Blast Equipment Parts

Showing 16–30 of 352 results

-

The latest innovation in deadman safety technology from Axxiom is the BAABS (Blasting Accessories and Assist Bracket System). Intended to be the safest deadman on the market, it mechanically prevents inadvertent activation. The Schmidt BAABS deadman is such a leap forward in safety technology that Axxiom provides them as standard equipment with most new blast pot or valve retrofit purchases.*

All BAABS use the Axxiom G3 trigger deadman configurable as either electric or pneumatic.

All BAABS units are capable of being fitted with the BAABS blast light for improved vision in dim or dusty environments. (Note: When the light is used with the Subcompact BAABS, there is not room for the thrust brace.)

*The standard configuration provided with new equipment is the Compact size. See Product Description tab for all size options.

-

ASEPDOD3When using the Sponge-Jet B-Vac integrated blast system, using a stand-alone cyclonic separator in-line with the vacuum hose is often desireable. This unit can be placed next to the B-Vac and reduces the dust load on the B-Vac dust filter. The Sponge-Jet dropout drum can also be used in any sponge media recovery application. It comes with a 3 inch vacuum hose port and is can be used with a vacuum hose fitted with a cam lock fitting. Vacuum hose, camlock fittings, and vacuum pick-up tools available separately. Note: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or send in the web form quote request.ASEPDOD3When using the Sponge-Jet B-Vac integrated blast system, using a stand-alone cyclonic separator in-line with the vacuum hose is often desireable. This unit can be placed next to the B-Vac and reduces the dust load on the B-Vac dust filter. The Sponge-Jet dropout drum can also be used in any sponge media recovery application. It comes with a 3 inch vacuum hose port and is can be used with a vacuum hose fitted with a cam lock fitting. Vacuum hose, camlock fittings, and vacuum pick-up tools available separately. Note: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or send in the web form quote request.

