Blast & Paint Solutions for Oil & Gas

BlastOne’s provides innovative technologies, and proven methodologies address the common challenges faced by our customers. Our technology makes surface preparation Faster, Safer and Cleaner.

Whether you are building a new facility to fabricate key components for Asset Owners, or doing abrasive blasting and painting on a oil storage tank or pipeline, we have a unique solution for you. The abrasive blasting market is quickly trending toward the use of robotics, and BlastOne is leading that change.

Blast and Paint Facility Design

BlastOne specializes in designing and building pre-engineered and custom blast and paint facilities for the oil and gas sector. Our solutions are configured to meet your specific needs, from full green-field construction to automated robotic systems and retrofitting existing facilities. We provide anything from a small 10×10 booth up to turnkey, fully automated solution to suit your application and budget.

OIL & GAS BLAST AND PAINT HALL APPLICATION

BlastOne provides a diverse selection of high-performance products designed to meet the unique challenges of the oil & gas industry:

Blast & Paint Facility with Aquatec

Industrial Partial Recovery Blast Room

Interior Semi-Down Draft

Blast Shed with H-Shape Recovery

Heavy Duty Blast Room

Full-Down Draft Paint Room with Manlift and Aquatec

Blast & Paint with Innovative Material Handling

Pass Through Heavy Duty Blast Room

THE PROCESS TO A GREAT OUTCOME

Most people only build a blast and paint facility once in their life-time, so we have designed a process that will guide you to the ultimate solution that fits your needs and budget. To0 often people engage an engineering company or the friend of a friend to specify what they need, before going out to companies like ours to ask for a 10ft x 40ft facility that will likely not always suit their long-term needs…

This industry is small and very niche and we follow a Design | Bid | Build methodology. Our process has been formulated over decades and always begins with a thorough assessment of your facility’s requirements, followed by detailed planning, design before construction.

A deep dive into our Approach and What to Expect

BlastOne delivers high-performance, cost-effective blasting and painting facilities through integrated design, construction, and long-term support. From concept to completion, we tailor solutions to client needs, reducing risks and streamlining processes. With 45+ years of expertise, we provide ongoing support, including maintenance, training, and readily available consumables, ensuring reliability throughout the facility’s life cycle.

ENHANCING OPERATIONAL EFFICIENCY THROUGH CAPACITY STUDIES

BlastOne has a team of experienced production planners that systematically analyze your production planning schedules and future work to ensure the facility you build is right-sized and suited for your growth.

Capacity Studies are designed to systematically analyze and improve the efficiency of blasting and painting operations. By assessing workflows and identifying bottlenecks, these studies provide practical solutions aimed at enhancing productivity and reducing costs.

Key Components of Capacity Studies:

-

-

-

Workflow Assessment

A thorough evaluation of current processes to identify inefficiencies.

-

-

-

Bottleneck Identification

Detection of areas that impede productivity.

-

-

-

Implementation of Solutions

Application of targeted improvements tailored to specific operational needs.

-

-

Sustained Efficiency

Development of strategies to ensure long-term operational gains.

-

CASE STUDY: Steel Fabricator More than Doubles Efficiency

-

Doubled Efficiency: Achieved record-breaking production throughput with only half the personnel, allowing the team to take on larger projects without expanding labor costs.

-

Accelerated Turnaround Times: Reduced paint curing times by an astonishing 75%, from 12 hours to just 3-4 hours, slashing delays and meeting tight deadlines effortlessly.

-

Enhanced Worker Performance and Safety: Improved visibility and ventilation created a safer, more productive environment for blast and paint crews, reducing fatigue and errors.

-

Streamlined Operations: Advanced handling systems ensured seamless workflow, boosting reliability and freeing up valuable time for final assembly and quality control.

EVERY JOURNEY STARTS WITH A PHONE CALL

Connect with a professional today.

