VERTIDRIVE REDUCES LABOR COSTS AND SAFETY RISKS

LINDEN, NEW JERSEY

My Account

My Account

Catalog | Locations | Bulk Order | Quote List

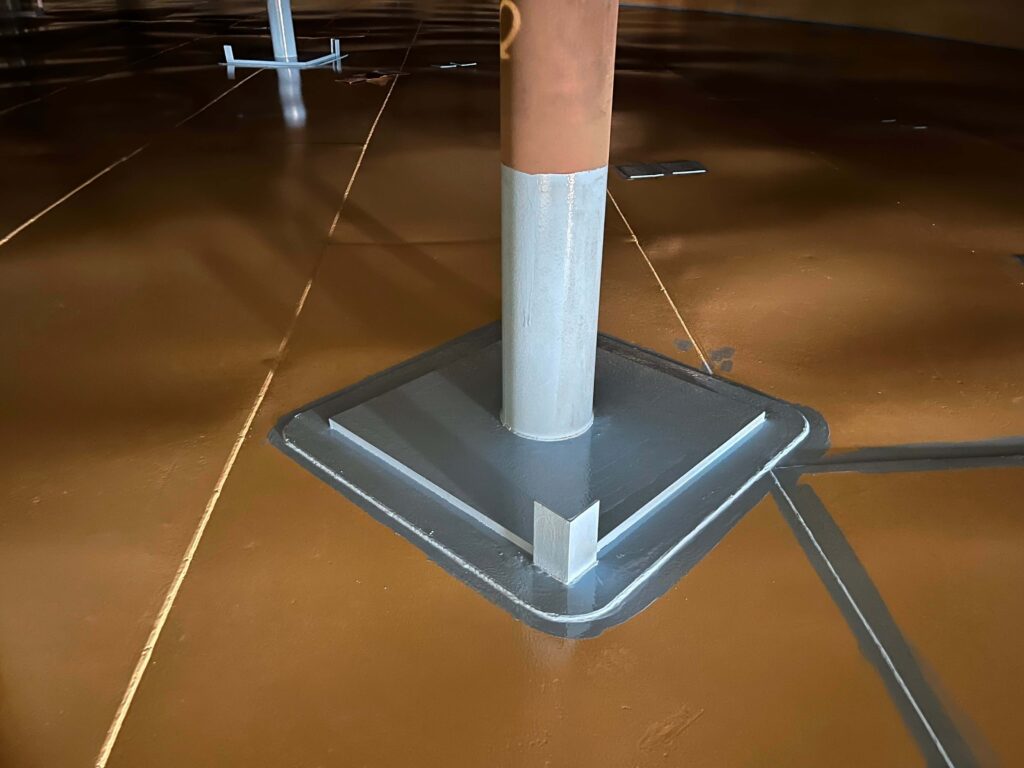

Tank 32001 at SunocoLP’s fuel distribution terminal in Linden, New Jersey, stands as a critical component in the gasoline distribution network fueling New York City. Despite its unremarkable appearance, the tank’s role is essential, and its upkeep is paramount. When the tank was due for its API 653 inspection in early 2023, it was discovered that the interior lining was failing, necessitating a comprehensive refurbishment. The project required strong teamwork, innovative technology, and effective material selection to meet the owner’s tight deadline.

Key tasks involved:

– Solvent cleaning per SSPC SP-1.

– Abrasive blasting with coal slag media to SSPC SP-10 standards.

– Applying Carboline’s Phenoline 311 as a holding primer.

– Using Phenoline Tank Shield FP to fill and seal pitted areas.

– Stripe coating weld seams, corners, and edges.

– Finishing with Phenoline Tank Shield.

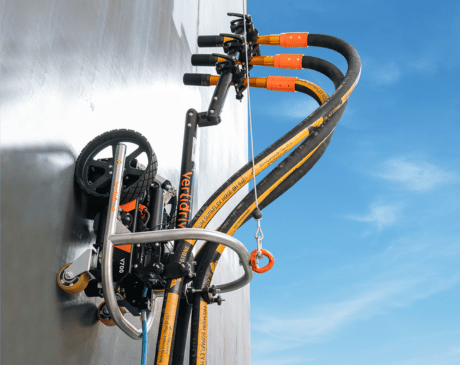

To enhance safety and efficiency, the team considered using a robotic abrasive blaster. BlastOne International introduced the VertiDrive M2 remote blaster, which traveled across tank surfaces with a long extension arm holding the blasting head. This robot reduced manhours and minimized the need for direct human contact with the tank surface, significantly lowering safety risks.

Calvin Woodruff, General Manager of Water and Blasting Solutions, remarked on the robot’s efficiency: “It’s not fast but it’s efficient. Current blasters would typically get fatigued and have to change out often. The VertiDrive M2 doesn’t get tired.”

Looking ahead, innovations such as improved vision systems and AI integration are expected to enhance the performance of robotic systems further. Brian continued, “I foresee that the future is definitely going to be automation with robotic painting and blasting.”

The refurbishment of Tank 32001 not only met the high standards of SunocoLP but also received technical support and recognition from the Association for Materials Protection and Performance (AMPP). With its new lining expected to last two decades, Tank 32001 stands as a testament to the benefits of incorporating robotic technology in industrial maintenance, setting a new standard for safety and efficiency in the field.

Learn how the VertiDrive Abrasive Blast Robot can streamline your surface preparation projects.

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

Registration is required to create a Quote.

Click Here to Login or Register.