-

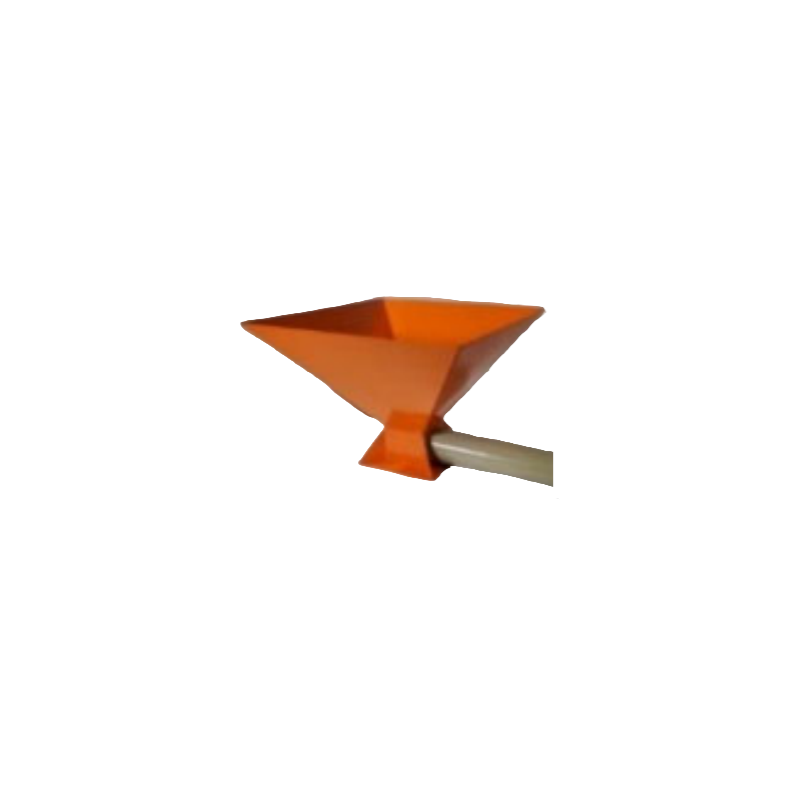

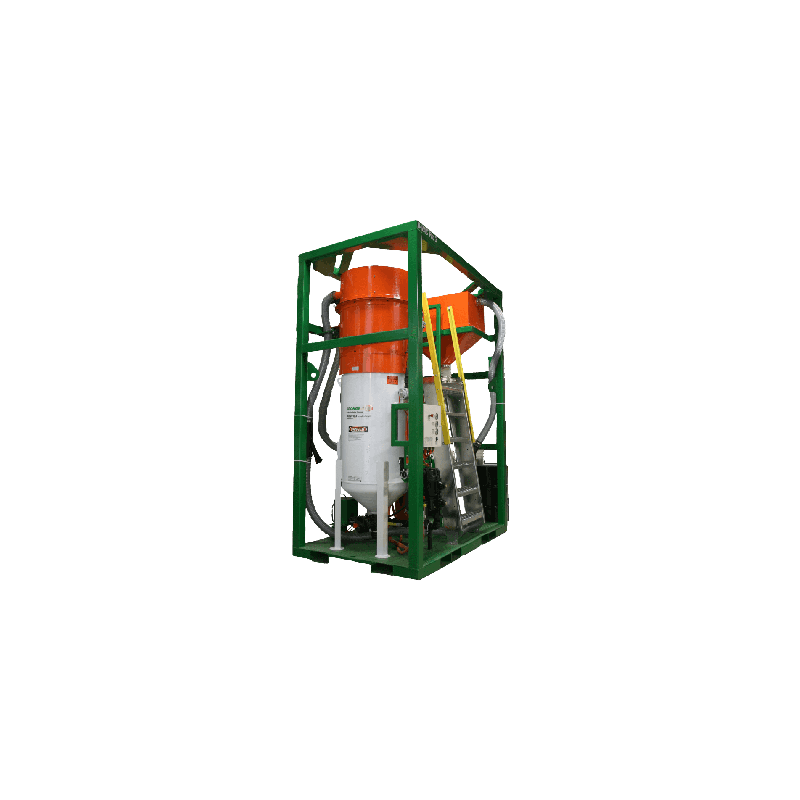

ASEPMRHThis Media Recovery Hopper is used in vacuum recovery of sponge media. Vacuum hose and vacuum tools available separately - see You May Also Like below. Note: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or send in the web form quote request. This product will be less costly if purchased with the initial blast equipment rather than on it's own.ASEPMRHThis Media Recovery Hopper is used in vacuum recovery of sponge media. Vacuum hose and vacuum tools available separately - see You May Also Like below. Note: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or send in the web form quote request. This product will be less costly if purchased with the initial blast equipment rather than on it's own.

-

Recycler screens are available in various mesh sizes, allowing optimization of dust removal or media recycles, whatever your application requires. These screens are for the 70 series recyclers. Screens are also available for the 35 series - enquire. NOTE: Due to our distribution agreement with Sponge-Jet, pricing is not shown on our website. Contact us for fast, competitive pricing or sent your request via our web quote link.

