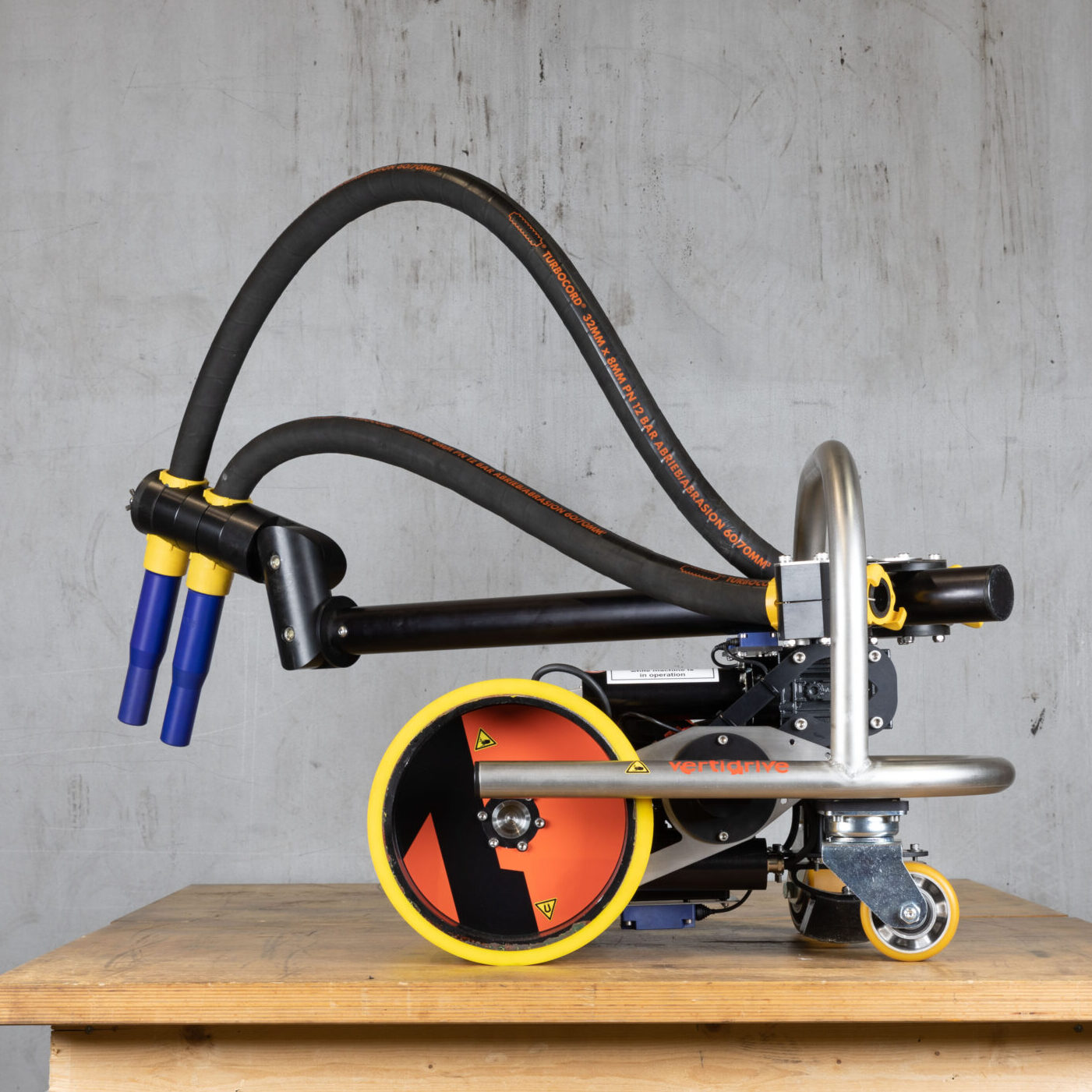

How Qlayers 10Q Robot Cuts Tank Downtime and Boosts Coating Efficiency

The Problem: Slow and Labor-Intensive Traditional Methods

Manual coating methods, such as hand rolling or conventional spraying, are:

- Time-consuming: Completing large storage tanks can take weeks due to limited speeds of around 300-350 ft²/hr.

- Labor-intensive: Workers must operate at dangerous heights using scaffolding, leading to slower progress and safety risks.

- Inconsistent: Rework due to uneven coatings further extends project timelines.

Every extra day of coating means:

- Production interruptions

- Delayed deliveries or operations

- Higher labor costs

- Reduced efficiency across the facility

The Solution: Qlayers’ High-Speed Robotic Coating Technology

Qlayers solves these challenges by completing coating projects up to 6 times faster than manual methods. Let’s compare:

| Coating Method | Speed | Project Timeline |

|---|---|---|

| Manual Application | 300-350 ft² per hour | Weeks for a single tank |

| Qlayers 10Q Robot | Up to 2,150 ft² per hour | Days instead of weeks |

With coating speeds of up to 2,150 ft²/hr, Qlayers drastically reduces the time required to complete projects. This speed advantage translates directly into less downtime for storage tanks, allowing businesses to resume operations much faster.

Benefits of Faster Project Completion

- Reduced Downtime Costs

Every day saved on coating reduces downtime-related expenses. For industries where tanks are critical to production, this can mean thousands of dollars in savings per day. - Increased Operational Efficiency

Faster coating allows for better project scheduling and minimal disruption to overall operations. Tanks are returned to service quickly, ensuring facilities stay productive. - Labor Cost Savings

Completing projects in days rather than weeks minimizes labor hours and associated costs, improving the project’s overall profitability. - Improved Coating Quality

With Qlayers’ robotic precision, there’s no need for rework or touch-ups, further streamlining the process and reducing delays.

A Real-World Example

Let’s consider a 250-foot diameter storage tank that would traditionally take 2 weeks to coat using manual spraying. With Qlayers, the same tank can be coated in just 3-4 days.

For businesses, this faster turnaround means:

- Significant cost savings on labor and downtime

- Quicker asset availability to meet production demands

- Enhanced ROI for coating projects

Key Takeaway

Qlayers’ 10Q Coating Robot is a game-changer for industries that rely on large storage tanks. By delivering faster coating speeds and consistent quality, it reduces project timelines and minimizes downtime—saving businesses time, money, and resources.

If you’re looking to keep your tanks online and operations running smoothly, Qlayers offers the fast, safe, and cost-effective solution you need.

Ready to reduce downtime and increase efficiency? Contact Us Today to discover how Qlayers’ robotic coating solutions can transform your next project.

Reduction In Paint Waste

Up to 50% less paint consumptions leads up to a 40% coating cost savings.

Safety

Reduce working hours at dangerous heights by up to 85%

Precision

Delivers finely-tuned alignment of paint carriage, delivering precise feathering between rows

Environmentally Friendly

Eliminates overspray & release of chemicals into the environment

My Account

My Account