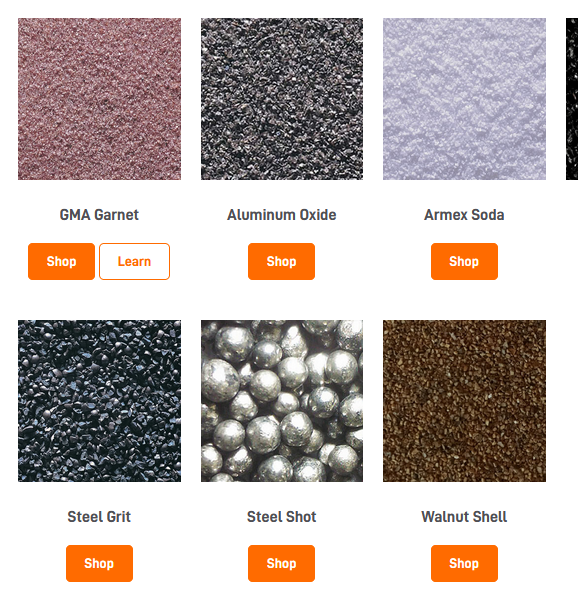

Selection of abrasive blasting media will have a massive impact on the performance of any blasting system and the overall profitability of the project. Choosing the correct media which is best designed for the environment, process being conducted or the result required will effect the overall cost and time of the project.

If you ever have any questions, call us, we are here to help you.

My Account

My Account