-

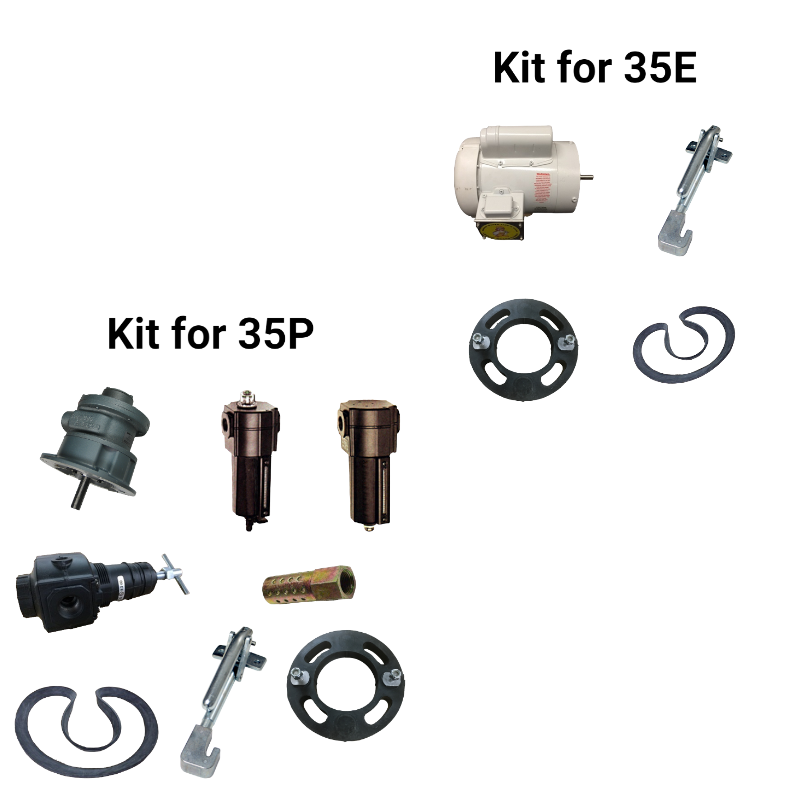

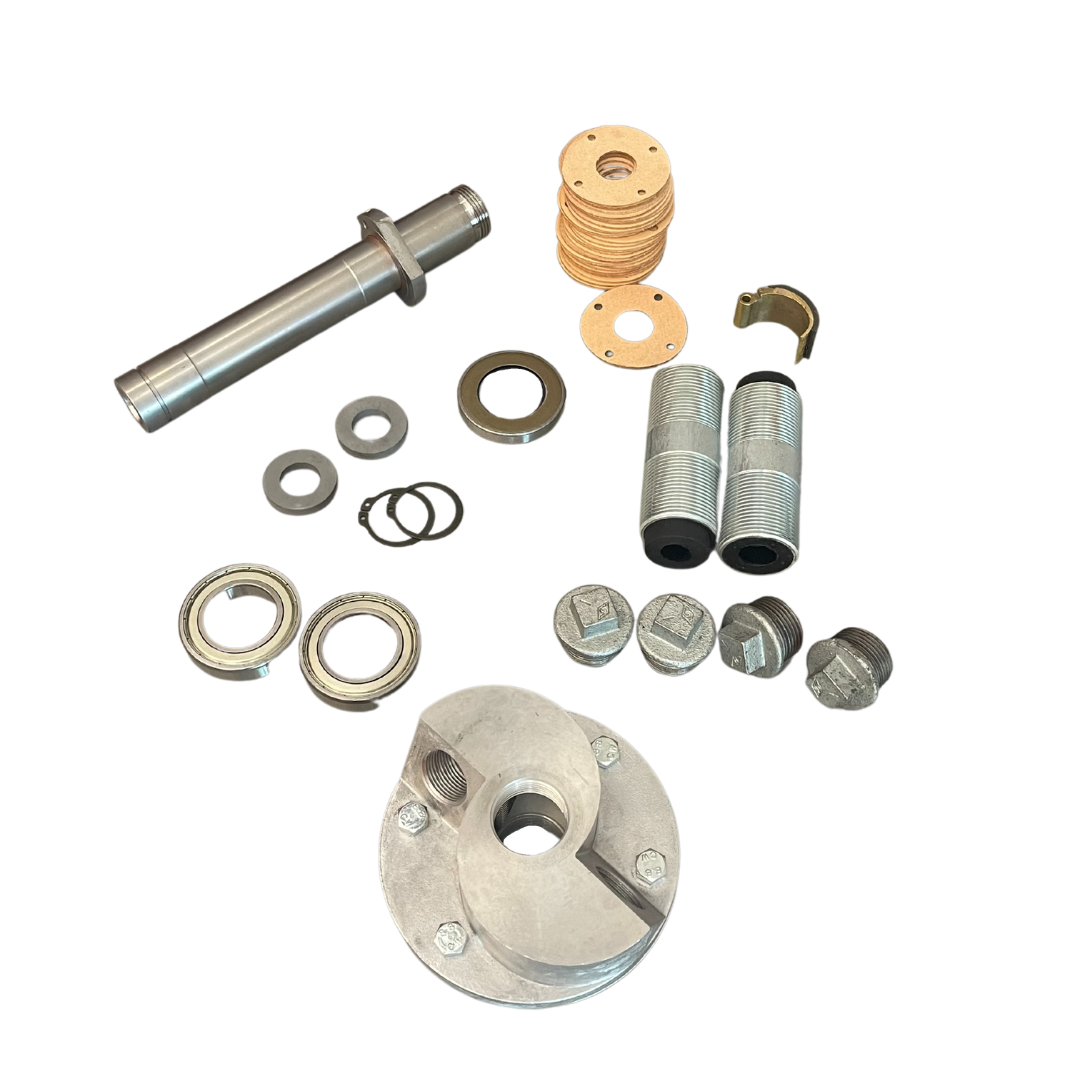

Sponge-Jet offers a robust repair kit for each of their recycler models. Pictured are the kits for the 35 series units (other series kits are similar with the appropriate substitutions). Included items are as follows:

- Electric Recycler kits:

- Electric motor

- Flexible coupling

- 4 flat gaskets

- 2 clamps

- Pneumatic Recycler kits:

- Air motor

- Lubricator

- Moisture separator

- Muffler

- Filter

- Flexible coupling

- 4 gaskets

- 2 clamps

- Electric Recycler kits:

