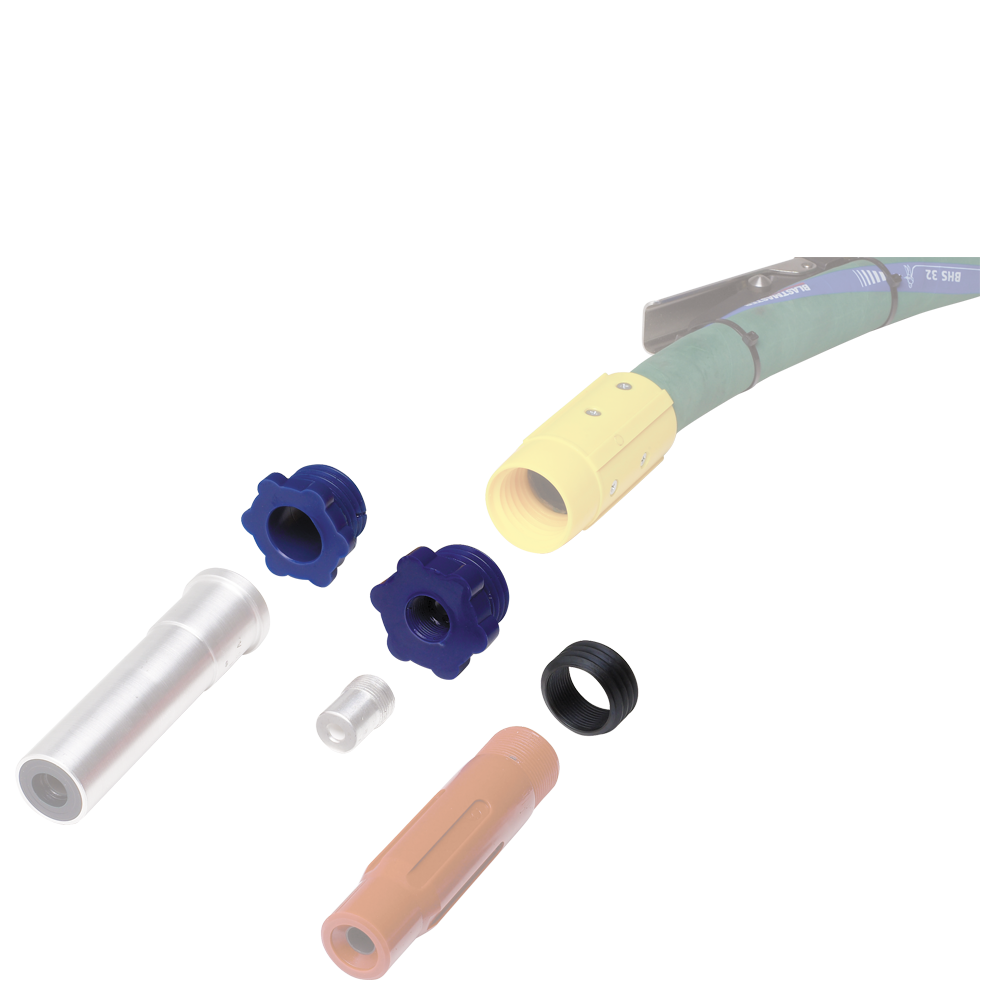

I have five different #8 blast nozzles. They’re all different and they all have different applications. The most common (nozzle) in the industry is what we call the TVP nozzle. It is a Tungsten Carbide blast nozzle which is great for your general purpose blasting. It’s very heavy and it does wear quite quickly. It’s been typically surpassed in the industry and replaced by the Ultratuff blast nozzle.

The Ultratuff has a silica nitride liner. Completely encased in urethane, it lasts twice as long and it’s about half the weight so it typically replaced the TVP tungsten carbide nozzle.

There are some other unique application nozzles worth talking about. The Bazooka nozzle here. This bazooka nozzle has a wider throat which means when you’re doing sweep blasting or blasting concrete for a decorative pattern, it provides you a very good consistent decorative pattern.

The hyper nozzle design has got a 30% longer exit which means the abrasives will speed up about 30% faster.

So when you’re moving tough coatings, the hyper nozzle is the best nozzle to use, or if you’re trying to blast at a further distance; like you’re blasting a tank floor and you want to stand upright versus bending all the way over. That’s where the hyper nozzle was used. Finally we have the Snakebite XQ blast nozzle. This blast nozzle has a silencer on it which will reduce the noise pollution coming from blasting by 75% (versus all these other nozzles). So if you’re working and you’ve got noise complaints the Snakebite nozzle is a solution for you. So if you’re working in a facility where you’ve got other workers, other trades working around you, you can reduce all noise complaints by using a Snakebite nozzle. It also reduces the kickback thrust on the blaster by 45%, which means they can use a larger blaster nozzle getting more work done, and have reduced fatigue.

Just talking about wear life:

* this Raptor nozzle will last you about 400 hours

* the general purpose TVP nozzle lasts about 250 hours

* expect the ultra nozzle to last about four to five hundred hours

* the hyper four to five hundred hours

* and we expect the snakebite XQ to last 500 hours

Most nozzles last about the same except for the tungsten carbide nozzle (the heaviest nozzle, the hardest to use) is only about 250.

There we have it five number eight blast nozzles from blast one you can order them all online today thank you very much.

My Account

My Account