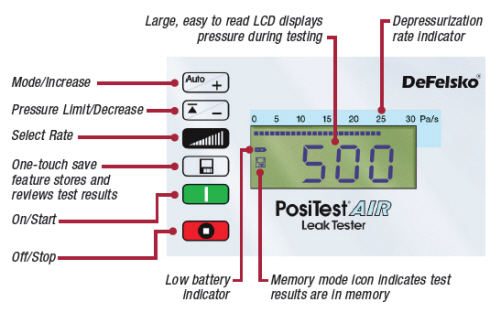

Air Barrier Leak Instruments Buying Guide

BlastOne, your trusted partner for inspection instruments, offers the innovative PosiTest® AIR Leak Detector for efficient air and water leak detection in building envelopes. This portable, hand-held tool simplifies the process of identifying leaks in various materials, including single and two-ply membranes, liquid-applied membranes, and more.

The PosiTest® AIR Leak Detector conforms to ASTM E1186, a standard test method for determining air leakage performance of building envelope assemblies. This ensures the accuracy and reliability of your leak detection results, meeting industry standards for building envelope performance.

My Account

My Account