-

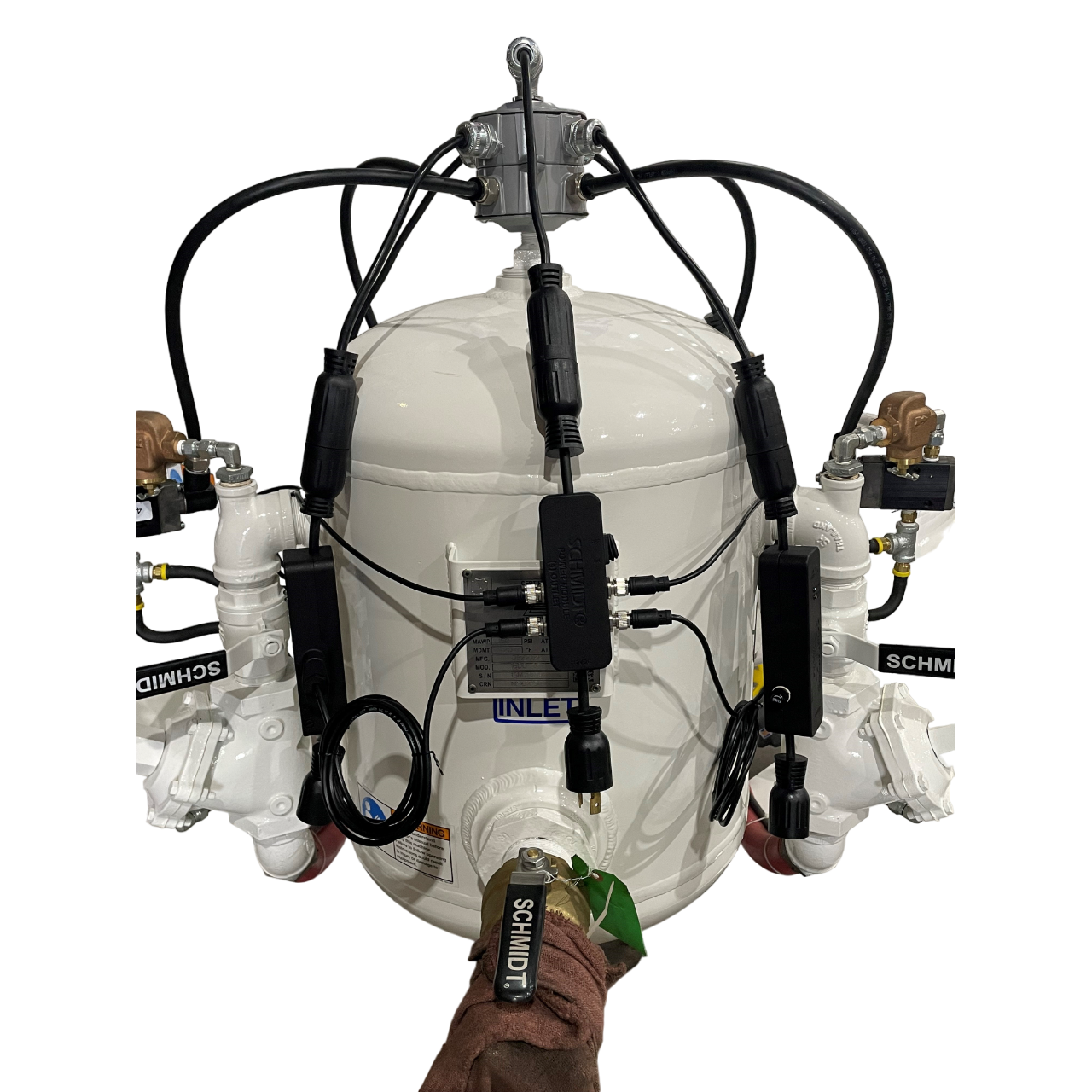

The SmartSPARKTM Short Proof Deadman Control System is enhancing blaster safety in all blast operations. Designed to address inadvertent activations caused by electrical shorts in deadman control lines, the SmartSPARK Deadman System keeps your blasters safe. The SmartSPARK Deadman and Controls has a closed loop system, that will detect an electrical short in the deadman line and shut off the blast pot instantly.

- Designed to quickly retrofit onto existing Schmidt blast pots with electrical deadman controls

- Reduces the likelihood of accidental start-ups by detecting and responding to electrical shorts

- 2 models avaliable - single outlet and 4-operator outlet.

- Ideal for blastrooms that have steel grating and blast sites where multiple operators are working simultaneously.

