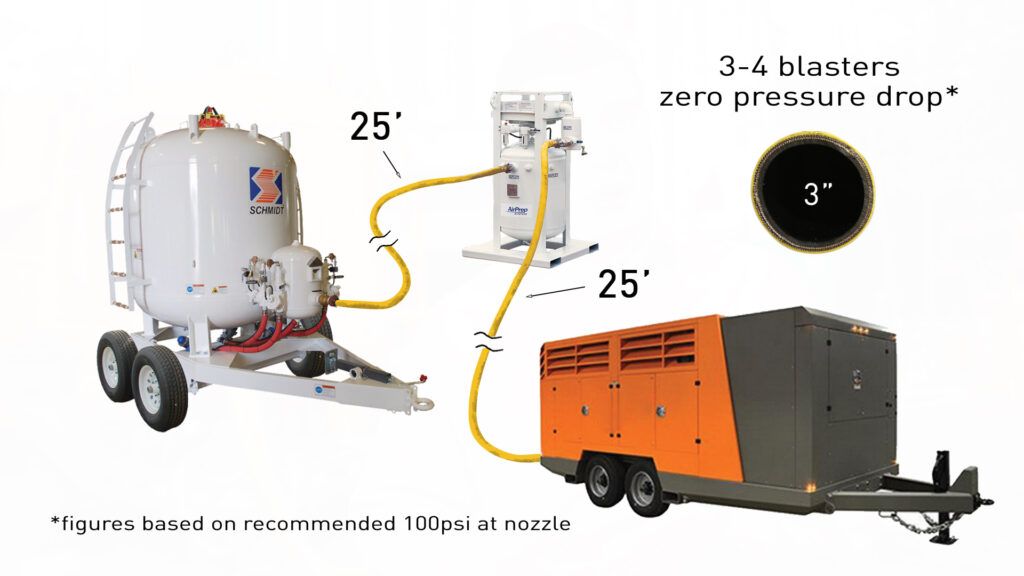

SWAPPING A SINGLE BULL AIR HOSE CAN SAVE DAYS OF LOST PRODUCTIVITY

In this Primed Insight we’re explaining how switching out a single air supply hose can increase blasting productivity by 12% each day.

HOW?

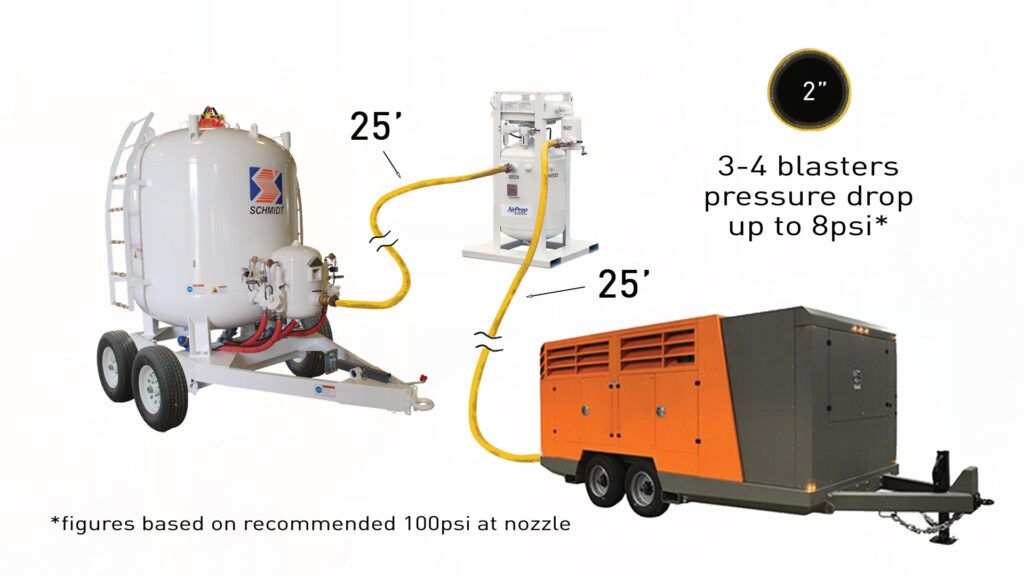

A typical set-up of this nature employs a 2 inch air supply hose coming from a 1600 cfm compressor, flowing into an air dryer, and then to the MegaBlaster. These two hoses generally run a minimum of 25 feet each – thus 50 feet total.

My Account

My Account