ABOUT MAGUIRE IRON

Maguire Iron is a renowned leader in the water tower manufacturing industry. With decades of experience, the company has built a solid reputation for quality craftsmanship and innovation. Maguire Iron takes pride in delivering solutions that not only meet but exceed industry standards, specializing in the design, construction, and maintenance of water storage tanks across the United States. Their commitment to excellence has made them a trusted partner for municipalities and private industries alike.

PROJECT OBJECTIVE

Maguire Iron sought to upgrade their existing blast booth to leverage advanced automation for improved efficiency and productivity. Their primary objective was to make their system “robot ready” by incorporating state-of-the-art robotic blasting capabilities while keeping costs manageable by reusing components of their previous BlastOne installation, which was only 10 years old. They aimed to significantly boost productivity, increase blasting speed, and improve precision in handling large water tower components.

BACKGROUND

The existing blast booth, a BlastOne installation, had been serving Maguire Iron for the past decade. Despite its reliability, the booth required an upgrade to align with Maguire Iron’s goals of incorporating modern automation into their production process. They needed a solution that would provide precision and consistency far beyond manual blasting, allowing them to handle larger components and ensure high-quality finishes while adhering to tight project timelines.

CHALLENGE

The main challenge for Maguire Iron was to modernize the capabilities of their blast booth while maintaining budget efficiency. They were determined to implement advanced automation—specifically robotic blasting—without a complete overhaul of their existing infrastructure. This meant reusing as many parts of the original blast booth as possible while enhancing its capabilities to handle larger components of water towers with greater speed and accuracy.

SOLUTION

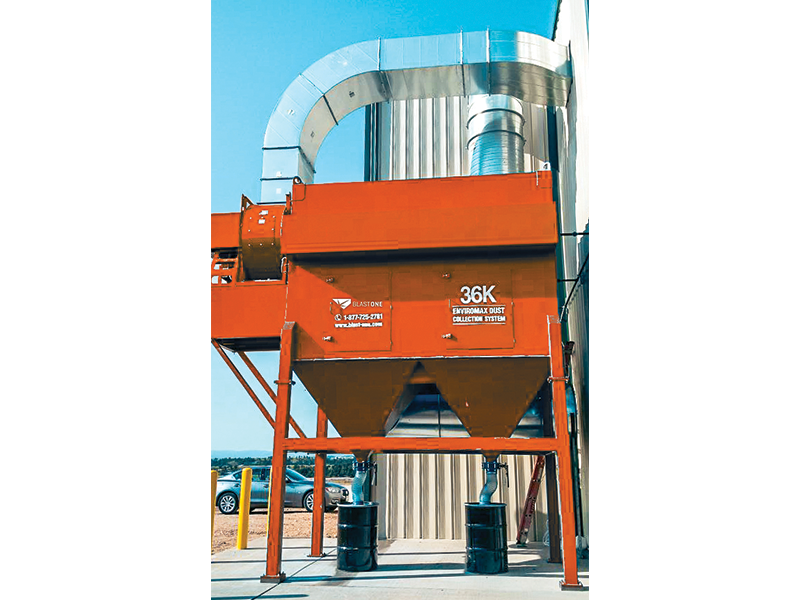

BlastOne developed a cutting-edge solution tailored to Maguire Iron’s needs. The core of the upgrade involved the installation of a Blastman robotic blasting system. This high-powered robotic blaster, equipped with two large blast nozzles, was capable of delivering precision and speed unattainable through manual blasting methods. The Blastman system allowed Maguire Iron to achieve a more uniform finish on each component, covering larger surface areas rapidly and efficiently.

To further enhance the facility, BlastOne also upgraded the abrasive recovery and recycling system. This improvement increased both environmental and operational efficiency by reducing waste and optimizing abrasive use. By retaining parts of the original booth—including the booth panels and other foundational components—Maguire Iron managed to significantly cut costs while simultaneously maximizing the performance of their upgraded system.

The integration was completed with minimal disruption to the existing operations, thanks to meticulous planning and phased implementation that allowed Maguire Iron to maintain ongoing production.

RESULTS

The results of the upgrade were transformative. The new robotic blasting system increased productivity tenfold, drastically reducing the time required for each blast cycle. Maguire Iron can now handle large sections of water towers with ease, enabling faster project turnarounds and enhanced production capabilities.

The precision and consistency delivered by the Blastman robot have not only improved the quality of each finished component but have also reduced rework and material waste, resulting in significant cost savings. Maguire Iron has expressed satisfaction with the new system, noting how it positions them as an industry leader in water tower manufacturing, capable of tackling larger and more complex projects with confidence.

The upgraded blast booth, now fully equipped with advanced automation, has strengthened Maguire Iron’s competitive edge. They have successfully transitioned to a state-of-the-art production facility, ready to meet the evolving demands of their customers while setting new standards in efficiency and quality within the industry.

CASE STUDIES

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account