-

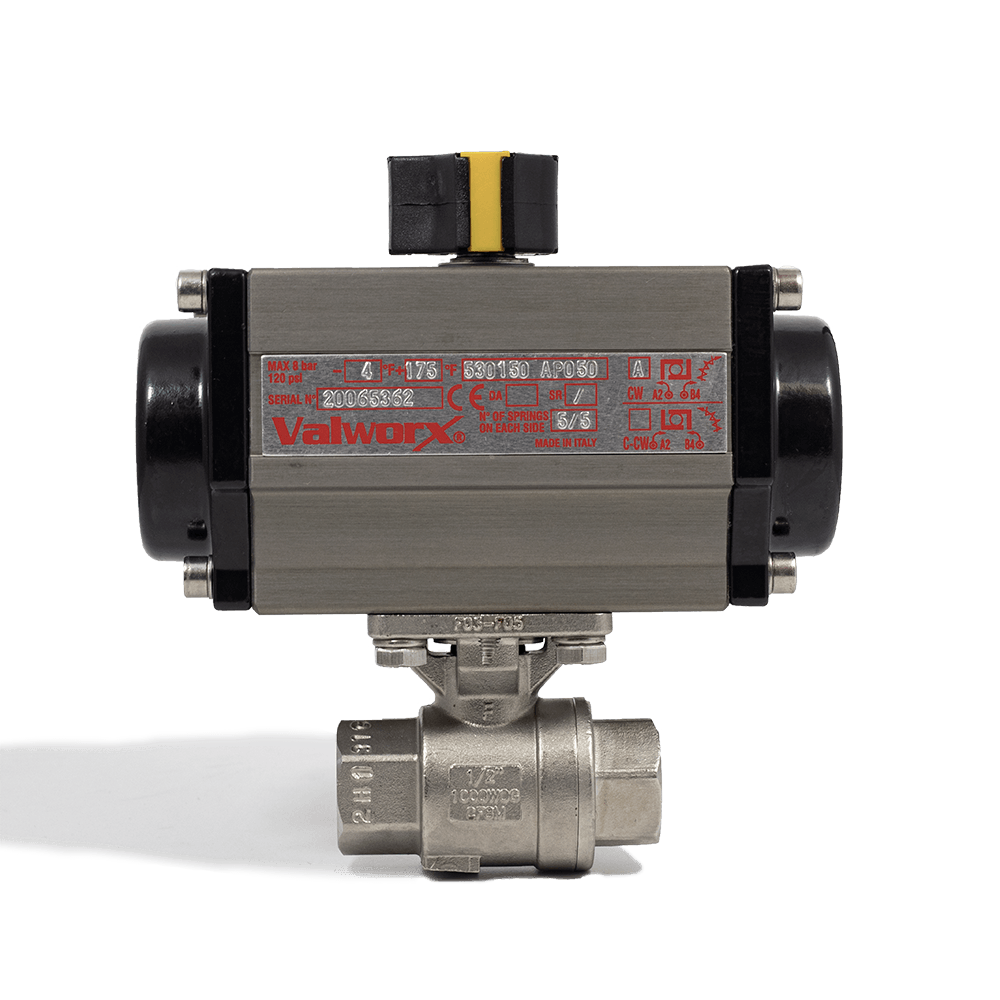

OEM Clemco Inlet Valves are genuine replacement parts designed for compatibility with TLR-50, TLR-100, and TLR-300 Remote Control Systems. Available in multiple sizes, these inlet valves ensure optimal performance and reliability for your blasting operations.

Key Options:

- 1/2-Inch Inlet Valve: Replacement for TLR-50 Remote Systems.

- 1-Inch Inlet Valve: For TLR-100 Remote Systems, compatible with certain 3 cuft and 6 cuft blast machines.

- 1-¼ - 1-½ Inch Inlet Valve: Replacement for TLR-300 Remote Systems with a 1-1/4" outlet.

-

Clemco Brass Fittings ensure secure, corrosion-resistant connections in harsh industrial environments. Shop here for the flared (JIC) fittings, NPT fittings and more that you need for control valves, metering valves, and hoses!

-

OEM Clemco blast machine lids and screens are useful accessories for many applications. Lids keep the pots from collecting debris - especially when used outdoors. Screens are highly recommended for preventing foreign matter out of the pot when refilling abrasive. They are standard with most new Clemco blast machine packages, but lids are optional. Both are available here in sizes to match any size blast pot from 0.5CF (10") to 20 CF (36").

