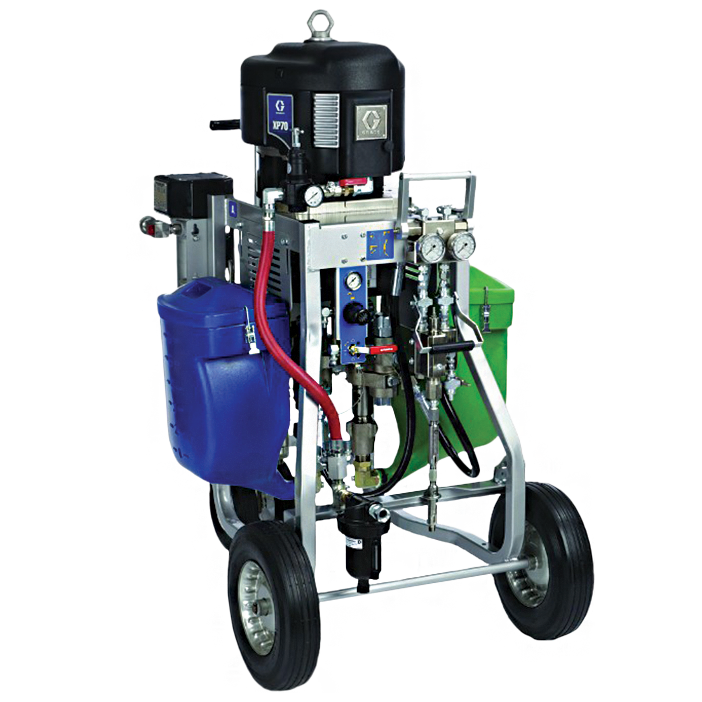

Industrial Painters Spray Guns Buying Guide

Explore and compare the BlastOne line of top industrial spray guns including Tritech, Binks, DeVilbiss, and Graco. Whether you are needing an airless or conventional spray gun, BlastOne offers something for project and within your price range.

Should you have a specific question or need advice, please don’t hesitate to reach out to our customer service.

My Account

My Account