BACKGROUND

VT Halter Marine is a leader in the design and construction of medium-sized ships in the United States.

With tightening environmental controls and a growing order book, VT Halter needed to diminish its environmental footprint, decrease reliance on good weather, and increase production in its blast and paint operations.

SOLUTION

BlastOne worked with VT Halter engineers to design and build a new advanced technology blast and paint facility to suit some very custom requirements. The overall blast & paint facility consists of a large 304’ x 120’ (90m x 36m) main building that is divided into a 150-foot blast hall and a 150-foot paint hall. Subsequently, this facility accommodates ship sections as large as 105’ W x 80’ L x 40’ H, weighing up to 500 tons each.

Adjacent paint room to paint small parts

Now capable to operate 24/7 in all weather conditions

The facility includes dehumidification to maximize the number of operating days

The facility uses BlastOne's unique approach to recirculating flow in both paint and blast halls - reducing energy consumption and operating costs by $500,000+

Reduction of energy consumption and carbon footprint by implementing 100% LED lighting

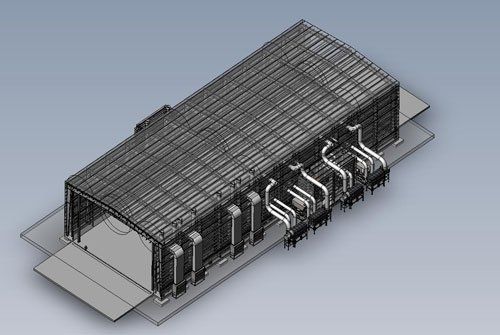

Blueprint design of VT Halter’s massive Blast/Paint facility

“The installation of this new blast and paint facility incorporates cutting-edge technologies in our marine construction programs which now allows us to apply a diverse range of protective coatings regardless of the weather conditions.” – Rob Mullins, Chief Executive Officer of VT Halter Marine

“BlastOne’s engineering and equipment have enabled us to cut our particulate emissions to zero while doubling our productivity. VT Halter Marine is delighted by the finished facility.” – Tim Pryor, Facilities Manager of VT Halter Marine

RESULTS

VT Halter finally has a serious competitive advantage over many of its competitors.

VT Halter’s massive blast and paint facility

Makeup air unit installations to channel heated air to aid paint curing

Blasting sector of new facility

The front of the new blast and paint facility

The facility installed high capacity dust collector units

Large dividing door to separate blasting from painting operations

CASE STUDIES

KNOWLEDGE & LEARNING

5 CRITICAL COMPONENTS OF A BLAST ROOM

4 WAYS TO CURE PAINT FASTER

THE PROPER EQUIPMENT FOR EACH COATING

Contact BlastOne

We love to talk to customers and help them make the best decisions when purchasing equipment.

You can reach us via our Live Chat, Email, Phone, and Online Form.

My Account

My Account