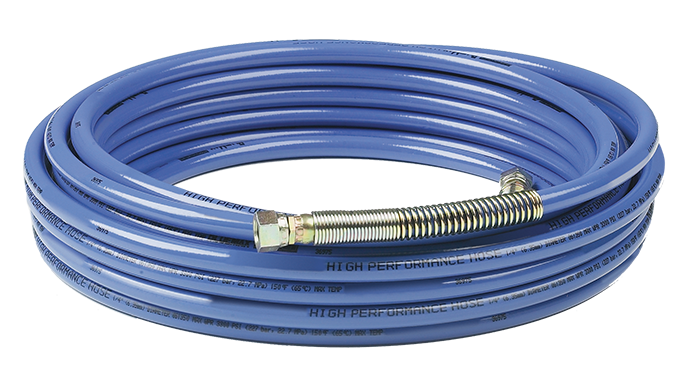

Airless Hoses & Related

Our range of airless hoses and related accessories is designed to meet the rigorous demands of industrial spraying applications. With options like high-pressure elbow adapters, inline swivels, and various union adapters, you can customize your setup for optimal performance. Each product is built to handle high-pressure environments, ensuring safety and efficiency in every use.

If you require specific sizes or configurations not listed, please contact us for assistance or use the live chat feature in the bottom right of the browser window.

Showing all 6 results

Airless hoses and related accessories are critical for ensuring the smooth and efficient operation of airless spray systems. These components, including hoses, adapters, and fittings, are designed to withstand high pressures and provide reliable connections. High-quality airless hoses offer flexibility and durability, making them ideal for demanding industrial applications. Whether you need a whip hose for enhanced maneuverability or a high-pressure nipple fitting for secure connections, our selection of airless hoses and accessories ensures you have the right tools for any spray job.

My Account

My Account

Accessories for Airless Systems

Accessories for Airless Systems Airless Gun Tips

Airless Gun Tips Airless Spray Guns & Tips

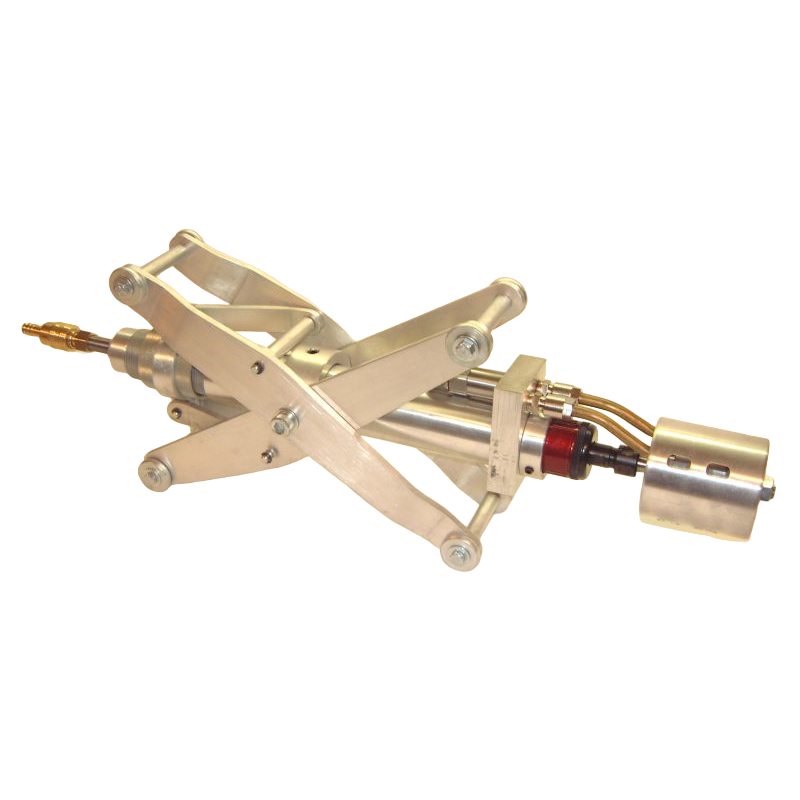

Airless Spray Guns & Tips Internal Pipe Coating Systems

Internal Pipe Coating Systems Parts & Fittings Airless Spray Equipment

Parts & Fittings Airless Spray Equipment Plural Equipment

Plural Equipment Repair Parts for Airless Guns

Repair Parts for Airless Guns Airless Spray Pumps

Airless Spray Pumps