Blast Projects

PIPELINES

With almost 200,000 miles of liquid pipelines and 2.4 million miles of natural gas pipelines (American Petroleum Institute), the annual cost for maintenance is high. Learn how you can improve your bottom line:

TANKS

Corrosion occurs on both the inside and outside of tanks. A corrosion control system has to work hard to protect tanks. Need to blast acres of steel quickly? Learn how BlastOne makes easy work of tanks of any size:

Robotic Solutions

Pipeline Robotic Equipment

Designed to abrasive blast and paint the internals of pipelines or penstocks, the Internal Pipe Robots use 3 large nozzles and will blast 10x faster than a standard blast set up using manual labor.

Vertidrive Blasting Robot

Blast 7x Faster when removing coatings from an old Oil Storage Tank. This magnetic blast robot can hold 3 large blast nozzles and outperform a crew of 7 men.

Robotic Blast Facilities

Blastman robots boast production of up to 2,000 sqft/hr. Designed for installation in blasting facilities.

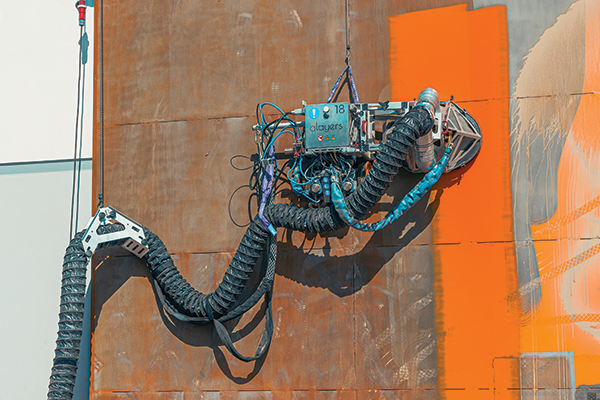

Q-Layers Painting Robot

Airless spraying robotically at heights with robotic paint is now a reality, will perform as fast as 20 men with brush and roll.

Vertidrive UHP Coating Removal

Using Ultra-High Pressure water, this Vertidrive robot will remove an old thick coating in a 14” path.

ENHANCE EFFIIENCY AND PRECISION WITH ROBOTIC & COATING SOLUTIONS

Connect with a professional today to learn more.

Performance3 Analytics

OPTIMIZING SURFACE PREPARATION: THE PERFORMANCE3 ADVANTAGE

PEATS – How to optimize your current repair process.

-

-

Process (P)

We decide what is the process and/or method of surface preparation for the project at hand, taking into account any unique challenges.

-

-

-

Equipment (E)

Determine which equipment combination will give you the safest and greatest performance.

-

-

-

Abrasive (A)

Different jobs may require different abrasives. Working from the specification and application backwards, we select the right abrasive to most efficiently achieve the results required.

-

-

-

Technology (T)

IntelliBlast providing real-time results from the field to ensure operations requirements and expectations are being met, and exceptions are being managed.

-

-

Sustain (S)

Follow through on the improvements made through real-time monitoring, onsite support, on-the-tools training and regular reporting.

NEED HELP SELECTING THE RIGHT EQUIPMENT FOR YOUR OIL & GAS PROJECT?

Check out our Blasting and Spray Equipment Buying Guides for detailed recommendations tailored to your needs.

Case Studies

STEFFES CORPORATION BRINGS FINISHING OPERATIONS IN-HOUSE, ENHANCING EFFICIENCY AND CONTROL

Steffes Corporation, a steel fabricator in North Dakota, transitioned its abrasive blasting and painting processes from subcontractors to an in-house setup. Collaborating with BlastOne, they designed and installed a blast room, paint booth, paint kitchen, and abrasive vacuuming system within a confined space. This move has reduced project costs and improved production scheduling, providing Steffes with a competitive edge.

— Steffes Corporation

STEEL FABRICATOR MORE THAN DOUBLES EFFICIENCY

“… most importantly, my customers have noticed the difference as well. We have been able to deliver better more consistent finished product quality, complete the production and delivery much faster, and reduce the price that we charge. We have never been more competitive, and my customers have never been happier.”

