Nozzle pressure is everything

For standard efficiency and productivity our experience tells us that a minimum of 100 psi is needed coming out at the nozzle. Each drop of 1 psi causes a corresponding drop of 1.5% in blasting speed. Many blasters read the compressor gauge and believe that to be their actual blasting pressure; which is totally false in nearly every single case we’ve examined.

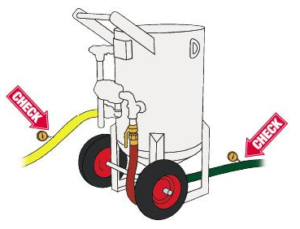

The Proper Way To Test Your Blast Pressure

With a BlastOne Pressure Gauge Kit, you can simply measure your blasting pressure. While the abrasive flow is open follow these 3 simple steps:

- Insert hypodermic needle onto nipple at the bottom of the gauge.

- Slowly insert the needle into the rubber hose a few inches back from the nozzle holder. Aim the needle toward the end of the nozzle, at a slight angle. Insert slowly until you get a constant reading. Are you getting 100psi?

- Record reading and remove needle. Pack away for next time.

My Account

My Account