VertiDrive V700 Blasting Robot

Sku: RUBVDV700

On large steel surfaces and structures the VertiDrive V700 Blasting Robot is the industry standard when it comes to providing the most comprehensive cleaning and blasting solution. Cost-efficient and timely removal of industrial coatings, corrosion and similar contamination on large steel surfaces like ship hulls and storage tanks is a monumental challenge. Site workers are able to operate more safely and efficiently - which ultimately translates to lower costs! Operator safety is ensured via the V700's ability to be wirelessly controlled at distance. How is the V700 Series different from the M7?- Stronger Motors (140W vs 315W)

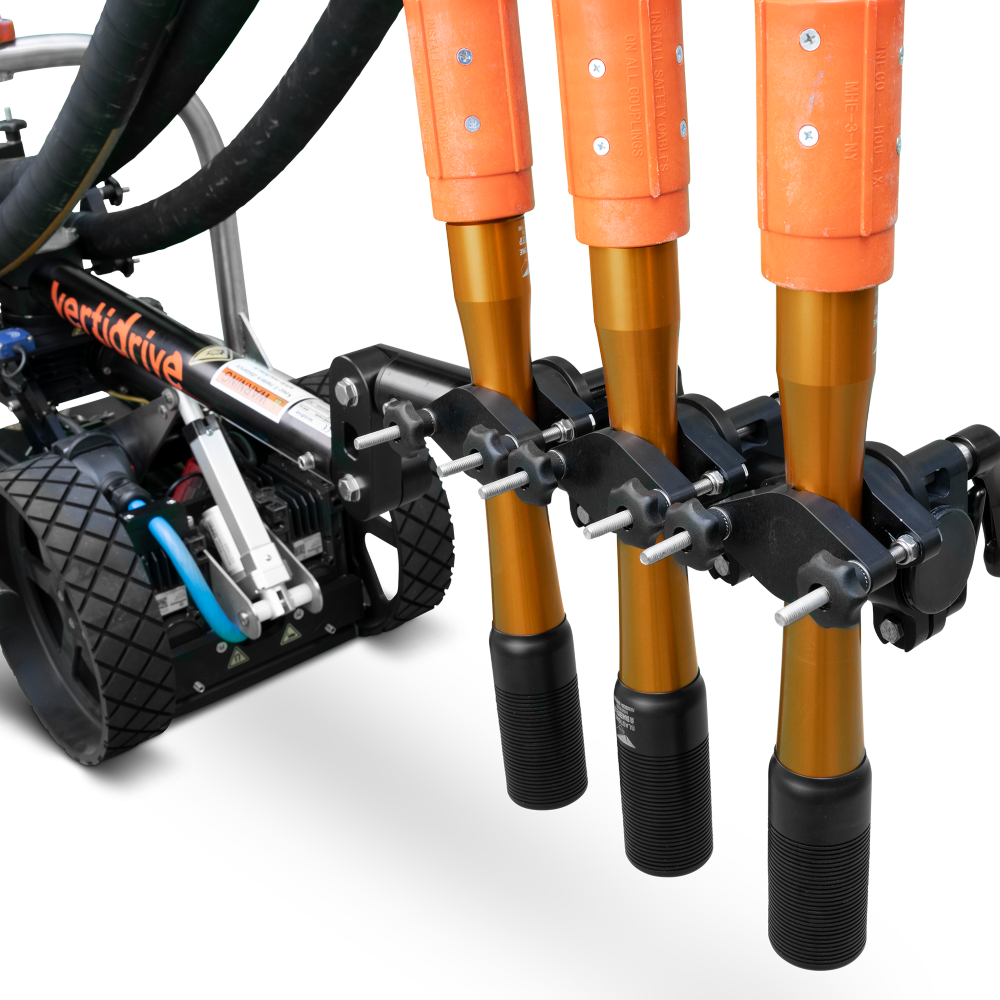

- The stronger 315W motor means the Vertidrive V700 can use 3 x SnakeBite XQ #10, an increase from 3 x SnakeBite XQ #8 – Increased productivity!

- Carries a greater payload of 150kg, an increase from the previous 100kg payload.

- Work 50% of capacity – lower maintenance cost

- Improved Frame Design

- The V700 has a more robust, suitable for harsh industrial environments

- The new cooled control box option means the Vertidrive can be used above 35 degrees Celsius without overheating.

- Enhanced frame design leads to easier maintenance

- Stronger Rear Magnet

- The stronger magnet at the rear of the V700 provides a greater ability to drive upside down.

- Adjustable Magnet Distance

- Allows the V700 to traverse easier welds and other obstacles e.g. It is easier to use on a tank floor with steel plates welded over each other.

- Higher heights – Payload

- Allows further optimisation per application

- Improved swing arm support

- Allows the use of higher pressures at the UHP or blast nozzle. Higher thrust on the swing arm = higher performance!

- Increases the lifetime of the gearbox due to lower load on the gearbox

- Maintenance costs are lower

- Up to 50% lower OPEX cost due to improved design, new motors, swing arm support etc.

- Downtime is reduced which means more blast/operational time

My Account

My Account