Understanding Differential Pressure

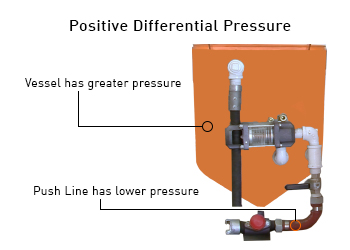

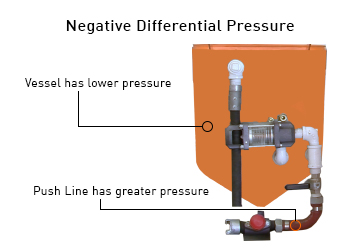

Differential pressure is a key concept in diagnosing issues with pressure release pots, and it comes in two forms: positive and negative. Each form produces distinct symptoms that can help you troubleshoot and resolve problems effectively.

Understanding how a balanced blast pot operates is essential for recognizing when differential pressure issues arise. A balanced system maintains equal pressure in both the vessel and the push line, ensuring smooth operation.

Balanced Pressure (Normative Operation)

In a properly balanced blast pot, pressure within the vessel and push line remains equal. Abrasive flows from the pot into the pressure stream, driven by gravity, which then carries the abrasive to the nozzle. This flow depends on the pressure in the push line, which feeds the abrasive smoothly to the nozzle, much like sand flowing through an hourglass.

My Account

My Account