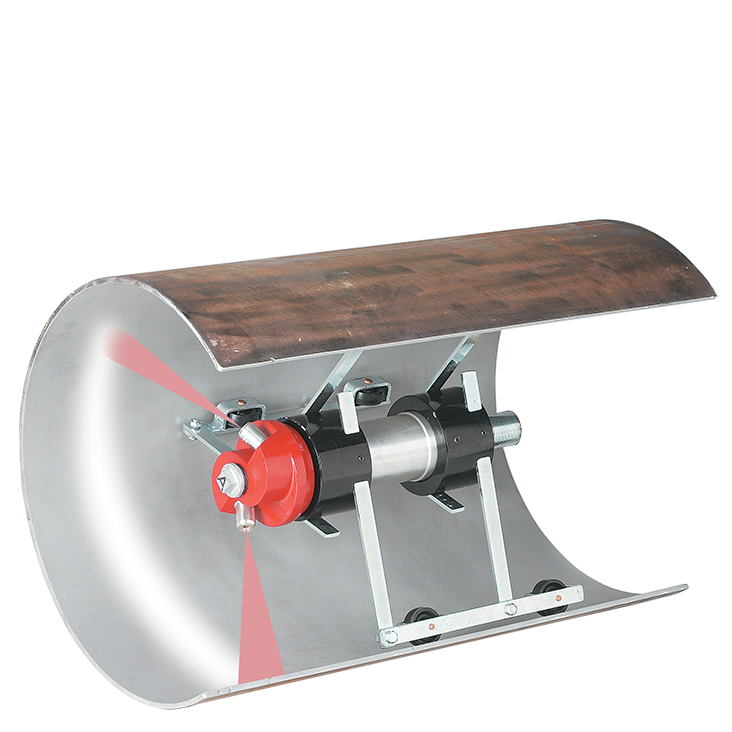

IPC1000The RotorBlast is the fastest way to blast the internals of pipes. This IPC1000 version is designed for pipes from 10" to 35" ID. Fast and effective blasting is ensured by the twin-nozzle spinning blast head. Additional details of this Internal Pipe Blaster are as follows:

- 360 degree blasting covers the entire ID of the pipe

- Speed is manually controlled. Optional electric winch is also available, helping to save labor and aid consistency in results.

- This IPC1000 pipe blasting tool works in pipes 10" to 35" ID

- Nozzles sold separately - details below:

- 2 nozzles are required for this unit.

- Use BNAT nozzles for pipes from 8" to 11" ID.

- Use BNASB nozzles for pipes from 12" to 36" ID.

- Centering carriage sold separately - details below:

- IPC1200 Centering Carriage is required and is adjustable to work in pipes from 8 to 36" in diameter.

- Note: ID blasting equipment requires significant maintenance. A Rotorblast Repair Parts Kit is available for convenience, or individual parts may be purchased under the Parts Tab. An operators manual is shown under the documents tab or you can contact us for further information.

IPC1000The RotorBlast is the fastest way to blast the internals of pipes. This IPC1000 version is designed for pipes from 10" to 35" ID. Fast and effective blasting is ensured by the twin-nozzle spinning blast head. Additional details of this Internal Pipe Blaster are as follows:- 360 degree blasting covers the entire ID of the pipe

- Speed is manually controlled. Optional electric winch is also available, helping to save labor and aid consistency in results.

- This IPC1000 pipe blasting tool works in pipes 10" to 35" ID

- Nozzles sold separately - details below:

- 2 nozzles are required for this unit.

- Use BNAT nozzles for pipes from 8" to 11" ID.

- Use BNASB nozzles for pipes from 12" to 36" ID.

- Centering carriage sold separately - details below:

- IPC1200 Centering Carriage is required and is adjustable to work in pipes from 8 to 36" in diameter.

- Note: ID blasting equipment requires significant maintenance. A Rotorblast Repair Parts Kit is available for convenience, or individual parts may be purchased under the Parts Tab. An operators manual is shown under the documents tab or you can contact us for further information.