-

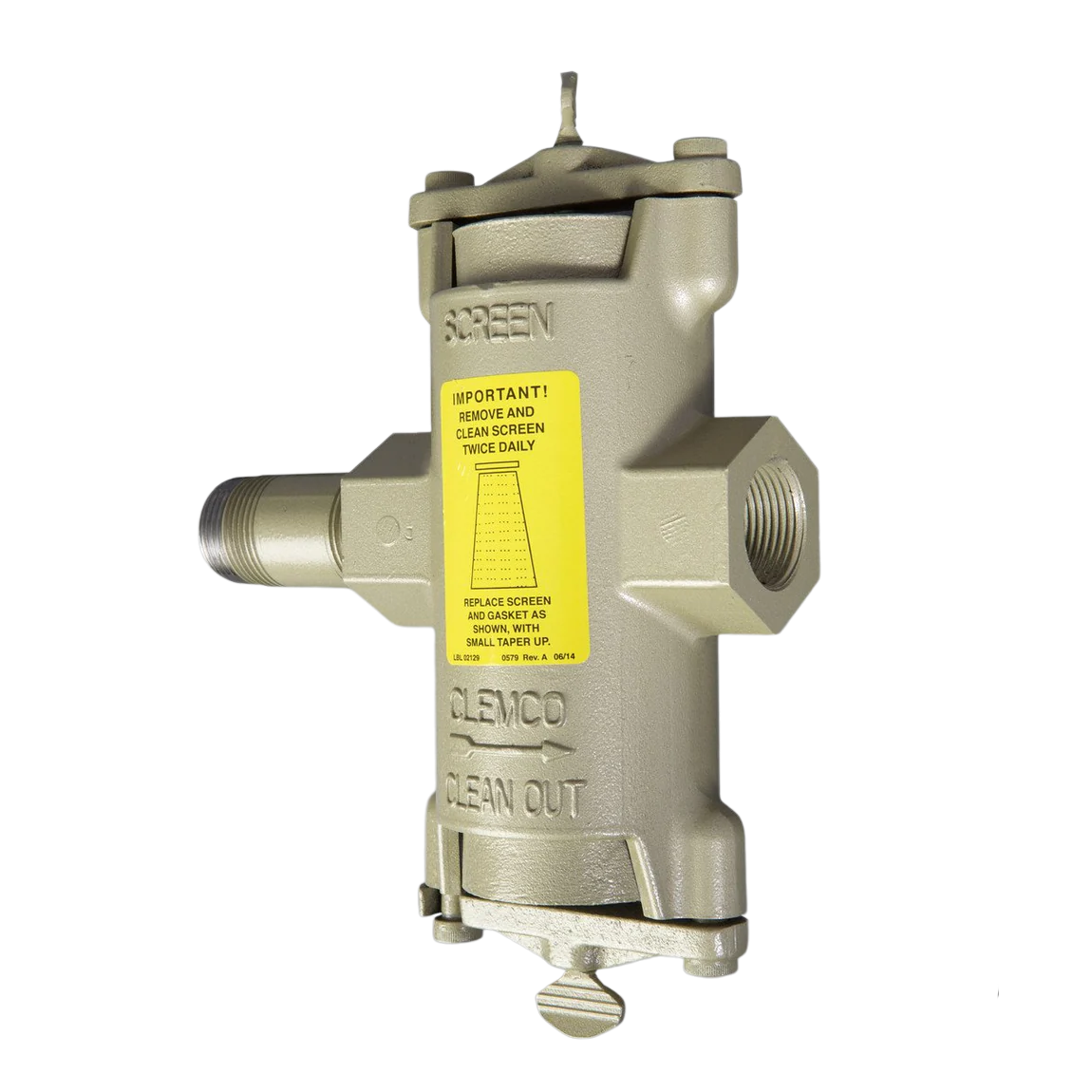

The Clemco 1-Inch Abrasive Trap ensures reliable abrasive containment and system protection. Designed for compatibility with TRL-100 and TLR-300 Remote Systems, this complete abrasive trap features a 1-inch National Pipe Thread (NPT) connection, making it essential for maintaining blasting efficiency and equipment longevity. Key Features:

- 1-inch NPT connection for secure integration

- Compatible with TRL-100 and TLR-300 Remote Systems

- Complete assembly for easy installation

- Durable construction for long-lasting performance

-

- Clemco TLR-50 / TLR-300 Deadman Controls are the primary safety system for Clemco Classic Series pneumatic blast machines

- Ensure automatic deactivation if the operator loses control of the blast nozzle.

- The system can be configured in various ways, depending on the blast machine, what media is being used, and what features are needed.

- The Clemco control systems in this section are complete systems. Complete systems are necessary only when completely refurbishing a pot.

- Individual valves and other repair components are available separately.

-

Genuine OEM Clemco Outlet Valves ensure reliable performance and longevity for your blasting operations. Available in piston and diaphragm styles, these outlet valves are designed to accommodate a variety of remote control systems and abrasive types, offering superior durability and versatility.

Key Options:

- 1-Inch Piston Outlet Valve: Ideal for standard applications with remote controls.

- 1/2-Inch Diaphragm Outlet Valve: Suited for TRL-50 pneumatic remote controls.

- 1-Inch Diaphragm Outlet Valve: Perfect for TRL-100/300 controls and fine or aggressive abrasives.