— Terry Desrochers, Estimating Department Head, J. Oskam Steel Fabricators

ENHANCING COATING EFFICIENCY WITH ADVANCED BLAST ROOM TECHNOLOGY

Northwest Pipe Company partnered with BlastOne to design and install a state-of-the-art blast room tailored to their specific needs. This custom solution has streamlined their coating operations, resulting in increased efficiency and improved product quality. The collaboration underscores Northwest Pipe’s commitment to leveraging advanced technology to maintain industry leadership.

— Northwest Pipe

ENBRIDGE OIL TANKS – SAVE $300,000 USING GMA TOUGHBLAST

By switching to GMA ToughBlast, our client used 5x less abrasive. With the high production rate, Enbridge saved over a day and a half on labor costs. Moreover, they saved $300,000 by using GMA ToughBlast abrasive.

— CL Coatings

ACHIEVING UNPRECEDENTED EFFICIENCY: FIVE TANKS BLASTED IN JUST 30 DAYS

A recent project set a new standard in surface preparation efficiency by successfully abrasive blasting five large storage tanks within a tight 30-day timeframe. This remarkable accomplishment was made possible through the implementation of advanced blasting equipment and optimized project management strategies, demonstrating the potential for significant time savings in industrial maintenance operations.

REVOLUTIONIZING TANK COATING: COMPLETING 16-DAY PROJECTS IN JUST 6 DAYS

By integrating Qlayers’ advanced coating technology, a tank coating project that traditionally required 16 days was completed in only 6 days…

— Shell Deer Park

BOOSTING PRODUCTIVITY IN SPHERICAL TANK PROJECTS WITH VERTIDRIVE TECHNOLOGY

The implementation of VertiDrive’s advanced robotic blasting equipment has significantly enhanced productivity in spherical tank maintenance. This technology streamlines the surface preparation process, leading to reduced labor costs and improved safety by minimizing manual intervention. The result is a more efficient and effective approach to maintaining spherical storage tanks.

— Brock

Real Solutions. Real Impact.

See the Results!

Industry & Project Challenges

Pipelines need a durable and impermeable protective barrier to protect the surface from corrosion. These assets represent very high investments and if they become corroded sooner than expected, results in a loss of production and profits. Abrasive blasting is crucial to ensure the surface is ready for proper coating application and lengthening the life cycle of the coating.

Some common issues we’ve found from working with the industry:

-

-

High Maintenance Costs

Pipeline projects are often in very remote locations which will require all equipment to be transported to site. The whole site process, coupled with portability of equipment can be costly along with the restricted access to maintenance and repair equipment.

-

-

-

Delayed Project Timelines

Due to the remote locations of pipelines, any small delays due to incorrect equipment causes considerable downtime. This can create long-term delays to the completion of the project.

-

-

-

Workflow Disruptions and Labor Shortages

The joints of the pipelines must be welded before blasting or painting can begin. With labor shortages, project turnaround decreases.

-

-

-

Operator Safety Concerns

In-field blasting is typically around the piping joints, so the pipeline can be welded on site before it is put in the ground, particularly in the case of gas pipelines. Each weld needs blasted and coating of the weld margin usually a few inches either side of the weld. These pipelines are often buried, and if there is a pipeline failure, it is expensive to detect and repair a leak.

-

Oil & Gas Resources

Fastest Tank Turnarounds

Learn how BlastOne’s Performance3 Strategy can help you complete tank maintenance faster, safer, and at lower costs. This brochure highlights cutting-edge technologies like VertiDrive™, SnakeBite™ Nozzles, and Qlayers™, showcasing real-world case studies with efficiency gains of up to 900%.

25 Important Considerations when Building a Blast Facility

If you are purchasing a turnkey blast room for building it yourself, there are 25 subjects you need to be well versed in. BlastOne has compiled a detailed report containing an in-depth guide on all the critical components of a blast room: design considerations, abrasive education, and production techniques.

Knowledge & Learning

Videos from the Experts

How to | Primed Insights | Safety Tips

3 Reasons Why Blasters and Painters Should Have a UV Light

Chloride Field Testing Demonstration

Fairhaven Shipyard Testimonial

Industries Served

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account