-

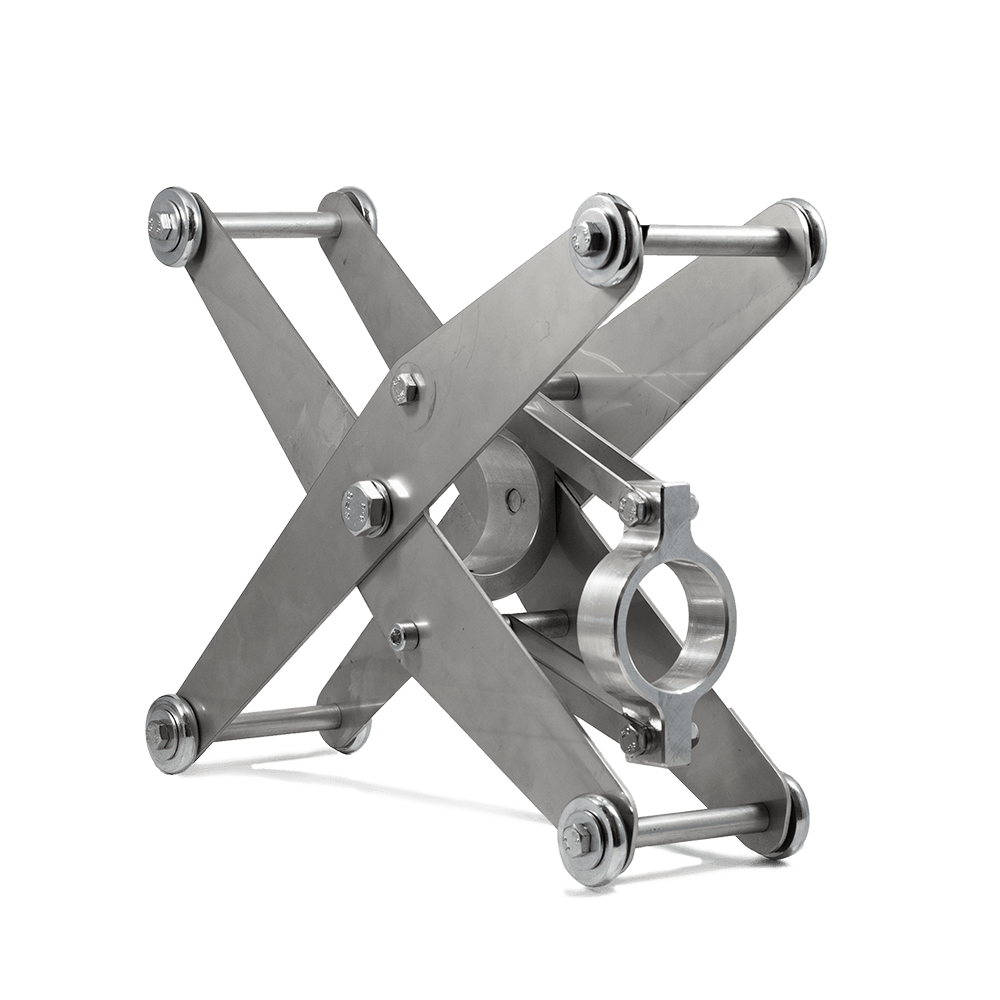

Clemco offers a wide range of equipment that provides high-efficiency 360-degree cleaning for pipe interiors. Suitable for industrial applications, these tools are capable of providing precise and effective surface preparation.

The two Hollo-Blast unit versions function essentially as nozzles, and work by utilizing a deflection tip at the end of the orifice. The tip deflects the abrasive into a 360° pattern. They are designed for pipes ranging from only ¾" - 2" ID (Junior Series) to 2" to 12" ID (standard Hollo-Blast Series). Larger ID pipe can also be done, but with a different series of equipment. Optional centering carriages are also available, adding efficiency and consistency to the blast.

Internal Pipe blasting is a specialized process involving high wear on certain components. BlastOne's technical staff is available to assist with your questions.

