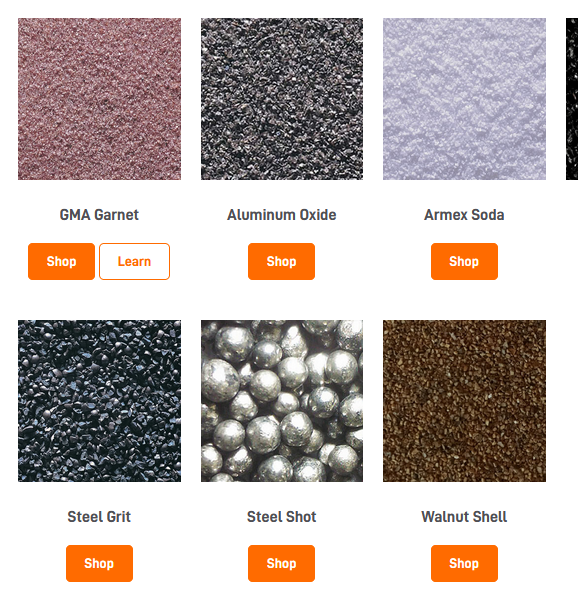

Steel Shot

Sku: P-AMS

Steel Shot is a highly effective abrasive or peening media for creating a shot blasted profile free of contamination that causes rust. Steel Shot is used in airless wheel blast machines to clean foundry castings, shot blasting of steel structures and for surface finishing to impart a more polished surface to metallic objects. Available Grades of Steel Shot:

- S110 Steel Shot - 0.012" - 0.02" (0.3 - 0.5mm)

- S170 Steel Shot - 0.0168" - 0.0284" (0.42 - 0.71mm)

- S230 Steel Shot - 0.024" - 0.034" (0.6 - 0.85mm)

- S280 Steel Shot - 0.0284" - 0.04" (0.71 - 1.0mm)

- S330 Steel Shot - 0.034" - 0.048" (0.85 - 1.2mm)

- S390 Steel Shot - 0.04" - 0.056" (1.0 - 1.4mm)

- S460 Steel Shot - 0.048" - 0.068" (1.2 - 1.7mm)

- S550 Steel Shot - 0.056" - 0.068" (1.4 - 2.0mm)

- S660 Steel Shot - 0.068" - 0.092" (1.7 - 2.3mm)

- Other sizes of steel shot are available

What is the correct size of steel shot to use? Industry experts agree that the best size steel shot to use for any given application is the finest grade that will do the work & create the desired outcome & surface finish. If the steel shot abrasive is too coarse, it can peen & clean too slowly, as well as leave an excessive or rough surface profile. It is recommended you contact your steel shot supplier.

Why BlastOne is the leading Australian steel shot supplier: There are many steel shot manufacturers around the world, but there are no steel shot manufacturers in Australia. BlastOne sources steel shots from reputable manufacturers who have demonstrated consistently high-quality & long-lasting products over many years. BlastOne has been a supplier of steel shot in Australia for over 30 years.

Why do some steel shots last longer than others? The metallurgical composition of steel shot & the heat treatment, are vital to its life expectancy. Good quality steel shot has very low levels of phosphorus & carbon. A majority of steel shot is made from recycled (scrap) metal, the source of the recycled metal is critical to the composition and thus the quality/life expectancy of steel shot. Steel Shot Hardness

Which is the correct hardness steel shot to use? Steel shot comes in a variety of hardness. Generally hard steel shot is used in peening applications & normal steel shot is used in blast cleaning applications. Hard steel shot breaks down quicker than normal hardness shot, so requires a steel shot sieve or air wash in the steel shot abrasive recycling system, to ensure the shards & broken down shot particles are properly removed before reuse. This ensures the shot peening surface is not compromised with nonspherical steel shot particles. Safety Data Sheet for Steel Shot - see download link under Document Downloads Tab. MSDS Steel Shot.

When should I dispose of the Steel Shot? At what size will worn down steel shot be ineffective? Abrasive Separator settings for Steel Shot As a rule of thumb, the abrasive separator on your shot blast machine should be set to remove steel shot particles when they are worn to the following parameters Shot peening - 50% of original steel shot size Steel surface preparation - 25% of original steel shot size BlastOne has screen sets available to enable steel shot users to quickly check the particle size of their steel shot working mix, and the fine steel shot particles removed by the abrasive cleaner on the shot blast machine, so adjustments can be made to enhance blasting & peening efficiency

My Account

My Account