-

BAP03699Maintenance of the pop-up assembly is essential for preventing differential pressure issues in blast machines. BlastOne offers OEM Clemco repair parts including this pop-up valve & shaft assembly (with external sleeve). This 4" size dome is used in all current sizes of Clemco pots between 1.5 and 20 c.f. It is commonly used with either the Clemco 02325 rubber seating ring (standard applications) or the Clemco 02380 neoprene seating ring (use in hot climates). MPN: 03699BAP03699Maintenance of the pop-up assembly is essential for preventing differential pressure issues in blast machines. BlastOne offers OEM Clemco repair parts including this pop-up valve & shaft assembly (with external sleeve). This 4" size dome is used in all current sizes of Clemco pots between 1.5 and 20 c.f. It is commonly used with either the Clemco 02325 rubber seating ring (standard applications) or the Clemco 02380 neoprene seating ring (use in hot climates). MPN: 03699

-

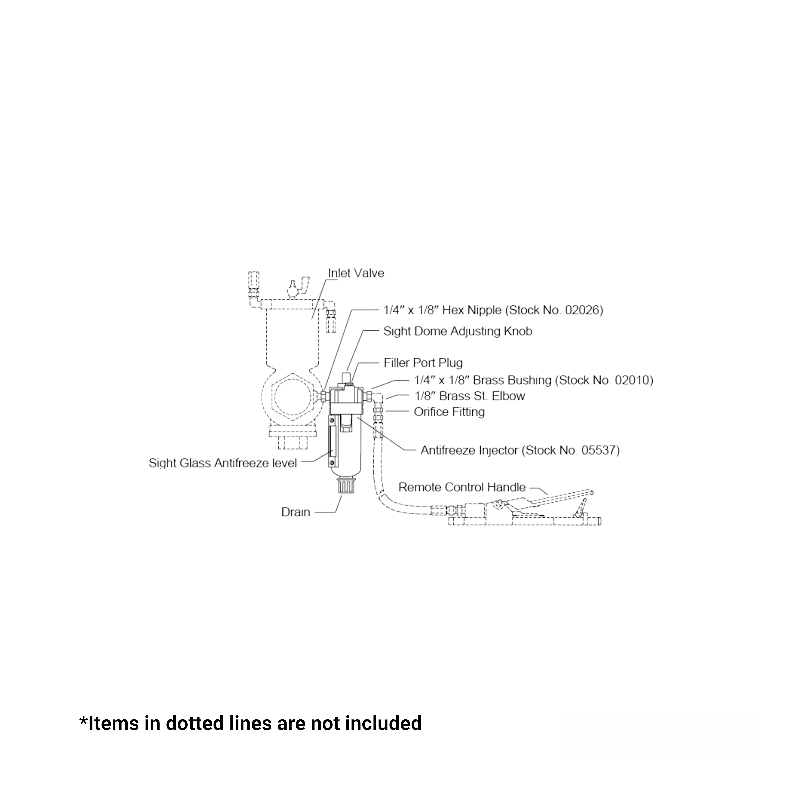

AFAL05537Maintain safe operation of pneumatic deadman systems during cold temperatures with this antifreeze injector kit. Designed for all Clemco pneumatic control systems, this injector assembly can prevent the deadman from dangerous icing. MPN: 05537AFAL05537Maintain safe operation of pneumatic deadman systems during cold temperatures with this antifreeze injector kit. Designed for all Clemco pneumatic control systems, this injector assembly can prevent the deadman from dangerous icing. MPN: 05537

Explore our extensive range of blast equipment parts designed to enhance and maintain your blasting operations. From deadman control systems to high-pressure fittings, we provide everything you need to keep your equipment running smoothly and efficiently. Our selection includes durable components like hex pipe nipples, pop-up valves, and hose fittings, ensuring compatibility and high performance. Trust in our products to deliver reliability and safety across all your blasting projects.

My Account

My Account

Abrasive Metering Valves & Parts

Abrasive Metering Valves & Parts Air Control Valves & Related

Air Control Valves & Related Deadman / Control Systems

Deadman / Control Systems General Repair Parts for Blast Pots

General Repair Parts for Blast Pots Internal Pipe (ID) System Components

Internal Pipe (ID) System Components MistBlaster Specific Parts

MistBlaster Specific Parts Sponge Blast Equipment Parts

Sponge Blast Equipment Parts Vacuum Blaster Workheads, Parts & Related

Vacuum Blaster Workheads, Parts & Related VertiDrive Specific Parts

VertiDrive Specific Parts