-

IPC3100

- Easy setup

- Tungsten carbide deflection head and throat nozzle

- For pipes 3/4" to 2" ID

- Includes 'hex collar' centering carriage set

- Requires 120 CFM air supply

- Adapts to customer supplied length of 3/8" threaded lance

- Compatible with standard blast machines

IPC3100- Easy setup

- Tungsten carbide deflection head and throat nozzle

- For pipes 3/4" to 2" ID

- Includes 'hex collar' centering carriage set

- Requires 120 CFM air supply

- Adapts to customer supplied length of 3/8" threaded lance

- Compatible with standard blast machines

-

SBPL05WElevate your paint booth's efficiency and safety with the Liftman Pneumatic Paint Booth Personnel Manlift, Twin Wheel Version, SKU: SBPL05W. This pneumatic lift is ideal for explosion-sensitive areas, reaching a working height of up to 14' 9".

- Twin Wheel Version for stable and smooth operation.

- Pneumatically operated, ensuring safety in explosive environments.

- Self-centering steering for effortless maneuverability.

- CE, CAS, UL certified and ATEX compliant.

SBPL05WElevate your paint booth's efficiency and safety with the Liftman Pneumatic Paint Booth Personnel Manlift, Twin Wheel Version, SKU: SBPL05W. This pneumatic lift is ideal for explosion-sensitive areas, reaching a working height of up to 14' 9".- Twin Wheel Version for stable and smooth operation.

- Pneumatically operated, ensuring safety in explosive environments.

- Self-centering steering for effortless maneuverability.

- CE, CAS, UL certified and ATEX compliant.

-

BAWH10110V

- Designed for use with the rotorblast and cone blasters when ID blasting

- Semi-automatically feeds the blast hose at a consistent rate through the pipe being blasted

- Ensures a consistent blast pattern vs manual handling of the hose

BAWH10110V- Designed for use with the rotorblast and cone blasters when ID blasting

- Semi-automatically feeds the blast hose at a consistent rate through the pipe being blasted

- Ensures a consistent blast pattern vs manual handling of the hose

-

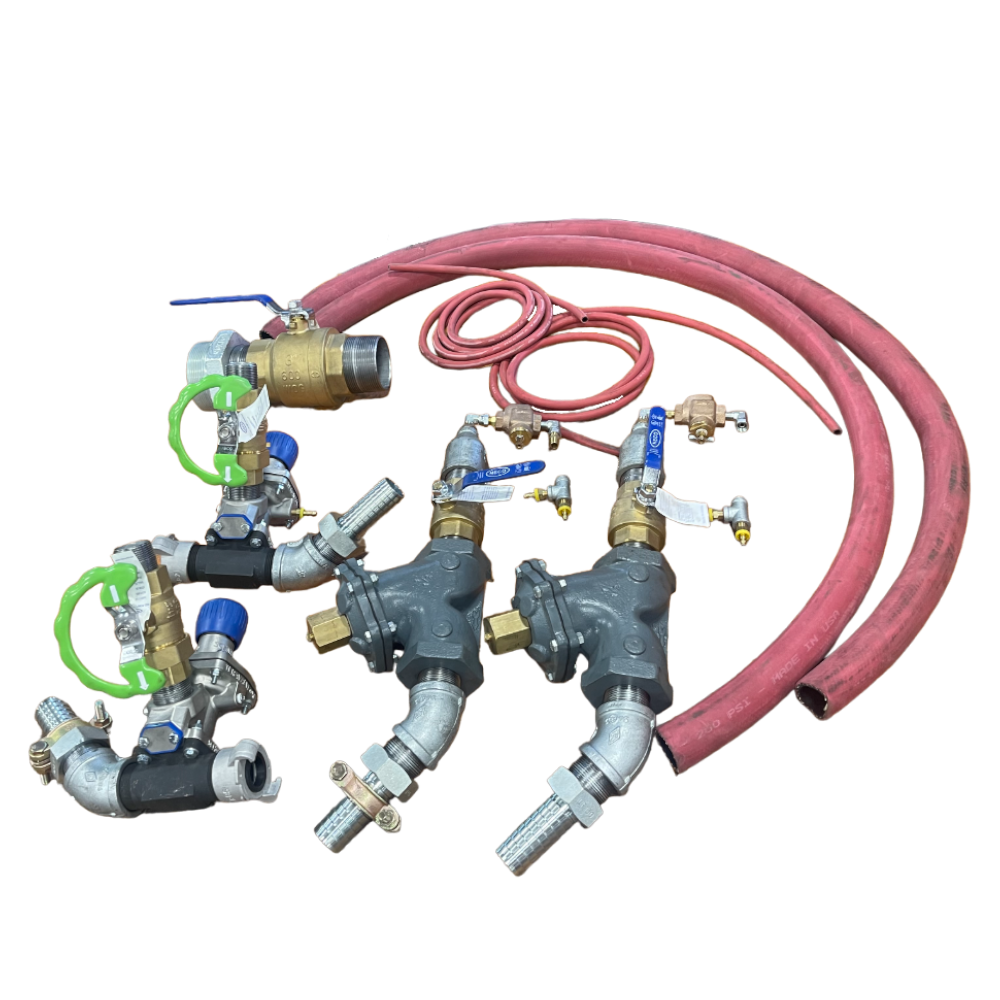

Upgrade old technology Bulk pots from donut valves & pinch valves to state-of-the-art TeraValve systems using a retrofit kit. Available in 2 or 4 outlet configurations. The CEN Mega Exhaust Muffler retrofit kit is a common option that can be conveniently added when performing this retrofit. Note: matching Junction Box is available separately. Retrofitting is recommended only for mega blasters with good structural integrity. These are the parts kits only. BlastOne can perform the retrofit if desired - contact us for pricing and details.

-

VCVRS3

- This Blast and Vacuum BRS system is built for high production vacuum blasting work.

- The Vacuum system, blast machine and airdryer are all mounted to one skid.

- The abrasive does not recycle which is ideal when you have very low dust requirements or when your specification calls for the use of virgin abrasive only.

- This system is 100% pnuematic and does not require any electrical power.

- Blast Pot capacity is 3.5 cuft.

- Blast upto 60 sqft / 6 sqm per hour

- Requires 750cfm of air

VCVRS3- This Blast and Vacuum BRS system is built for high production vacuum blasting work.

- The Vacuum system, blast machine and airdryer are all mounted to one skid.

- The abrasive does not recycle which is ideal when you have very low dust requirements or when your specification calls for the use of virgin abrasive only.

- This system is 100% pnuematic and does not require any electrical power.

- Blast Pot capacity is 3.5 cuft.

- Blast upto 60 sqft / 6 sqm per hour

- Requires 750cfm of air

-

SBMGE

- Modified High-cube-style shipping container construction (20 ft, 40 ft)

- Watertight, Weatherproof design

- Completely self-contained for maximum portability

- Simple setup/installation

- Partial abrasive recovery system, with shovel-in hopper

- Available as fully assembled unit or retrofit kit

- Instant Preliminary Quotes Available on Request!

SBMGE- Modified High-cube-style shipping container construction (20 ft, 40 ft)

- Watertight, Weatherproof design

- Completely self-contained for maximum portability

- Simple setup/installation

- Partial abrasive recovery system, with shovel-in hopper

- Available as fully assembled unit or retrofit kit

- Instant Preliminary Quotes Available on Request!

My Account

My Account

MistBlaster Wet / Dry Pots

MistBlaster Wet / Dry Pots Small Portable Blast Pots

Small Portable Blast Pots Specialty Contractor Pots

Specialty Contractor Pots Robotic / VertiDrive UHP Equipment

Robotic / VertiDrive UHP Equipment Internal Pipe (ID) Systems

Internal Pipe (ID) Systems Mega Bulk Blasters

Mega Bulk Blasters Track Blasters

Track Blasters